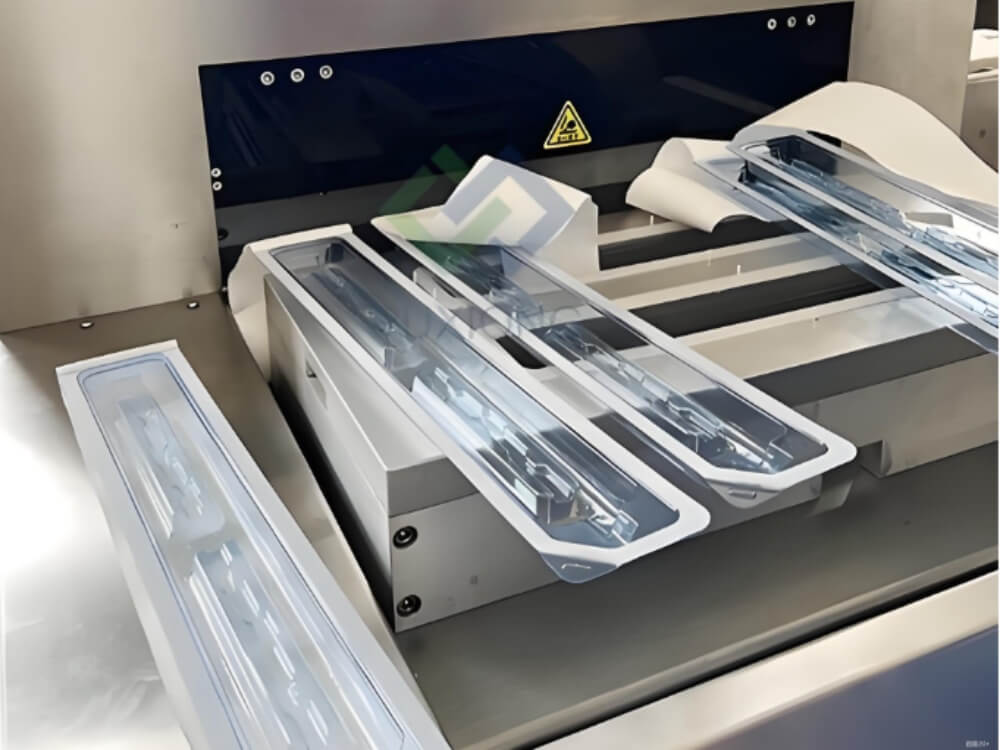

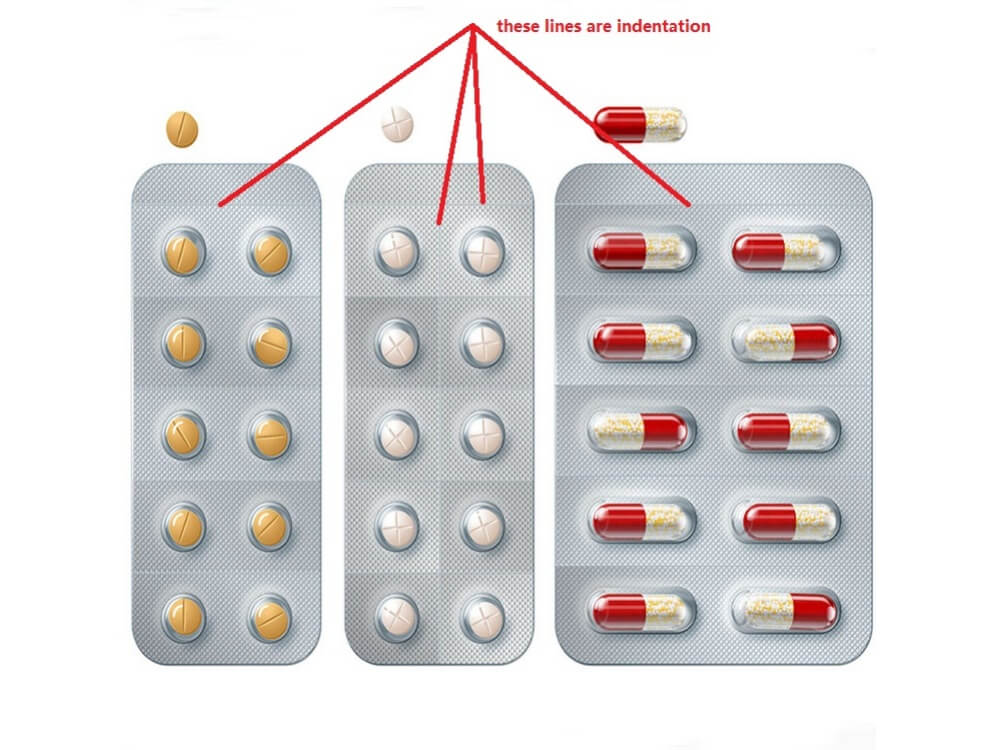

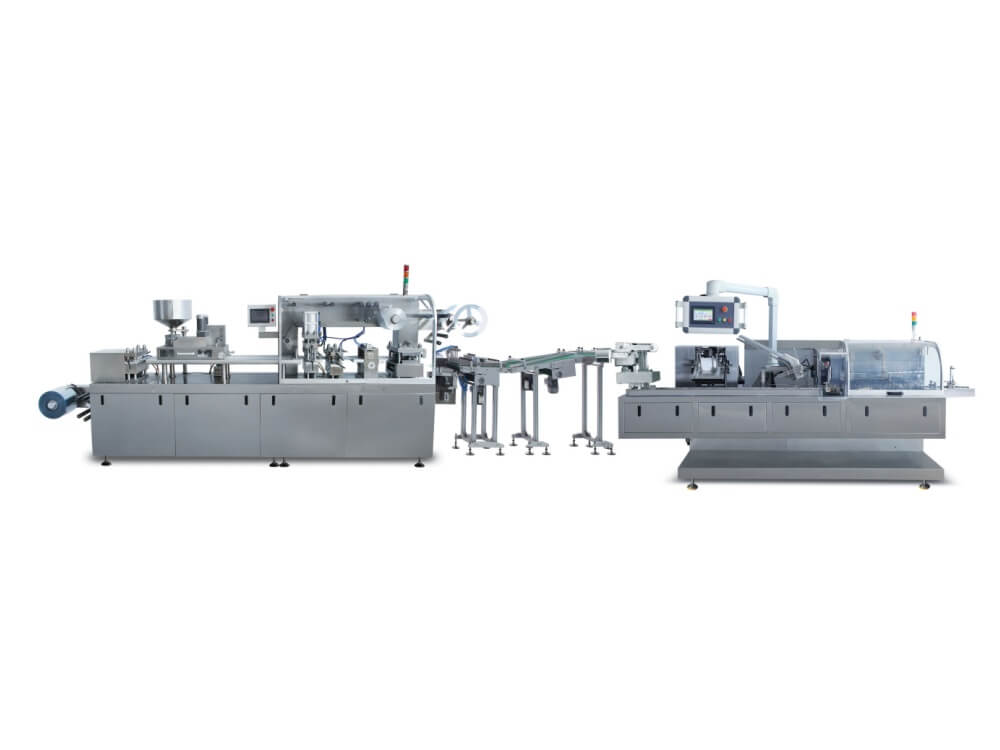

Designed for the pharmaceutical industry, it meets the sealed packaging requirements of tablets, capsules, pills, and other drugs. Achieves a balance between compliance and production efficiency. It is the core equipment of pharmaceutical enterprises in mass production.

Our pharmaceutical blister packaging machine can provide precise, hygienic, and GMP-compliant packaging for tablets, capsules, pills, and small medical devices.

It is highly suitable for pharmaceutical factories, laboratories, and outsourcing packaging businesses. These blister lines offer high precision and stable form-sealing performance, enhance drug protection, extend shelf life, and are suitable for PVC、PVDC、 aluminum-aluminum composites, and various pharmaceutical grade materials.

