Cosmetics require not only protection, but also visual appeal.

Our cosmetic packaging machines are designed to deliver clean sealing, precise forming, and premium presentation for skincare, makeup, and personal care products.

From small batches to mass production, we provide customized cosmetic packaging solutions.

Blister packaging machines are widely used in the cosmetics industry and are suitable for products with high requirements for appearance, hygiene, and protection. Common types of cosmetics packaging include: lipsticks, lip balms, powder compacts, eye shadows, makeup brushes, masks, eye masks, small ampoules of essence liquids, trial packs, and travel-sized cosmetics etc.

This facial cream and facial gel are packaged in blister packs. This packaging method enables a one-time seal, ensuring both hygiene and safety, while also preventing contamination. The sealing effect is excellent, preventing moisture absorption and oxidation, and maintaining the stability of the product.

The transparent blister packaging has an outstanding display effect, enhancing the brand image, and is suitable for trial packs and travel packs, making it convenient for carrying and selling.

Lipsticks and lip balms are packaged in blister packs. This packaging method can firmly secure the products, preventing deformation and scratches. The transparent blister can showcase the appearance of the products, enhancing the appeal of the shelves.

The individual sealing ensures hygiene and dust prevention, making it suitable for retail display and promotional packaging.

These face masks and eye masks are packaged in blister form, which enables independent sealing to prevent moisture and contamination, and maintain the stability of the essence liquid.

The packaging is flat and attractive, making it convenient for display and transportation. Each product is placed separately in a compartment, which is easy to use and suitable for retail and promotional purposes.

The serum and ampoules are packaged in blister form. This packaging method enables single-dose sealing, prevents oxidation and contamination, and maintains the stability of the active ingredients. The dosage is precise, making it convenient to carry and use.

The appearance is professional and upscale, suitable for packaging medical aesthetics and high-end skincare products.

Cosmetic tools and accessories are packaged in blister form. This packaging method can firmly secure the products, preventing scratches and squeezes. The transparent display structure and detailed design enhance the attractiveness of the shelves.

This packaging is sturdy and durable, suitable for retail display, theft prevention, and transportation protection.

The samples and trial-sized cosmetics are packaged in blister trays, which allow for independent sealing with each use. This packaging is both hygienic and safe, preventing leakage and contamination.

Lightweight with an excellent display effect, which is convenient for promotional distribution and retail display, and can effectively reduce costs and increase the conversion rate of trial products.

In the cosmetics industry, different products require corresponding packaging forms and equipment. Blister packaging is suitable for lipsticks, essence bottles, facial masks, and trial packs, enabling independent sealing and providing a good display effect.

Tray + lid packaging is suitable for face creams, facial mask sets, and combined products, facilitating neat placement and transportation.

Paper-plastic blister packaging is often used for small cosmetic products and promotional packaging, balancing display effect with environmental friendliness.

Sample blister packaging is specifically used for trial and experience packs, featuring precise dosage and convenient portability.

For different packaging forms, suitable blister packaging machines or thermoforming packaging machines can be selected for integrated production of forming, sealing, and punching. By choosing the appropriate packaging type and equipment, not only can the safety and hygiene of the products be ensured, but also the appearance quality and market competitiveness can be enhanced.

Cosmetic blister packaging can be made of PVC, PET, or PP blister sheets, and sealed together with paper cards or aluminum foil. It is suitable for skincare products, cosmetics and trial samples.

This packaging has excellent sealing performance and outstanding display effect. It supports customization of various specifications to meet the needs of retail display and brand promotion.

The cosmetic tray with a lid packaging can achieve a stable arrangement and overall protection, suitable for face creams, masks, and set products.

The packaging is resistant to pressure, moisture and is elegant and stylish, facilitating transportation, display, and brand promotion. It also supports automated production and multi-specification customization.

The paper-plastic blister packaging combines paper card support with a plastic blister, suitable for small cosmetic items and trial packs.

The packaging is beautiful, lightweight, sealed, and dust-proof, convenient for retail display and promotional distribution. It also supports customization in various sizes and is made of eco-friendly materials.

The blister packaging of cosmetic samples can achieve independent sealing each time they are used separately, preventing moisture and contamination, and maintaining the product’s activity.

This packaging is lightweight, attractive, and convenient for promotional distribution and retail display. At the same time, it supports multi-size customization and brand printing, thereby increasing the conversion rate of trial products.

The key requirements for cosmetic packaging include: hygiene and safety to prevent contamination of the product; good sealing to prevent moisture and oxidation, maintaining the stability of the product; compatibility of materials, suitable for various textures such as skincare products and makeup; precise dosage for convenient single-use by consumers; aesthetic presentation to enhance brand image and shelf appeal.

