This plastic thermoforming machine is a kind of equipment that heats and softens the sheet or film, and processes the product into various shapes through the mold. They are widely used in pharmaceutical packaging, food packaging, daily chemical products, electronic device trays, hardware tool packaging, toy shells, and other industries, as long as plastic products are needed to form, they usually can not do without this

The plastic thermoforming machine heats the plastic material to make it soft, then uses molds to shape it and cools it to set, transforming the material into the desired product shape, achieving continuous and automated processing. These videos showcase the entire workflow. Please enjoy them.

Suitable for plastic cup lids, plastic food containers, plastic bowl covers, medical trays, food trays, stationery trays, hardware trays, electronic trays, auto and motorcycle parts, daily necessities, cosmetics, and so on, plastic packaging products for disposable products.

The plastic thermoforming machine is used to produce food trays, packaging boxes and sealed containers, ensuring food hygiene, safety, uniform appearance and facilitating transportation and display.

The plastic thermoforming machine can produce tool trays and packaging shells for hardware, enhancing product protection, presentation effect and facilitating transportation and storage.

The plastic thermoforming machine can be used to manufacture toothless packaging trays and covers, providing safety and scratch protection. At the same time, it enhances the display quality and transportation stability of the products.

The production capacity of a plastic thermoforming machine is usually distinguished by the number of forming operations per minute, the hourly output, or the number of single mold cavities. The capacity can be described by terms such as “forming speed”, “cycle times”, and “mold cavity count”.

Like this plastic spoon small size products, the machine can reach 2,100pcs/hour

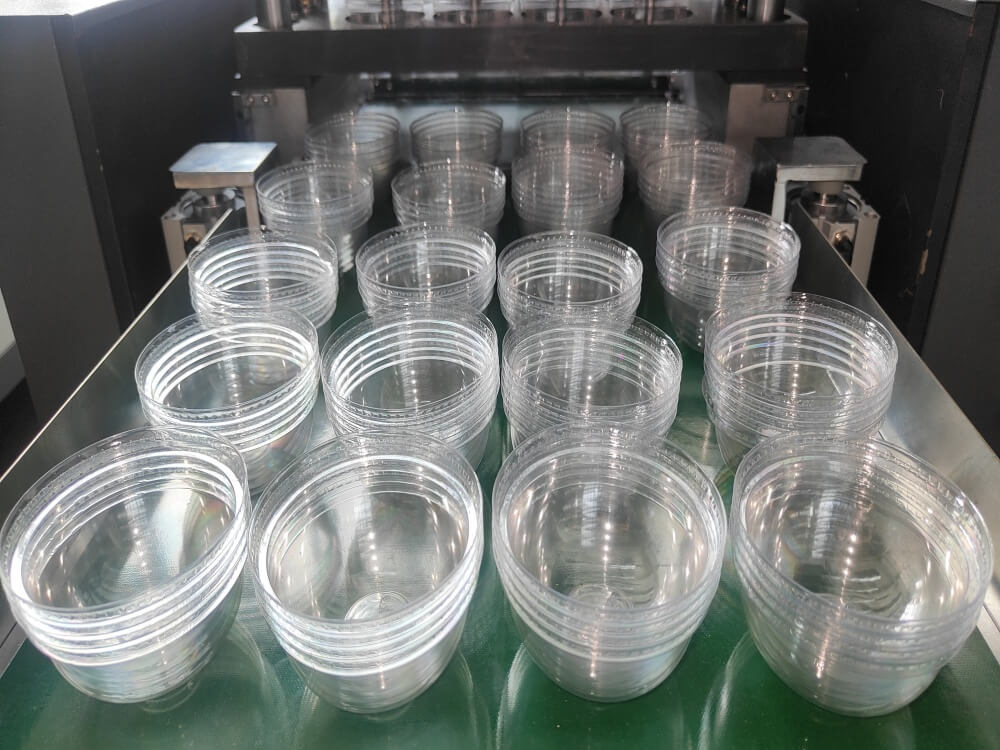

This big size plastic bowl, tray, the thermoforming machine can produce 1,200pcs/hour.