Our blister pack machine pharmacy is a thermoforming blister machine for pharma, integrating the cutting-edge technology in the industry, and carries out special optimization for the production pain points of pharmaceutical companies:

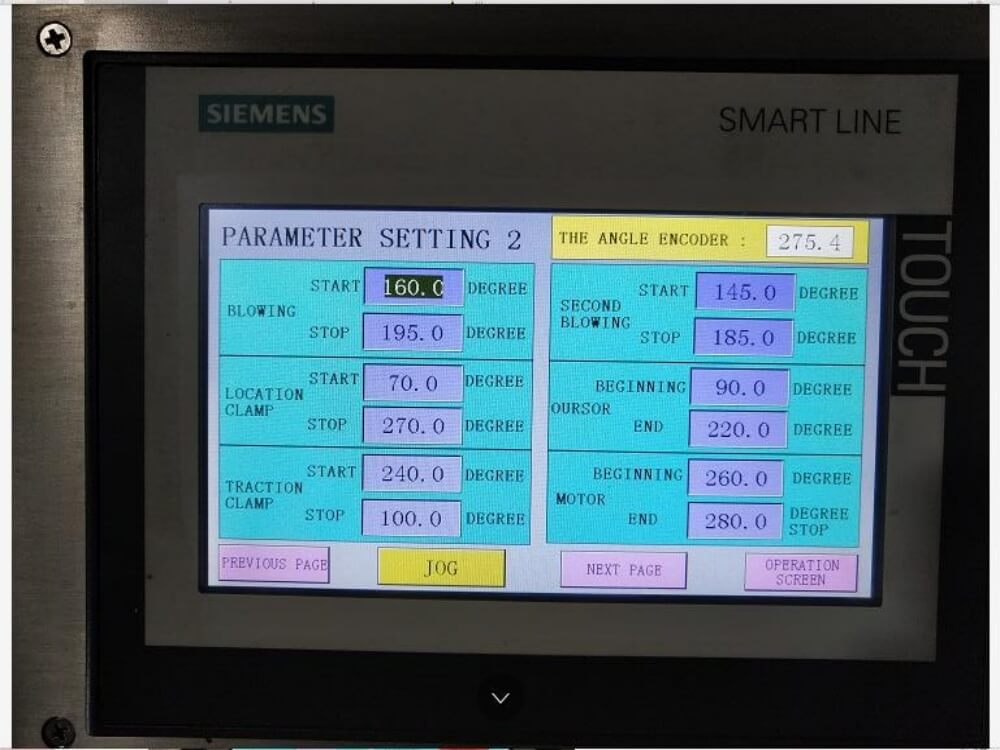

from raw material feeding, blister forming, drug filling, sealing, and pressing to finished product cutting, automatic control in the whole process to reduce manual intervention and pollution risk; equipped with an intelligent detection system, real-time monitoring of blister integrity, and drug filling volume, to ensure that each batch of products meets the quality standards.

Pain Points:

The medicine requires strict sealing to prevent moisture absorption and oxidation.

Solution:

DPP blister packaging machine driven by servo motors, the forming accuracy reaches ±0.1mm, the sealing strength is uniform, and the leakage rate approaches 0.

Pain Points:

The packaging must comply with GMP/FDA requirements.

Solution:

Pharmaceutical Blister Packaging Machine 100% compliance guarantee: Compliant with GMP, FDA, and CE standards, and meeting the requirements for drug packaging traceability

Pain Points:

Various specifications and numerous production batches

Solution:

Quick mold change structure: Reduces batch switching time and grows production capacity. Customize various specifications of blister molds, suitable for tablets, capsules, granules, and other pharmaceutical products.

Pain Points:

It is necessary to ensure high stability to prevent batch scrapping.

Solution:

Fully automatic feeding of capsules/tablets, detection of missing, rejection of defective products, and increasing yield to 99.8%. The packaging speed can be adjusted to meet different capacity needs.

Pain Points:

Medicines need strict hygiene and cleanliness. The difficulty in cleaning is a major problem.