Ease of transportation and display, resistant to compression and damage; customization and flexibility to meet different specifications, promotions and trial packs; compatibility with automated production to support efficient large-scale manufacturing. These requirements ensure that cosmetic packaging is both safe and reliable, and also has market competitiveness.

The blister packaging machine can achieve high transparency and precise shaping, perfectly presenting the appearance of cosmetics; the edges are smooth and aesthetically pleasing, enhancing the product’s grade and the attractiveness of the shelf, while ensuring the packaging is stable, dust-proof, and resistant to deformation.

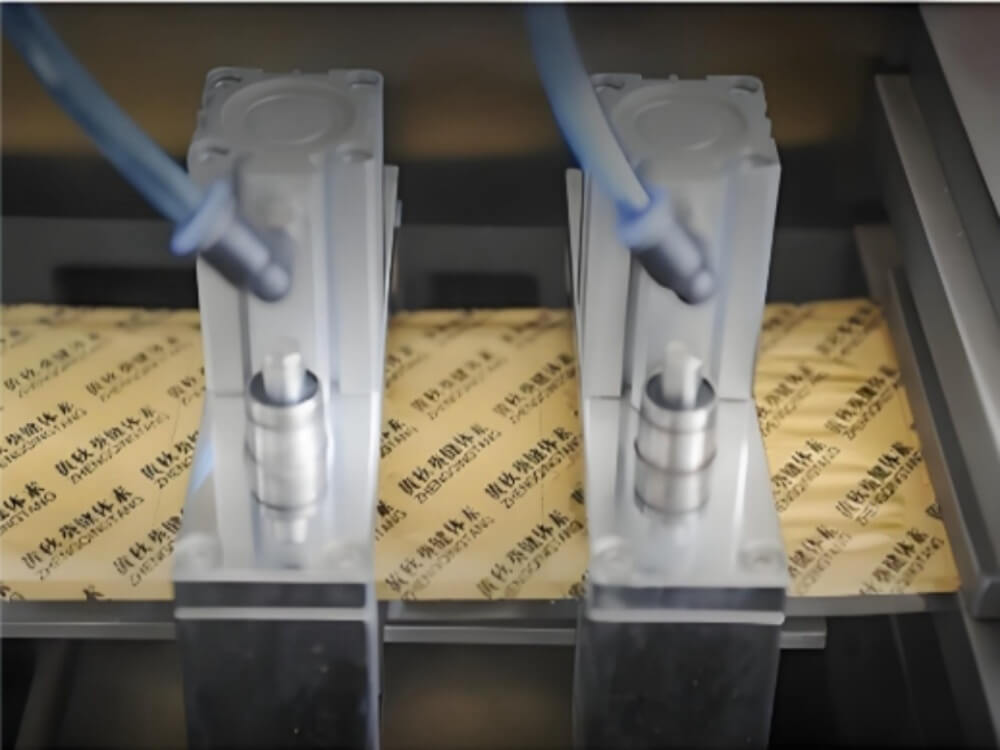

The blister packaging machine can achieve a smooth and flat seal, ensuring a tight and leak-proof seal, as well as preventing contamination. At the same time, it enhances production stability and packaging aesthetics, thereby improving the quality of cosmetics and enhancing consumer trust.

The blister packaging machine can achieve fully enclosed and automated packaging, reducing manual contact and ensuring product hygiene and safety; at the same time, it is dust-proof and pollution-proof, suitable for high-standard cosmetic production and efficient large-scale manufacturing.

The blister packaging machine can ensure that the cavity depth and shape are consistent, guaranteeing the stability and accuracy of each cosmetic package; it improves production stability and appearance consistency, and enhances product quality and brand image.

The blister packaging machine is compatible with various cosmetic-grade materials (such as PVC, PET, PP, etc.), ensuring safety and no pollution. It can adapt to different product characteristics, achieve stable shaping, and enhance packaging quality and brand image.