This plastic lid in mideum size, the thermoforming machine speed reach 1,800pcs/hour.

The plastic thermoforming machine can process various sheet materials, such as PVC, PET, PP, PS, ABS and PLA, etc. They cover transparent, high-strength, heat-resistant, low-cost and biodegradable materials, meeting the different needs of industries such as food, medicine, hardware and daily necessities. The equipment achieves stable forming and high-quality appearance for various materials by adjusting the heating and forming parameters.

Highly transparent, high strength, recyclable, suitable for display packaging of food and electronic products.

It has good processing properties and low cost, and is mainly used for metal trays, toy packaging, etc.

Biodegradable, environmentally friendly materials, suitable for food and environmental protection packaging fields.

Main function | PET, PVC, HIPS, etc, plastic products. Automatic forming, heat sealing and cutting |

Application | It’s widely used in the PET/PVC/HIPS plastic lids, medicine/food/daily/electronics/hardware, etc, production |

Speed | 15-35cycle/min |

Material | PVC/PET/HIPS/PLA |

Total Power | 4KW |

compressed air | Compressed air with 0.6-1.0 MPa pressure |

Air consumption | >0.6m³/Min |

Water chiller for moulds | 60L/H Tap water or recycled water with 60L/H consumption |

Max Forming width | 130mm |

Max making Length | 450mm |

Max making depth | 46mm |

Overall dimension | 2950*1100*1700mm |

Weight | 1100kg |

Plastic Thermoforming Machine Process flow:

→ Unroll → Heat → Plastic molding → Product drilling → Servo traction → Plastic tray cutting → Product stacking → Waste collection → Finished product output

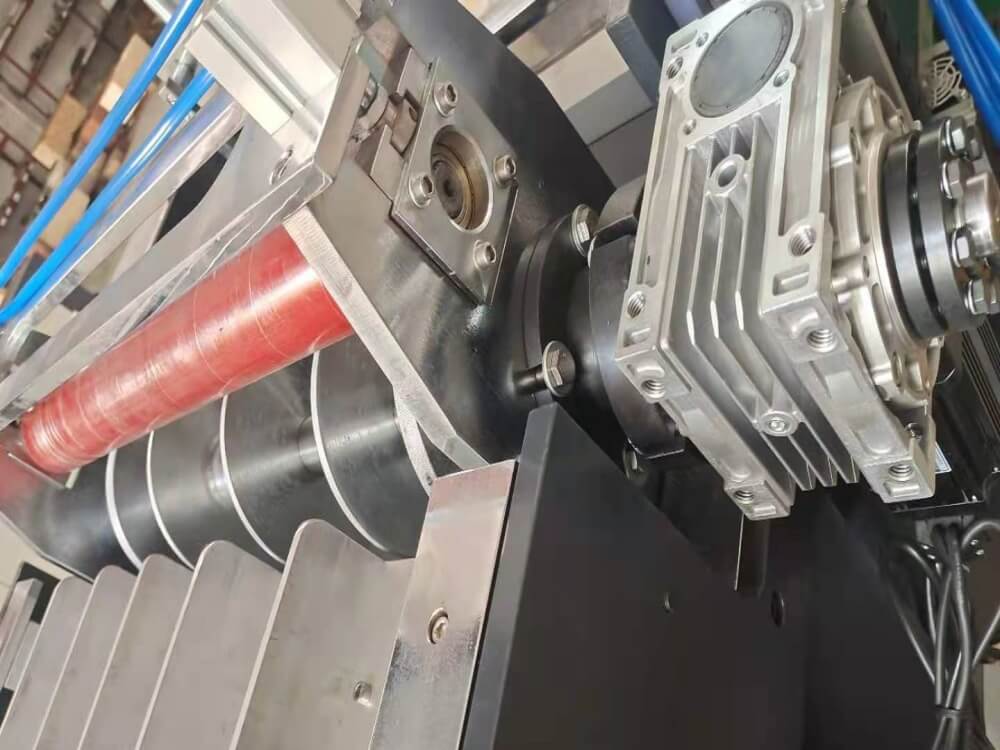

Unique design ensures more stable feeding. Our factory own technology, know more please contact us.

