Blistering packaging machines are essential equipment for securely packing tablets, capsules, softgels, medical devices, foods, cosmetics, and various hardware components. As a professional manufacturer, We explore our full range of thermoforming and cold-forming blister packaging machines designed for different production scales—from small batches to mass-production lines.

Our blistering packaging machines offer stable forming, precise sealing, flexible feeding systems, and high production efficiency, ensuring reliable blister packaging performance in demanding industrial environments.

Our Blistering packaging machines are widely used for pharmaceuticals, nutraceuticals, food, cosmetics, and industrial components. There are different models as per capacity & products required.

DPP 80 blister packaging equipment, DPP 150 blistering packaging machine, DPP 250 alu-alu blister machine, DPP 350 thermoforming blister machine, BH-350A PP Blister Packaging Machine etc. They provide accurate forming, safe sealing, and high production efficiency.

Our full range covers PVC/PET/PE/ PVDC/PP thermoforming models and alu-alu cold forming machines for moisture-sensitive products.

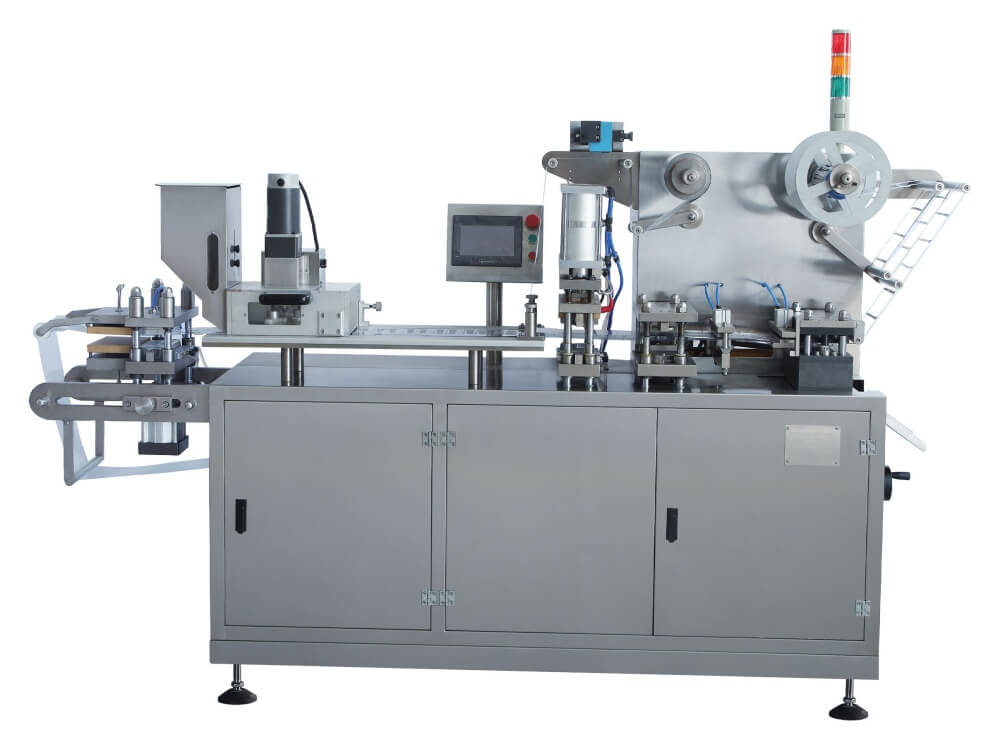

A compact device for laboratories, R & D centers and small volume production. Small footprint, easy to operate. Suitable for tablets, capsules, small sweets, and sample sets. Die change quick design. Ideal for start-up production and market testing.

Punch frequency | 10-33times/min |

Production capacity | 2400 blisters/hour |

Max. Forming area & Depth | 105*70(standard depth ≦12mm), Max. Depth 25mm (As adjusted) |