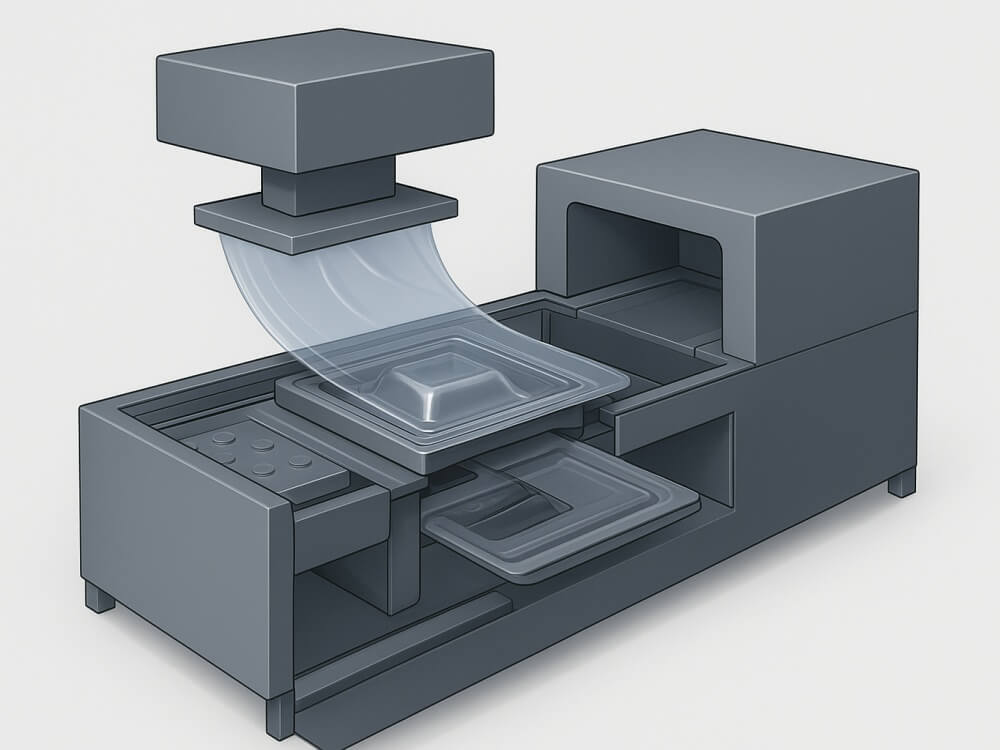

By choosing our cosmetic blister packaging machine, you will enjoy an efficient and professional production process, along with the advantages brought by various functions. This machine adopts an integrated process of automatic film feeding, heating molding, product loading, sealing, and punching, ensuring precise and stable performance at every step.

The hot forming or cold forming technology can achieve consistent cavity depth and precise shape, suitable for various products such as creams, lipsticks, essence bottles, and masks. The sealing system ensures smooth and tight sealing, preventing moisture and contamination, and maintaining product quality.

This equipment is compatible with cosmetic-grade materials such as polyvinyl chloride, polyethylene terephthalate, and polypropylene, supporting rapid mold replacement and multi-specification production, meeting the needs of trial packaging, retail packaging, and sets.

Fully automatic or semi-automatic operation reduces manual contact, ensuring hygiene and safety. The entire process is efficient and stable, not only improving production efficiency but also ensuring attractive packaging and enhancing the market competitiveness of the products.

The blister packaging machine can achieve precise shaping, ensuring consistent cavity shapes, perfectly securing cosmetics, presenting a refined and beautiful appearance, and enhancing the product’s grade and shelf appeal.

The blister packaging machine can achieve stable sealing without deformation, ensuring a tight and leak-proof seal, preventing contamination, while maintaining a flat and attractive packaging, thereby enhancing product quality and consumer trust.

Equipped with a servo drive system, which operates smoothly and precisely, improving production efficiency, reducing malfunctions and product damage, ensuring a continuous and stable packaging process, and uniform finished products.