Solution:

Pharmaceutical factory-level hygiene design: All made of stainless steel 304, with a planar layout, the surface has no dead corners and is easy to clean, in line with GMP clean workshop standards.

Pain Points:

To meet the requirements of integration. Can it be connected to other devices?

Solution:

The pharmaceutical blister packaging machine can be connected and coordinated with the feeding, detection, and cartoning systems.

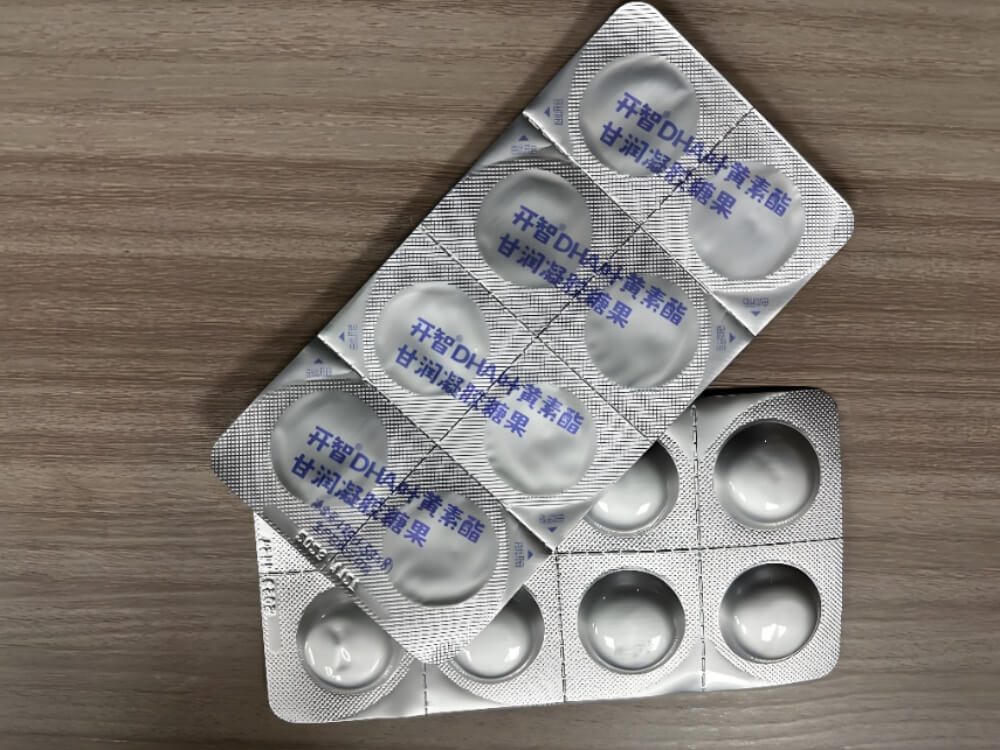

Blister Packaging Machine Pharmaceutical Industry meet strict pharma standards (GMP, FDA, CE). Made of 304/316L stainless steel, they have no residue corners, keeping drugs clean and helping pass audits easily.

They work for many drugs: moisture-proof film protects sustained-release tablets, custom curved molds and low-temperature sealing keep suppositories from breaking, and they fit regular tablets/capsules too. Mold changes take ≤30 minutes, good for small or large production.

Cleaning is fast—drug-touch parts disassemble tool-free in 5 minutes, full cleaning takes <1 hour (40% faster than old machines), saving time for multi-drug firms.

With a 7-inch touchscreen, operators set/save drug parameters easily. The machines run stably (≤0.5% failure in 12 hours), use 20% less energy. They also have good after-sales: 1-year warranty, 24/7 support. Overall, they balance safety, efficiency, and flexibility—great for pharma packaging.

Accurate forming & sealing, no leakage, locks moisture out, keeping drugs stable and safe.

High forming depth fits large/special drugs; clean cavity definition ensures no residue, meeting pharma cleanliness needs.

