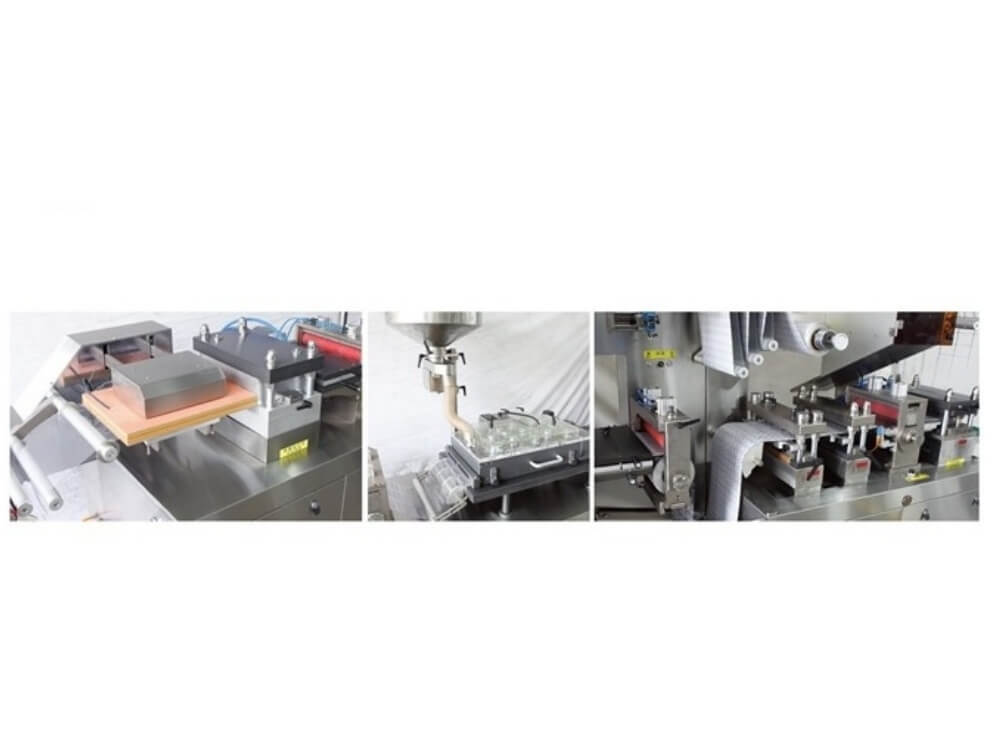

Food blister packaging machines are designed to pack food products such as Chocolate & Candy, Biscuits & Snacks, Butter & Cheese Portions, Honey / Jam / Sauce Cups, Nutritional Supplements, and Instant Food Tablets into sealed blister packs using plastic film and lidding materials.

They ensure hygiene, extended shelf life, and attractive product presentation

for a wide range of food applications.

The food blister packaging machine is suitable for packaging various forms of food, including solids, liquids, and powders.

For solid foods such as chocolate and candies, it can achieve single-chamber independent packaging, with a neat appearance and convenient for retail.

Biscuits and snacks can be independently blister-packed to avoid contamination and maintain hygiene and freshness.

For liquid and semi-liquid products, the equipment supports precise quantitative filling of butter, cheese, honey, jam, and other similar products, ensuring a firm seal and preventing leakage.

At the same time, this food-grade blister packaging machine is also suitable for packaging tablet and capsule nutritional and health products, including automatic forming, filling, and sealing.

By changing the mold and filling system, one food blister packaging machine can meet the packaging needs of various food products, offering flexibility, efficiency, and hygiene.

The blister packaging machine is used for the independent cavity packaging of chocolates and candies, achieving precise shaping and sealing, effectively preventing moisture and adhesion, and enhancing the product hygiene and display effect on the shelves.

The food blister packaging machine is used for single-serve blister packaging of biscuits and snacks. It can prevent moisture and breakage, maintain the freshness and hygiene of the products, and improve the packaging neatness and retail display effect.