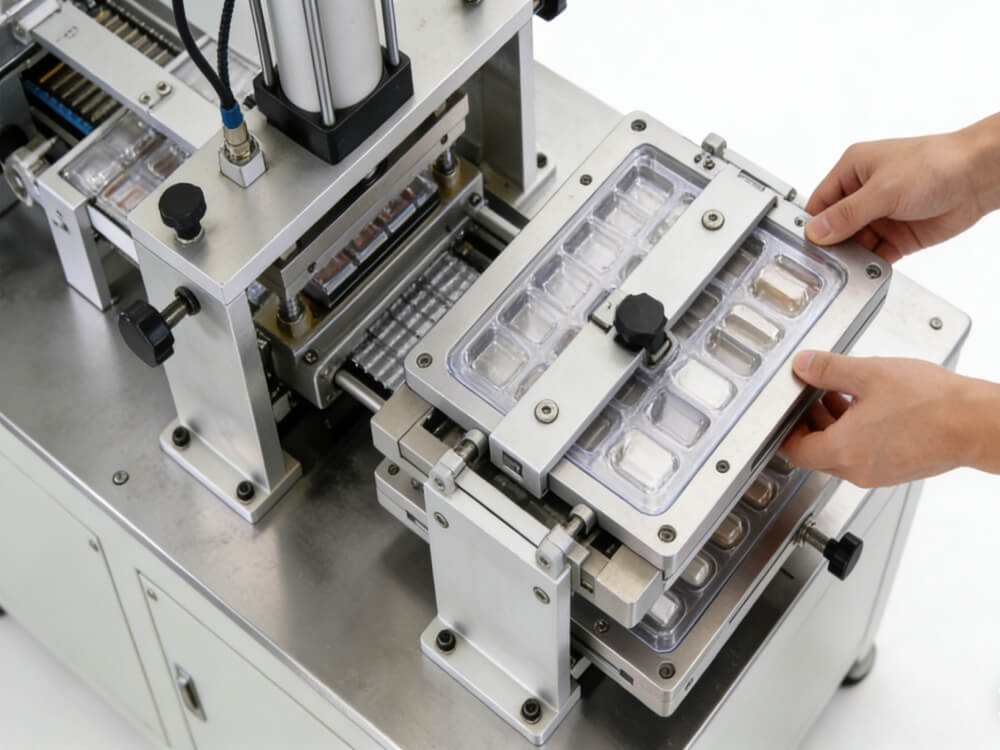

The blister packaging machine supports rapid mold change, allowing for easy switching between various cosmetic specifications, reducing downtime, and enhancing production flexibility. It meets the diverse SKU requirements and boosts production efficiency.

The blister packaging machine is equipped with a customized feeding system, which can accommodate different shapes and specifications of cosmetics, ensuring precise product loading, enhancing production efficiency and reducing waste.

Suitable for manual, semi-automatic, and fully automatic production lines. It can flexibly meet different production volume requirements, improve efficiency, reduce labor costs, and support diverse cosmetic packaging solutions.

To meet the diverse market demands of the cosmetics and other industries, the blister packaging machine has been designed in various models.

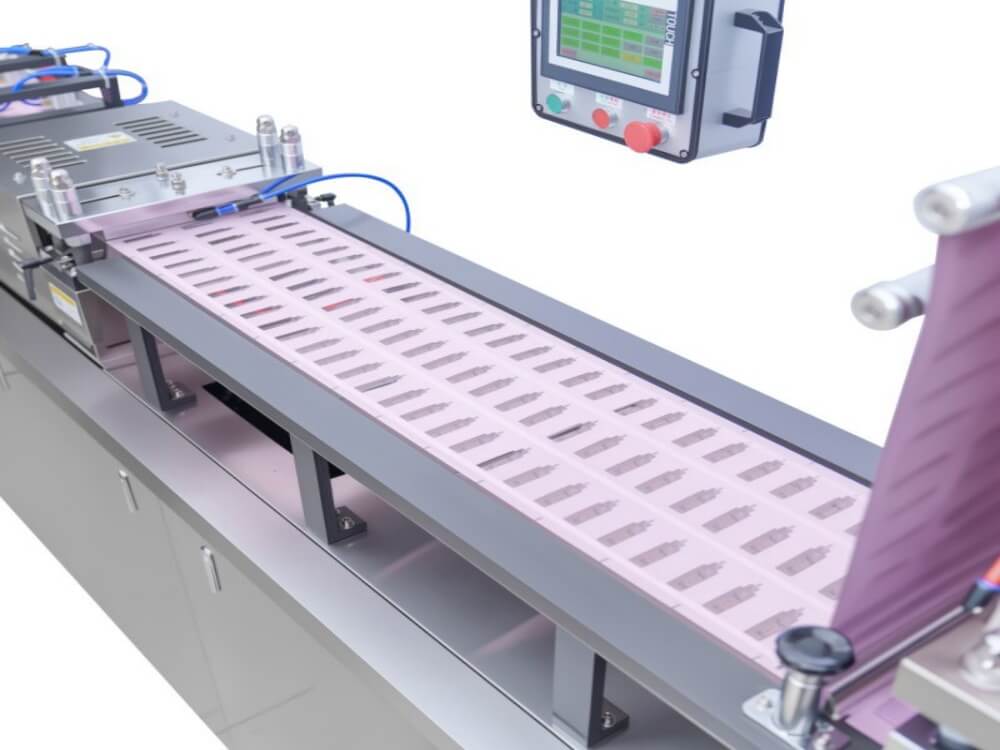

The small-sized model is suitable for trial production and small-scale manufacturing, featuring flexible operation and a small footprint; the medium-sized model caters to medium production volumes and regular product packaging, balancing efficiency and stability; the large-scale, fully automatic model is suitable for large-scale, high-speed production, supporting rapid mold change for multiple specifications and enhancing production flexibility and efficiency.

Different models can meet the production volume, product specifications, and automation level of different customers’ requirements, and achieve multi-level market services.

This small cosmetic blister packaging machine is used to pack small cosmetics and trial packaging, flexible and convenient

Medium-sized output, suitable for regular products such as face creams and lipsticks.

High-yield fully automatic production line, suitable for large-scale production of masks, essence bottles, etc.

Are you looking for the right cosmetic packaging machine?

Tell us:

You will get a Customized Cosmetic Packaging Solution soon.

You can get a price of this model or send us any question to get any information you would like to know, we will reply to you soonest.