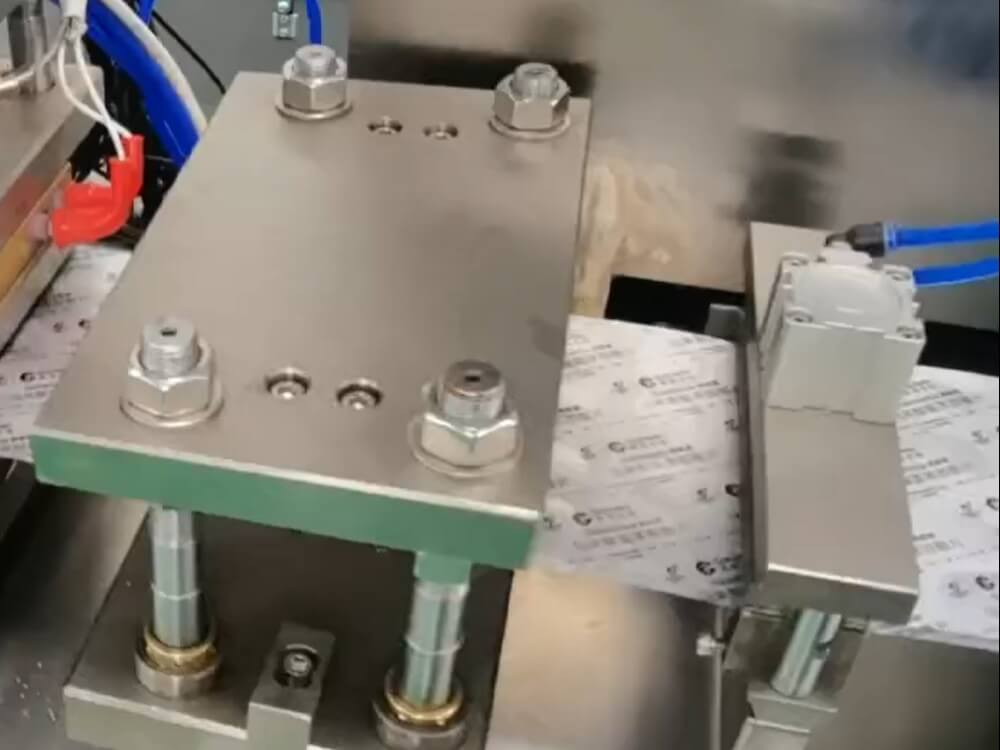

Keeps sealing temperature steady, to ensure medical-grade tight seals, and no drug moisture damage.

Smooth operation avoids drug damage, precise movement guarantees stable packaging quality.

Batch coding tracks drugs; perforation eases opening; embossing adds information.

Connect with cartoner—full-line auto, shortens workflow, raises pharma packaging speed.

CE/ISO/GMP compliance meets global pharma standards, easing market access and ensuring safety.

Model | Punches Frequency | Max. Forming Area | Forming Material | Machine Size |

DPP 80 | 10-33times/min | 105*70*12mm | PVC, PET, PS, PVDC, Alu | 1840*590*1100 mm |

DPP 150 | 15-35times/min | 140*100*16mm | PVC, PET, PS, PVDC, Alu | 2450*570*1550mm |

DPP 180 | 25-50times/min | 160*100*20mm | PVC, PET, PS, PVDC, Alu | 3050*590*1550mm |

DPP 250 | 25-60times/min | 250*120*20mm | PVC, PET, PS, PVDC, Alu | 4460*760*1620mm |

DPP 350 | 25-60times/min | 350*120*20mm | PVC, PET, PS, PVDC, Alu | 4460*860*1620mm |

Pharmaceutical blister pack machines are widely used in pharma for packaging tablets, capsules, sustained-release pills, and suppositories. They ensure safe sealing, fit GMP standards, and can connect to cartoners for full-line auto, boosting efficiency.

Pharmaceutical companies use blister packaging for various drugs to ensure protective effects, facilitate tracking, and achieve full-line automated production.

Health supplement firms use blister machines to pack vitamins, probiotics—seal well, control single doses, and fit diverse supplement forms.