Standard Stroke range | 30-80mm (can be designed as per user’s required) |

Standard plate size | 80*70mm(can be designed as per user’s required) |

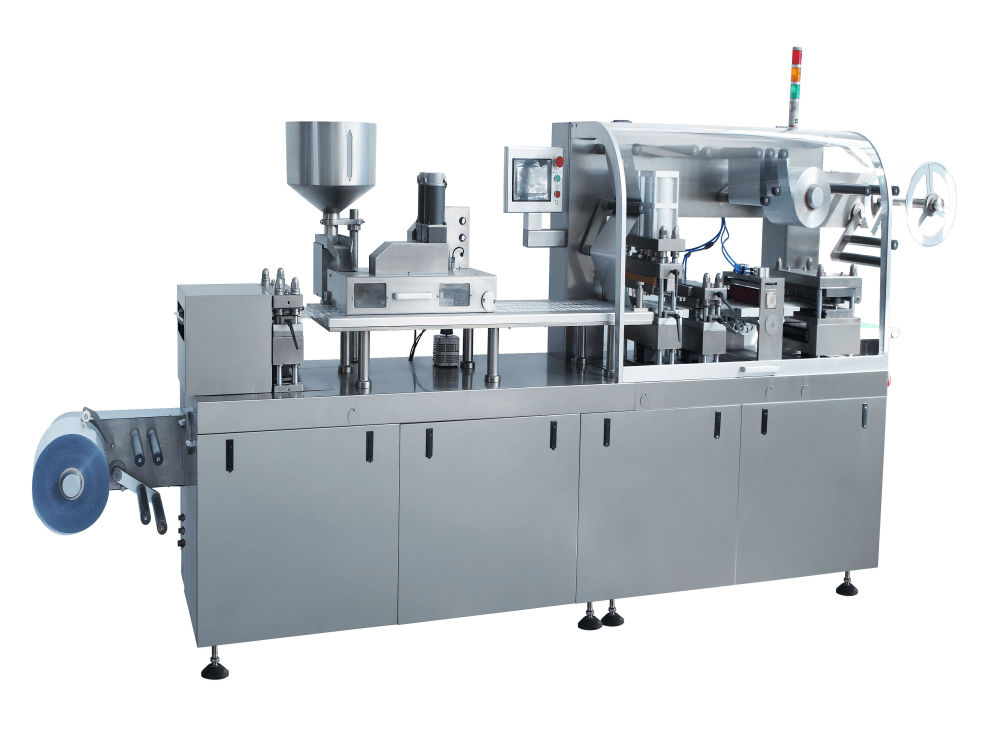

Designed for small-scale commercial production. Higher output compared to mini models. Stable heating and forming performance. Widely used in nutraceutical and small-pharmaceutical workshops.

Technical Specifications:

Punches Frequency | 15-35times/min |

Max. Forming area | 140*100mm |

Max. Forming depth | 16mm |

Stroke travel range | 40-120mm, adjustable |

A versatile model for medium-to-large production volumes. Compatible with PVC/PET and alu-forming materials. Optional vibratory feeder, brush feeder, guide-rail feeder. Very stable sealing performance for pharma packaging. Perfect for high-speed capsule and tablet blistering.

Technical Specifications:

Punches Frequency | 25-60times/min |

Production capacity | 6000-14000pcs/hour |

Max. Forming depth | 20mm, customized |

Stroke travel range | 30-120mm, 140mm customized |

A professional solution for pharmaceutical factories. Servo driving system for precise motion control. High forming depth and consistent sealing. Automatic detection, waste cutting, batch code printer.Suitable for a wide range of blister formats

Technical Specifications:

Punches Frequency | 25-60times/min |

Production capacity | 6000-14000pcs/hour |

Max. Forming depth | 20mm, customized |

Stroke travel range | 30-120mm, 140mm customized |

Designed for products moisture-sensitive or light-sensitive. Use aluminum/aluminum cold forming material. Provide maximum protective barrier. The molding depth is larger, and the cavity is durable.

Technical Specifications:

Punches Frequency | 20-30times/min |

Production capacity | 4800-7000pcs/hour |

Max. Forming depth | 18mm, customized |

Stroke travel range | 30-110mm, customized |

Widely used in PET /PVC/HIPS, GPPS and other plastic blister,food/hardware/daily use/medicine/electronic components/health care products and similar materials for blister sealing packaging.

Technical Specifications:

Punches Frequency | 12-25cycle/min |

Material | PVC PET HIPS PLA |

Max. Forming are | 330*240mm (L*W) |

Max. Forming depth | 46mm |

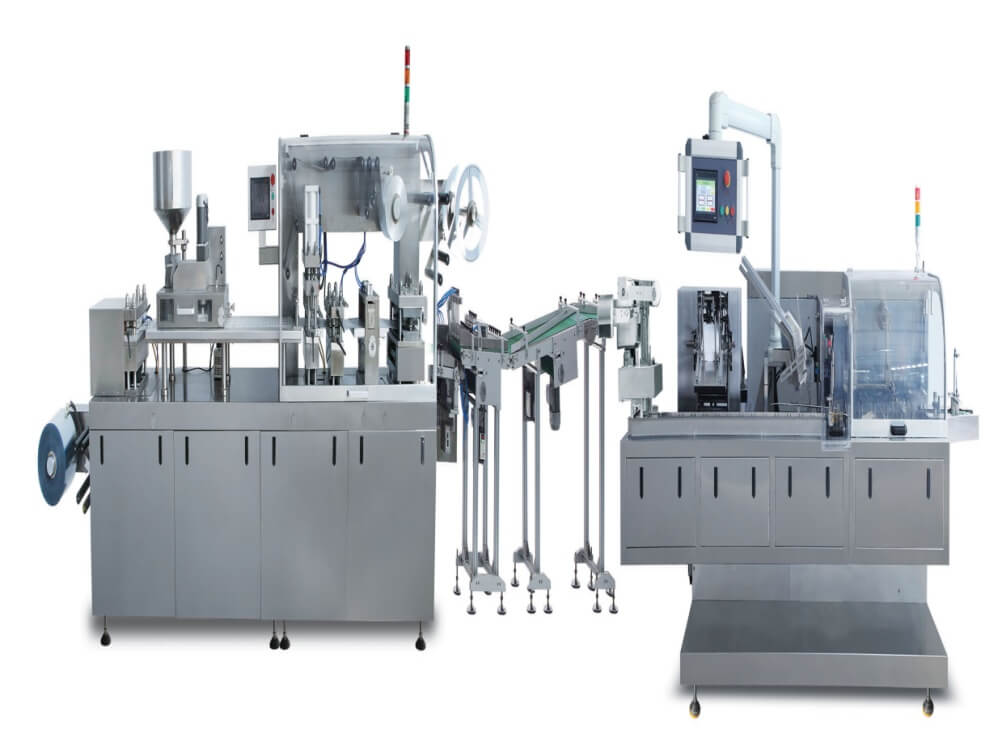

Integrated blister forming, sealing, punching and cartoning. Automation of the whole line. High production is suitable for large pharmaceutical enterprises. Reduce labor costs and prevent cross contamination.

Technical Specifications:

Punches Frequency | Al/pvc: 25-60times/min, Al/Al 20-35times/min |

Production Capacity | Al/pvc:6,000-14,000blister/hour, Al/Al: 4,800-7,200blister/hour |

Max. Forming depth | Al/pvc: 20mm, Al/Al: 18mm, customized |

Carton Dimension Requirement | (60-180)*(20-80)*(15-70)mm |

Carton Quality Requirement | 250-450g/㎡ according to carton size |

Our automatic blistering packaging machine with xcellent product protection, packaging materials wide compatibility, multiple industries suitable, fast and easy changeover, attractive packaging appearance, safe operation & easy maintenance and multiple inspection options functions.

Controlled heating area, uniform PVC softening, stable molding results to ensure consistent cavity shape.

Brush feeder, Vibratory feeder, Guide-rail feeder. This ensures that products such as tablets, capsules, hardware components, candies or irregular items are placed in the correct position.

Constant-temperature sealing, optional servo seal pressure control, ensures airtight, durable blister packs.

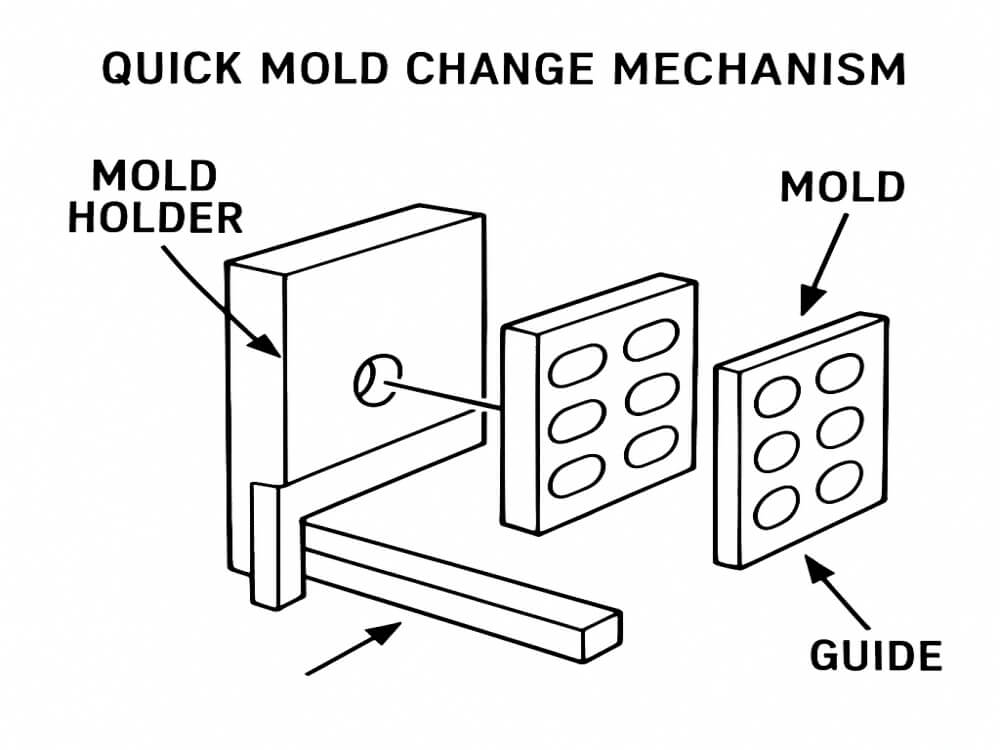

The ability to quickly switch between different types of packaging and minimize downtime makes it ideal for a variety of production environments.

