“Upgrade your production with our automated blister packaging machines, designed specifically for hardware like tools, fasteners, and spare parts. We know that manual packing is slow and expensive. That is why we build custom feeding systems that automatically load even the most irregular shapes into the packs. By replacing manual work with machine precision, you can significantly speed up your output and cut labor costs. It is the simplest way to boost efficiency and increase your factory’s profit margins.”

Cut Costs, Not Quality

Manual packaging for irregular hardware is slow and expensive. When you run a Cost Per Unit Analysis, labor is often the biggest expense. Our fully automatic blister packaging machine solves this by integrating forming, feeding, and sealing into one continuous process. This automation allows one operator to do the work of ten, reducing your labor cost per unit by 80% while ensuring every package is sealed securely and consistently.

Strong sealing technology ensures heavy tools (hammers, wrenches) stay secure.

We specialize in custom feeders for irregular shapes (hooks, clips).

“Choosing the right machine depends entirely on your hardware. Think of the Flat-Plate model as your ‘heavy lifter’—it’s perfect for deep, bulky items like hammers or wrench sets that need strong protection.

For sheer speed, the Rotary machine is unbeatable; it churns out small items like batteries, screws, or drill bits at a lightning pace.

Meanwhile, our Paper-Plastic series is your answer to global eco-trends, creating sustainable, plastic-free packaging that major retailers like Home Depot now demand.”

Deep forming sutis to deep draw, heavy-duty tools, large format.

High speed with large outputs, suits to small items such as batteries, screws.

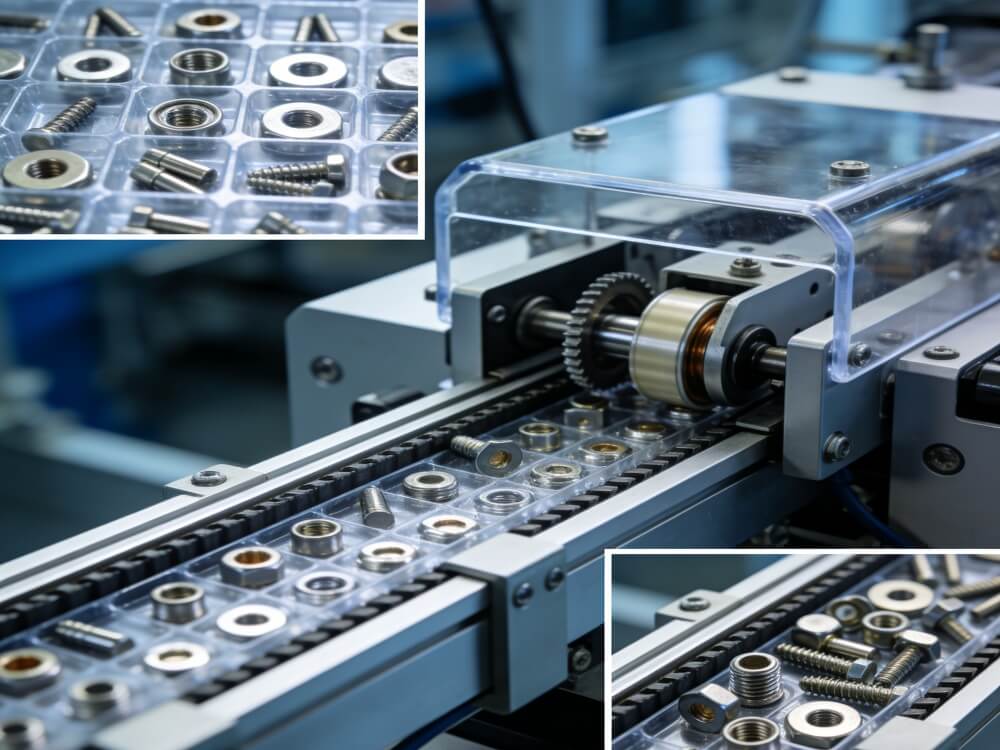

“The biggest bottleneck in hardware packaging is loading odd-shaped items. Our advanced feeding systems are engineered to solve this. Whether you are packaging tiny screws, long drill bits, or heavy wrenches, we customize the feeding mechanism—using vibratory bowls or robotic pick-and-place arms—to match your product’s unique geometry.

This technology ensures precise orientation and placement, eliminating the need for manual labor. It turns the most difficult part of your packaging process into a smooth, fully automated operation.”

Effortlessly sort and feed small, chaotic items. Our custom bowls align screws, wall plugs and nails for high-speed, precise loading, ensuring exact counts in every blister without manual handling

Automate the handling of heavy, irregular tools. Our robotic arms precisely orient and place pliers and wrenches into cavities, ensuring consistent alignment while eliminating the bottleneck of manual loading

Master the complexity of kitting. These versatile feeders handle multiple component types simultaneously, perfect for creating furniture assembly packs or mixed hardware sets with speed and flexibility

“From tiny screws to heavy hammers, if you manufacture it, we can package it. Our machines are versatile enough to handle loose fasteners like nails and bolts with speed, while providing secure, heavy-duty sealing for hand tools like pliers, wrenches, and screwdrivers.

We even master the ‘tricky’ stuff—sharp drill bits, saw blades, and delicate automotive parts like spark plugs. Whether it’s a single item or a complex multi-piece kit, our equipment adapts to your specific product needs.”

“Sharp edges demand tough packaging. Our machines safely handle drill bits and saw blades, creating puncture-resistant blisters that protect cutting teeth. Whether for single blades or complex multi-bit sets, we ensure a secure, heavy-duty seal that withstands shipping and looks professional on retail racks.”

“Heavy tools require heavy-duty protection. Our machines deliver a rock-solid seal for pliers and wrenches, ensuring they stay secure despite their weight. We specialize in anti-theft clamshells and high-visibility blisters that keep your tools locked in place during shipping and attractive on the store display.”

“Say goodbye to manual counting. Our machines master the chaos of fasteners and small parts like screws, bolts, and nails. Featuring custom vibratory bowl feeders, we automate high-speed loading for both single items and mixed hardware kits. You get precise counts, zero errors, and maximum daily output.”

“Delicate ceramics meet high-speed automation. Our machines are tuned to handle spark plugs gently, preventing cracks while maintaining massive output. We support flexible configurations—from single blisters to multi-packs for engine sets. Ensure your auto parts stay moisture-free and showroom-ready with a seal that screams quality.”

Q: Can the machine handle different sizes of hardware?

A: Yes, with quick mold change.

Q: How do you handle heavy tools falling out?

A: We use high-pressure heat sealing.

Q: Do you provide the packaging materials (PVC/Card)?

A: We provide the machine, but can recommend material suppliers.

You can get a price of this model or send us any question to get any information you would like to know, we will reply to you soonest.