The food-grade blister packaging machine is suitable for the quantitative blister packaging of butter and cheese. Aluminum-plastic sealed blisters enable precise filling and sealing, effectively preventing leakage and contamination. It is convenient for storage, transportation, and retail use.

The liquid food blister packaging machine is used for precise quantitative blister packaging of honey and jam. It has strong sealing performance, is leak-proof and anti-contamination, and is suitable for single-use and retail packaging.

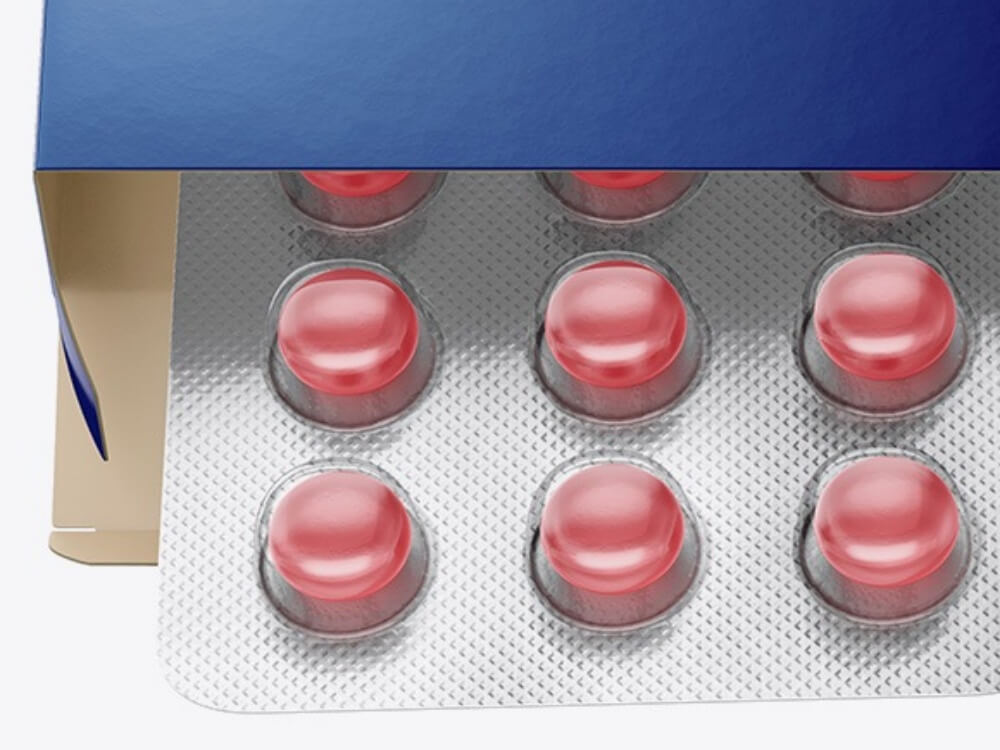

The blister packaging machine is used for blister packs of tablets and capsules of nutritional supplements. It enables individual packaging of each pill, preventing moisture and contamination. It is convenient for measurement, carrying, and compliant sales.

The small blister packing machine is an ideal solution for the small-scale and cost-effective packing of solid foods, suitable for individual cavity packing of candies, chocolates, nuts, biscuits, and other similar products. It emphasizes hygiene, moisture-proofing, and orderly display.

The automated large blister packing machine boasts a higher production capacity and is equipped with a servo drive and a stable sealing system, making it suitable for efficiently packaging expanded snacks, powder products, and other similar items.

The liquid food blister packaging machine supports the filling of liquids such as honey, jam, butter, cheese, etc., providing precise quantification and sealing protection to prevent leakage and contamination.

Different models have their own advantages in terms of automation level, filling methods, and mold configuration, which can meet the diverse packing needs ranging from small batches to high production capacity, from solid foods to liquids, from snacks to nutritional products, helping customers choose the most suitable food blister packing solution for their product form and production scale.

Suitable for small batch food production, Ideal for startup food factories.