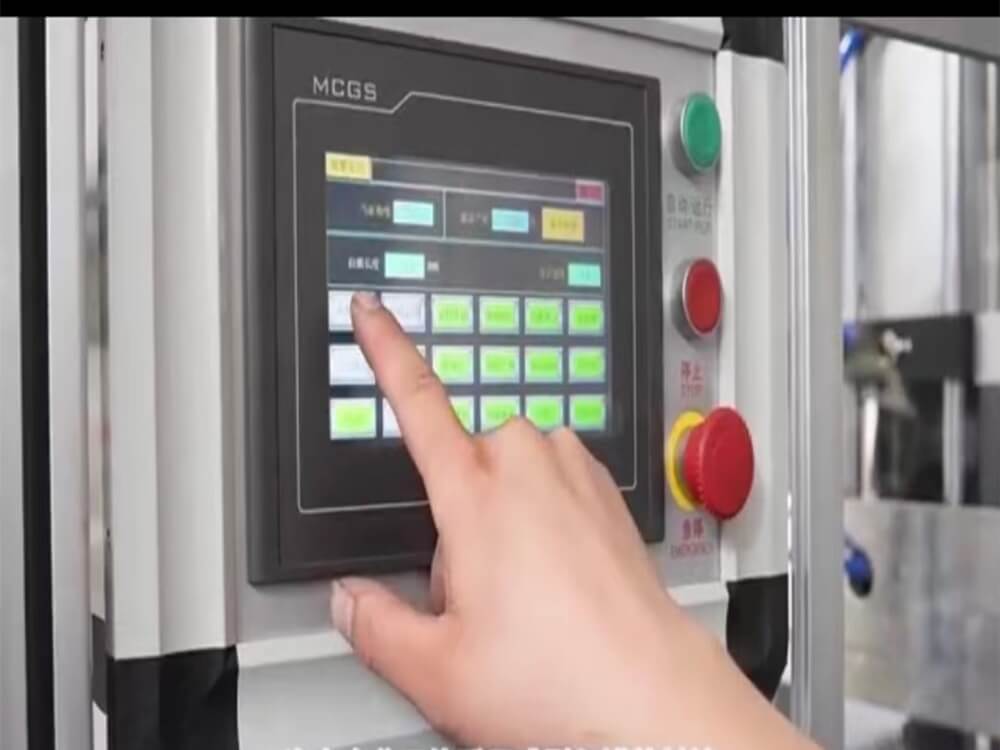

Touch screen HMI, PLC control and automatic detection of missing labels, film breakage and seal temperature deviation.

Blister packaging is widely used in many industries. Such as the pharmaceutical industry of tablets, capsules, suppository packaging. Food industry candy, liquid packaging. Cosmetic sample packaging. Small electronics, accessories packaging, etc.

Tablet blister packaging, Capsule blister packing, Softgel blister sealing, Cold-forming for high-barrier drugs.

Vitamin blister packs, Gummy and soft capsules, Small functional foods.

Tiny chocolates, Mints, Single-portion snacks.

Sample kits, Ampoules, Beauty tools.

Batteries, Screws, blades, fittings, Tools and spare parts.

Solid Household Chemical Blocks, Mosquito-repellent Tablets, Air Freshener Blocks.

Model | Stroke Range | Max. Forming Depth (mm) | Speed (Cycles/min) | Materials | Feeding Options |

DPP-80 | 30-80mm (can be designed as per user’s required) | 12–15 | 20–35 | PVC/PET | Brush, Vibratory |

DPP-150 | 40-120mm, adjustable | 16 | 25–45 | PVC/PET | Brush |

DPP-250 | 30-120mm, 140mm customized | 18–22 | 30–60 | PVC/PET/ALU | Brush, Guide-rail |

DPP-350 | 30-120mm, 140mm customized | 22 | 35–70 | PVC/PET/ALU | Multiple options |

18+ years Manufacturing Experience.

Full in-house Machining and Mold Development.

CE/ISO Certificates Compliant.

Fast Delivery and 24/7 Technical Support.

Q1: What materials can a blistering packaging machine run?

PVC, PET, PS, Alu-Alu cold-forming material, and composite foils.

Q2: What is the difference between thermoforming and cold forming?

Thermoforming uses heat to shape PVC; cold forming presses ALU material without heating and provides higher barrier protection.

Q3: Can the machine handle different tablet sizes?

Yes. Molds can be customized according to product shape and blister layout.

Q4: How do I choose the right model?

Selection depends on production speed, forming depth, product type, and packaging material.

You can get a price of this model or send us any question to get any information you would like to know, we will reply to you soonest.