Comprehensive blister packaging solutions for all industries. YABO provide professional blister packaging solutions for the pharmaceutical to nutraceuticals, cosmetics and food industries.

From small-scale R & D to full-scale production, YABO as your supplier of comprehensive blister packaging solutions, we provide you with reliable blister packaging machines for capsule, tablet, cosmetic and food packaging.

Explore our DPP series blister packaging machine, using PVC and aluminum aluminum molding technology for precision, flexibility and reliability.

Blister packaging is a sealing process that encapsulates a product, such as a capsule, tablet, or consumer products, between a thermoformed plastic cavity and a sealing foil.

This packaging provides excellent protection from moisture & contamination; convenience per unit dose; making it an ideal solution for pharmaceutical, cosmetic and food products.

Blister packaging is used in many industries because it keeps products safe, clean, and easy to use. In the pharmaceutical industry, it protects capsules and tablets from moisture and contamination. For nutritional supplements, it helps display vitamins and softgels clearly while keeping each dose separate. In the cosmetic field, blister packs give small items like ampoules or cream samples a clean, attractive look. In the food industry, they’re used for items such as chewing gum or coffee capsules to maintain freshness. Even in industrial fields, blister packaging protects small parts like batteries or tools from dust and damage.

YABO blister packing machines are designed to meet all these needs — offering reliable sealing, easy operation, and flexible customization for different materials and product shapes.

Applications:

In the pharmaceutical and health care products industry, there are generally capsules, tablets, pills, big honey pills. These products can be packaged with a blister packaging machine to achieve.

Pain Points:

We provide you with GMP-compliant, moisture-proof, pollution-proof blister packaging solutions.

Solution:

DPP-80 / DPP-150 models are particularly suitable for laboratory and small-batch production. Such as a product with a large number of test molds for use in experimental or small batch production or as a sample, if your company like this, these two models are well-suited for your development needs.

DPP-260 / DPP-350 for high-speed mass production with precise sealing temperature control. These are suitable for large-scale production pharmaceutical factories and health supplement factories, which will significantly increase production capacity and reduce unit output costs.

Applications:

Blister packaging is widely used for softgels, vitamins, herbal capsules, and dietary supplements. It keeps each dose sealed, clean, and easy to carry, which is perfect for daily health products.

Pain Points:

Many supplement brands produce multiple capsule sizes and small batches. They need packaging that looks professional, protects the product from humidity, and can switch quickly between different molds and materials.

Solution:

YABO blister packing machines, such as the DPP-150 offer quick mold changes system, adjustable forming sizes, and support for both PVC/PET and Alu foil materials. This flexibility helps manufacturers pack various supplement products efficiently while maintaining a clean, attractive appearance.

Applications:

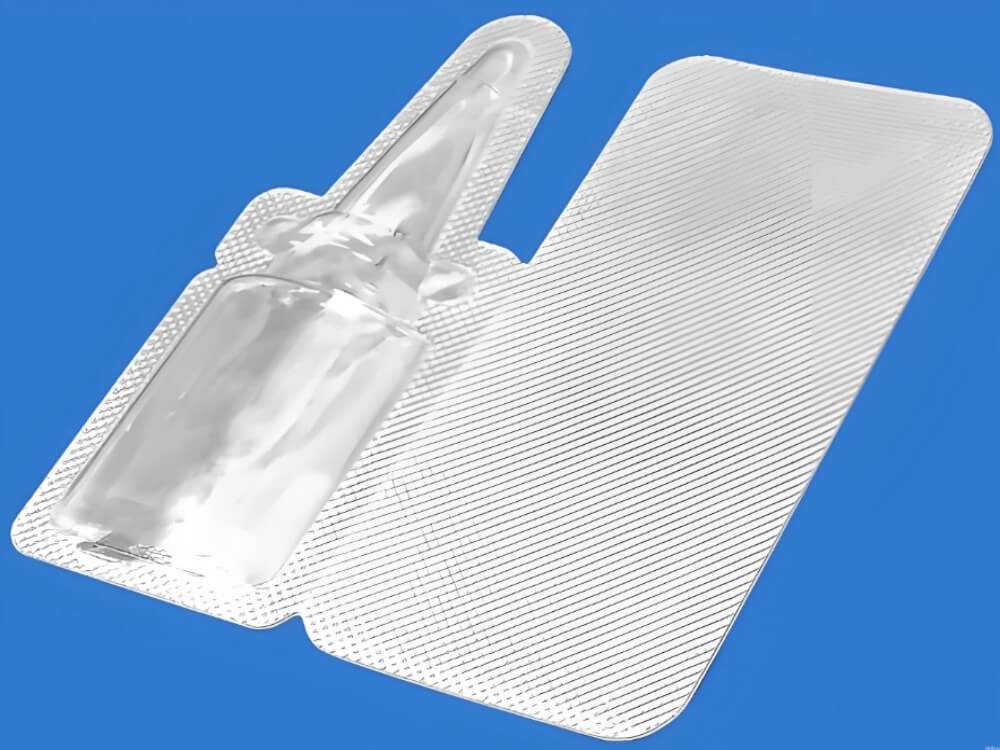

Blister packaging is often used for small cosmetic and skincare products such as ampoules, cream sample packs, face masks, and single-dose treatments. It helps keep products hygienic, easy to use, and visually appealing on shelves.

Pain Points:

Cosmetic brands need packaging that looks premium and clean while protecting sensitive formulas from contamination. They also require flexible shapes and transparent materials to show the product’s color and texture.

Solution:

YABO transparent blister packing machines can form custom cavity shapes using PET or PVC materials to achieve a clear and high-end appearance. With precise temperature control and optional vision inspection systems, our machines ensure every blister pack is well-sealed, hygienic, and high-quality — ideal for beauty and personal care products.

Applications:

Blister packaging is used for many small food items such as chewing gum, chocolate pieces, candies, and coffee capsules. It keeps each piece fresh, clean, and easy to handle while improving shelf appearance.

Pain Points:

Food producers need packaging that is safe, hygienic, and made with food-grade materials. They also need accurate filling and sealing to keep products fresh and prevent contamination.

Solution:

YABO blister packing machines, like the DPP-80 and DPP-150, use stainless steel structures and food-grade materials to meet hygiene standards. The machines provide precise forming and sealing, support for different product sizes and feeder options, making them perfect for packing small food and candy products quickly and safely.

Applications:

Blister packaging is used for small industrial products such as batteries, fuses, screws, tools, and electronic parts. It helps organize items neatly, protects them from dust and scratches, and makes them easy to display and transport.

Pain Points:

Your customers require anti-dust, anti-scratch and strong durable packaging, that can protect heavy or sharp parts. This packaging that looks professional and allows customers to see the product clearly.

Solution:

YABO Alu-Alu cold forming blister machines provide tough, protective packaging for industrial parts. The machines can create custom cavity shapes and deep pockets to fit different components, ensuring each item is safely sealed and well-presented.

Choosing YABO means working with a trusted manufacturer that understands your packaging needs. YABO delivers dependable solutions for both standard and customized needs.With over 18 years of experience, we design and build reliable blister packing machines for different industries, from pharmaceuticals to food and cosmetics.

Our machines are easy to operate, durable, and flexible. They support different materials like PVC, PET, and Alu foil, and can be customized for various product shapes and sizes.

We focus on precision, safety, and efficiency — helping you improve production speed, reduce waste, and deliver clean, attractive blister packs every time.

YABO also provides professional after-sales support, fast spare parts service, and OEM customization to match your production goals perfectly.

Model | Forming Type | Application | Speed (blisters/min) | Feeding Options |

DPP-80 | PVC/Alu | R&D, lab scale | 20–30 | Brush, vibration |

DPP-150 | PVC/Alu | Small batch | 30–45 | Brush, rail |

DPP-260 | PVC/Alu | Pharma production | 40–60 | Vibration, rail |

DPP-350 | Alu-Alu | High speed | 60–80 | Custom feeders |

You can get a price of this model or send us any question to get any information you would like to know, we will reply to you soonest.