Blister pack machines aid vet companies: protect vet drugs, fit diverse dosage forms, ensuring stable quality during use.

Research institutions use blister machines for small-batch drug trials—fit diverse samples, ensure precise packaging to support R&D.

The main structure of the pharma blister packaging machine includes: forming station, feeding system, sealing station, control panel (operates and monitors the machine), batch coding, punching, and finished blister out system.

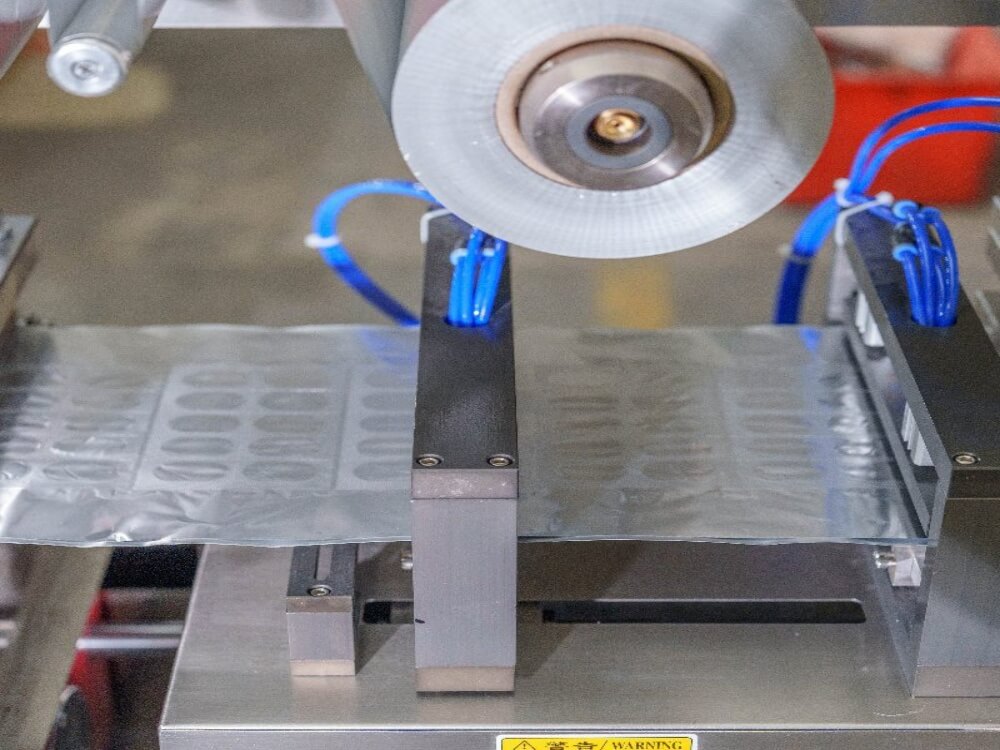

For shaping film into blisters. Two forming methods: Alu plastic thermoforming, Alu Alu cold forming.

Feeds drugs into blisters precisely, ensuring proper loading.

Seals blisters with lidding film to ensure tight, protective closure.

Codes batch details; perforates packs for convenient tearing

Cuts sealed blister sheets into finished, usable pack sizes.

Outputs completed blister packs steadily to ensure workflow continuity.

1.18 years of experience in the pharmaceutical machinery industry: Specialized in the research and production of pharmaceutical packaging equipment, providing services to over 500 pharmaceutical companies, among which 30% are special formulation production enterprises.

2. Customized solutions: For special requirements such as sustained-release tablets and suppositories, we offer a complete chain service including “mold design + process debugging + qualification support.”

3. Comprehensive after-sales service: 1-year warranty, lifetime technical support, 24-hour response to repair requests, and special formulation packaging process training.

4. Compliance Assurance: The equipment has obtained GMP certification. Independently developed core components eliminate intermediate links, resulting in a price 10-15% lower than that of competitors.

You can get a price of this model or send us any question to get any information you would like to know, we will reply to you soonest.