Punches Frequency | 25-60times/min |

Production capacity | 6000-14000pcs/hour |

Max. Forming depth | 20mm, customized |

Stroke travel range | 30-120mm, 140mm customized |

Total power supply | 380V 50Hz 8.5kw |

PVC hard film | 0.25-0.5×260 mm |

Dialysis paper | 50-100g×260mm |

PTP Aluminum film | 0.02-0.035×260mm |

Mould cooling | Tap water or recycling water |

Overall dimension | 4460*760*1620mm(L×W×H) |

Weight | 1850kg |

High-speed food blister packing, servo-driven, stable sealing.

Punch frequency | 10-33times/min |

Production capacity | 2400plates/hour |

Max. Forming area & Depth | 105*70* 25mm (As adjusted) |

Standard Stroke range | 30-80mm, customized |

Total power supply | 380V/220V 50Hz 2.8Kw |

PVC hard Film | 0.15-0.5*110 (mm) |

Dialysis Paper | 50-100g*110mm |

PTP Aluminum film | 0.02-0.035*110mm |

Mould cooling | Tap water or Recycling water |

Overall Dimension | 1840*590*1100 mm (L*W*H) |

Weight | 450kg |

Designed for honey, jam, and sauce, precise filling & sealing.

Punch frequency | 10-20times/min |

Production capacity | 1200plates/hour |

Max. Forming area & Depth | 105*70* 25mm (adjusted) |

Standard Stroke range | 30-80mm, customized |

Standard plate size | 80*70mm, customized |

Power supply | 220V 50Hz 2.8Kw |

PVC hard Film | 0.30-0.35*110mm |

PTP Aluminum film | 0.025*110mm |

Dialysis Paper | 50-100g*110(mm) |

Overall Dimension | 1800*590*1050mm (L*W*H) |

Weight | 415kg |

The food is packaged in blister bubbles, mainly to meet your demands for hygiene, safety, and convenience.

Firstly, blister packaging can encapsulate each portion of the food separately, effectively preventing contamination, moisture, and oxidation, and ensuring the freshness and taste of the product.

Secondly, for snacks, candies, chocolates, biscuits, etc., the individual cavity packaging is convenient for distribution and retail, enhancing the display effect on the shelves.

At the same time, for liquid or semi-solid foods such as honey, jam, butter, and cheese, blister packaging enables precise quantitative filling and sealing, preventing leakage and contamination, and facilitating transportation and storage.

Finally, blister packaging also enhances the professionalism and added value of the product, making it more convenient for you to use and carry. In summary, blister packaging not only ensures food safety but also meets customers’ multiple needs for product quality, convenience, and aesthetics.

The food blister pack machine achieves independent cavity sealing, with dust-proof, bacteria-proof, and verifiable sealing capabilities. It effectively prevents tampering and ensures food hygiene and safety.

The food blister packing equipment with Ceramic pump filling can achieve precise and quantitative filling, ensuring that each portion of food or liquid product has the same specifications, reducing waste, and improving packaging efficiency and product quality.

The food blister packaging solutions effectively seals individual compartments to prevent the intrusion of air, moisture and contaminants, thereby extending the shelf life of the food and maintaining its freshness and taste.

The food blister packaging machine can achieve neat and attractive individual cavity packaging, highlighting the shape and color of the product, thereby enhancing the appeal of the shelves and consumers’ purchasing intention.

The packaging design of the food blister packaging machine is convenient for consumers to open, while maintaining sealing and hygiene, thereby enhancing the convenience of use and the user experience.

The food blister packaging machine uses PVC, PET, HIPS, PP, or aluminum foil and other forming materials that meet food-grade standards.

This ensures that there is no toxicity or pollution when in direct contact with food, and it complies with international food safety regulations. The equipment design emphasizes hygiene. The forming, filling, and sealing processes are fully enclosed to reduce contact with air and microorganisms, preventing cross-contamination.

For solid, liquid, and powder foods, the selection of materials and sealing methods ensures the preservation, moisture-proofing, and leak-proofing of the products, while meeting consumers’ demands for safe and hygienic packaging.