Two heating plates are used to heat the plates simultaneously, ensuring uniform temperature of the material and facilitating the formation of the shell, thereby guaranteeing product quality.

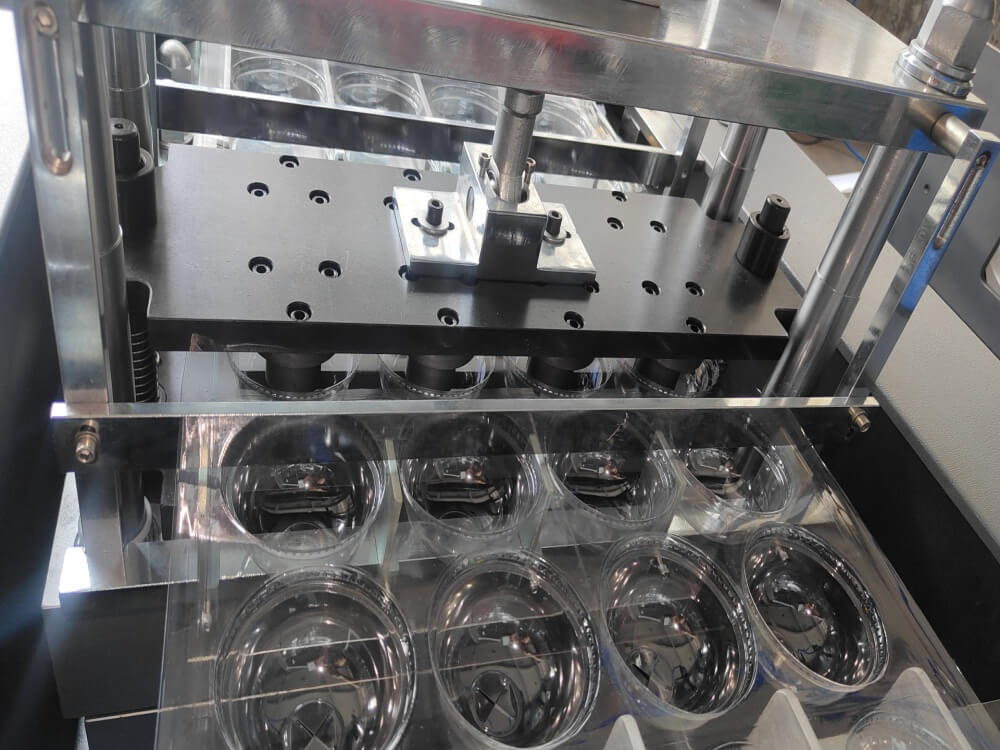

Cylinder-driven mechanical stretching combined with positive pressure blowing to ensure uniform thickness of the formed shell, making it more sturdy and attractive

The hardware knife is made from special mold steel is precisely processed by a machining center to ensure the durability of the blade and the absence of burrs on the four sides of the handle.

Using servo motors for traction ensures a more stable movement. The dimensions of the four sides of the plate are basically the same.

Finished products are stacked together, making collection convenient and reducing the labor force of workers.

Our plastic thermoforming machine is highly efficient and cost-effective – it can produce 30% more products than ordinary machines, significantly reducing your production costs. This equipment has extremely high precision and is equipped with an intelligent control system, which ensures that every plastic blister maintains consistency and reduces material waste.

It is compatible with various common plastic materials and can easily meet your different packaging needs. What’s more, it is very easy to use – just one button start, no complex training required, and very little maintenance is needed.

The thermoforming mold has a simple structure and a short manufacturing cycle, making it suitable for customizing products with multiple specifications, small batches, and various varieties.

The temperature control is precise, the thickness is evenly distributed, the product has high transparency and neat edges, making it suitable for display packaging.

The components have high compatibility, are easy to debug, require simple daily maintenance, and operate stably and reliably as a whole.

You can get a price of this model or send us any question to get any information you would like to know, we will reply to you soonest.