Through reasonable material combinations and strict process control, customers can confidently package candies, chocolates, biscuits, pastes, or liquid foods, achieving dual guarantees of food safety and quality.

The food blister packaging machine uses non-toxic PVC / PET / PP forming film to ensure safety when in direct contact with food, preventing contamination and the migration of harmful substances, thereby safeguarding the health of consumers and the quality of the products.

The food blister packaging machine uses food-grade & compliant materials that can come into direct contact with food, ensuring the safety and cleanliness of the packaging, compliance with food hygiene standards, and preservation of the freshness and quality of the products.

The food blister packaging machine can be equipped with environmentally friendly materials, such as aluminum foil, to reduce the impact on the environment. At the same time, it is safe and hygienic, meeting the requirements of sustainable development and green packaging.

Our food blister packaging machine is specially designed for various food forms, including solid candies, chocolates, biscuits, crispy snacks, as well as liquid products such as honey, jam, butter, and cheese. The equipment supports precise quantitative filling and independent cavity packaging, ensuring product hygiene, moisture-proofing, anti-pollution, and extending shelf life.

Different models cover small batch, low-cost to high capacity automation needs, providing flexible molds and feeding configurations to meet customers’ diverse requirements for production volume and product types.

Using food-grade, safe, and environmentally friendly materials, the packaging is reliable and verifiable, enhancing product safety and consumer trust.

Whether for retail display, aesthetics, or ease of operation, our machines balance efficiency, quality, and cost, allowing customers to easily choose the blister packaging solution that best suits their business.

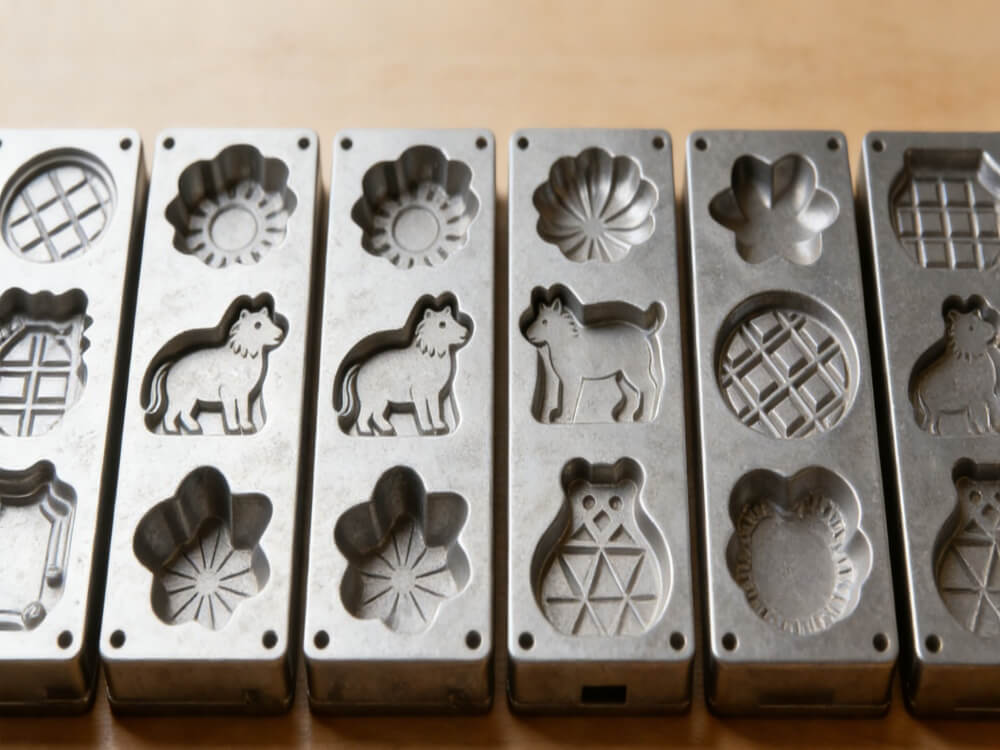

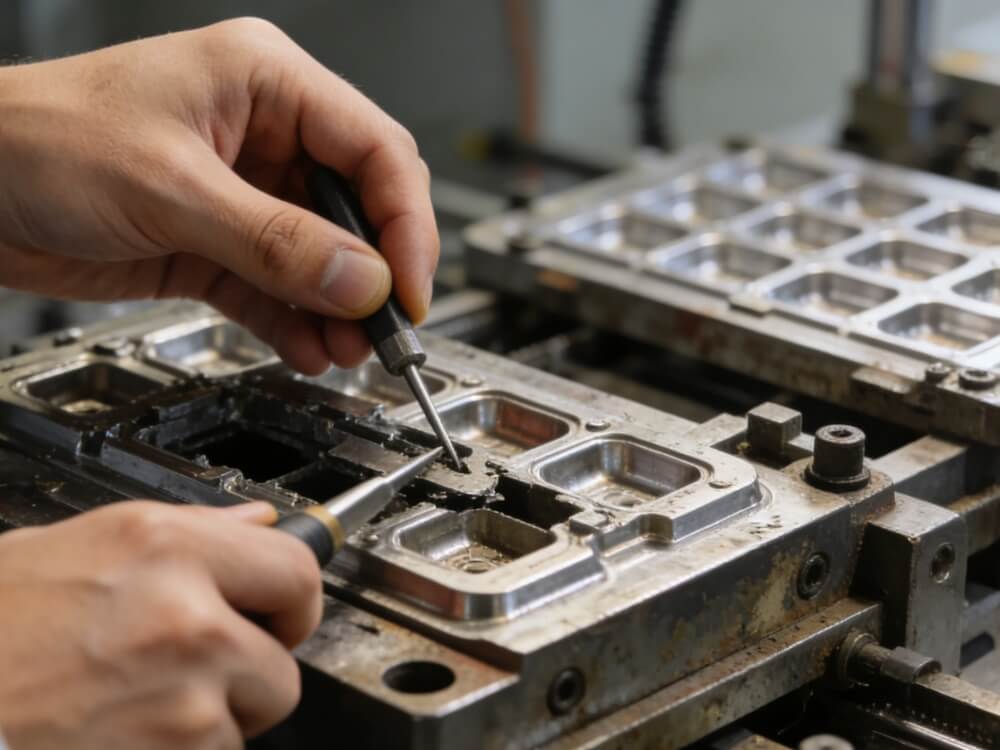

Provide custom food molds that can be designed according to different shapes, such as chocolate, candies, and cookies. This ensures precise and aesthetically pleasing packaging, while also enhancing production efficiency and product value.

The blister packaging machine ensures stable forming and sealing quality, ensuring that each cavity is securely sealed, leak-proof, and free from contamination, thereby enhancing food safety and packaging consistency.

The machine supports rapid mold replacement, enabling it to easily adapt to different food shapes and specifications, achieving diversified packaging and enhancing production flexibility and efficiency.

Provide global services and technical support to ensure the smooth installation, debugging, and maintenance of customer equipment, respond promptly to issues, and guarantee the continuity and long-term stable operation of production.

Q: What food products can be blister-packed?

A: Suitable for packaging various forms of food, including solids, liquids, and powders.

Q: Is blister packaging safe for food?

A: Yes, the machine material uses 304 food-grade stainless steel, and the packing film is non-toxic.

Q: Can the machine handle liquid food?

A: Yes, the machine is running well with liquid products as jam, honey, oil, butter, and sauce, etc.

Q: What is the production capacity?

A: We develop different models for different capacities required. Please contact us for details.

Q: Can molds be customized?

A: Molds are customized according to your product size & shape.

Q: What are the payment terms?

A: We accept TT, LC payments.

Q: How about the lead time?

A: Usually standard machine takes about 30 days. Customized needs 35-40 days after mold drawings are confirmed.

You can get a price of this model or send us any question to get any information you would like to know, we will reply to you soonest.