The fully automatic PP blister packaging machine is a dedicated equipment for composite sealing packaging. It combines product and packaging personalization, completing blister forming, filling, film covering, heat sealing, punching, and continuous production in one step, significantly reducing labor costs.

It meets the requirements of pasteurization, high-temperature sterilization at 62-65℃ for 20 minutes or 75-90℃ for 15 seconds, as well as low-temperature refrigeration, without deformation or cracking, and with full products.

The PP Blister Packing Machine is a high-performance solution for PP blister packaging, PP clamshell production, and plastic blister sealing. Designed for consistent forming accuracy and long-term stability, this machine supports a wide range of PP sheet materials for medical, food, electronics, hardware, and consumer products.

The packaging materials used are PP, PVS, PET, HIPS, etc. sheets. They are widely applied in the vacuum sealing packaging of liquids, sauces, small particle chili pastes, beauty products, health supplements, daily necessities and similar materials. The products are packaged in a blister style with a tight seal, without leakage, easy to tear, beautiful, and suitable for the packaging production of large quantities of products. Customized molds can be made according to the desired shape of the customer to reflect product diversity and meet the shape requirements of different customers for packaging products.

In medical, healthcare can pack herb, supplement tablets, capsules, pills, medical device thermoformed packaging

In food, to pack candy, chocolate, snacks, liquid products, such as butter, honey, oil, ketchup to keep the food fresh and easy for take.

PP blister clamshells for small electronics, battery blister packs, cosmetic blister packaging to improve looking, more attractive.

Multi-cavity blister for tools, PP thermoformed fastener packaging make hard tools more safe and avoide hurt.

Widely used in PP, PET, HIPS and other plastic blister materials in food, hardware, daily use, medicine, electronic components and health care products fields. Machine running speed based on products size, shape and blister sizes required.

When used for automatic filling of food, cosmetics, liquids, sauces, small particle hot sauces, etc.

Used for pharma and health care products, tablets, capsules, honey pills can automatically be filled.

Used for irregular products such as hardware, daily use, and electronic components, manual filling.

It has excellent high temperature resistance and is suitable for 121°C steam sterilization, high temperature sealing and hot filling applications. For hygienically demanding industries such as medical equipment and food, PP is preferred.

HIPS is capable of forming three-dimensional shapes and deep blister packaging, and is suitable for electronic accessories, toys, tools and hardware. Its raw material cost is much lower than that of PET and PVC, and it is a recyclable material.

PLA is made from renewable sources such as corn, sugar cane and cassava starch. It is 100% biodegradable and has the best environmental performance. Directly used for food, snacks, health products, capsules and other blister packaging.

Punches Frequency | 12-18cycle/min |

Material | PP, HIPS ,PLA, PET, PVC, PS |

Max. Forming length | 350mm |

Max. Forming width | 240mm |

Max. Forming depth | 42mm, customized |

Compressed air | 0.6-1.0Mpa |

Air consumption | >3m3/min |

Total power | 24kw |

Mould cooling | Tap water or recycling water, 60L/H |

Overall dimension | 5220×1150×1940mm(L×W×H) |

Weight | 3200kg |

This machine is widely applied in blister-type composite sealing packaging for liquid, sauce, small particle chili sauce, beauty products, health care products, daily necessities and similar materials. The products are sealed flat, leak-proof, easy to tear, and aesthetically pleasing, suitable for large-scale production of packaged products.

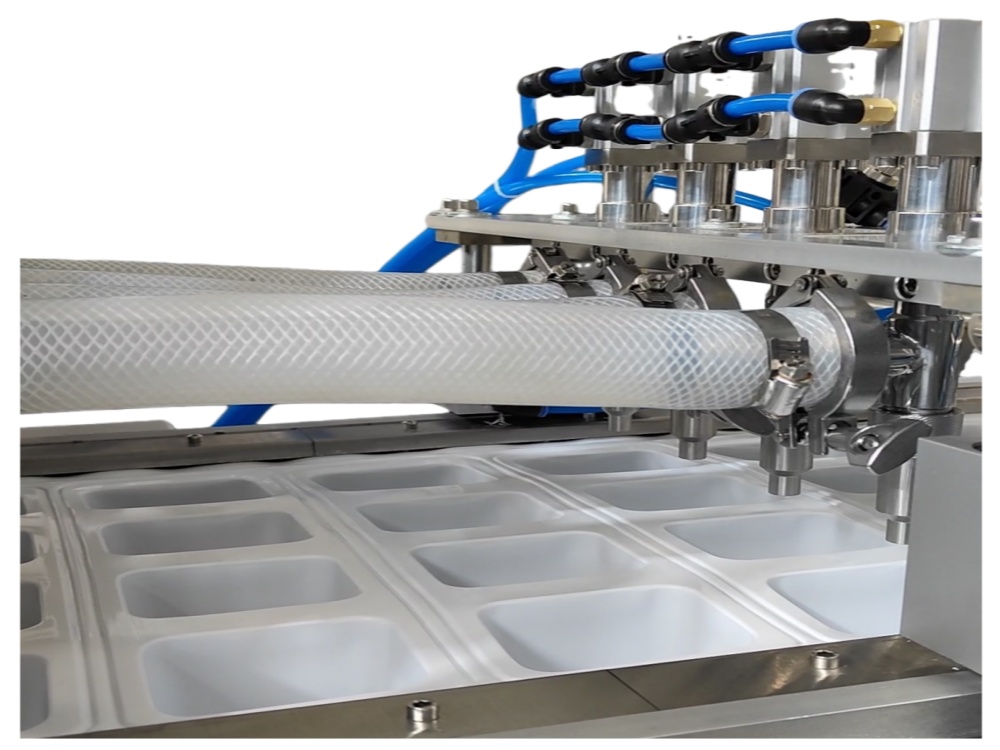

Working Process: → Unwinding → Plastic molding → Feeding → Heat sealing → Laser coding → Product punching → Finished product output → Waste material winding

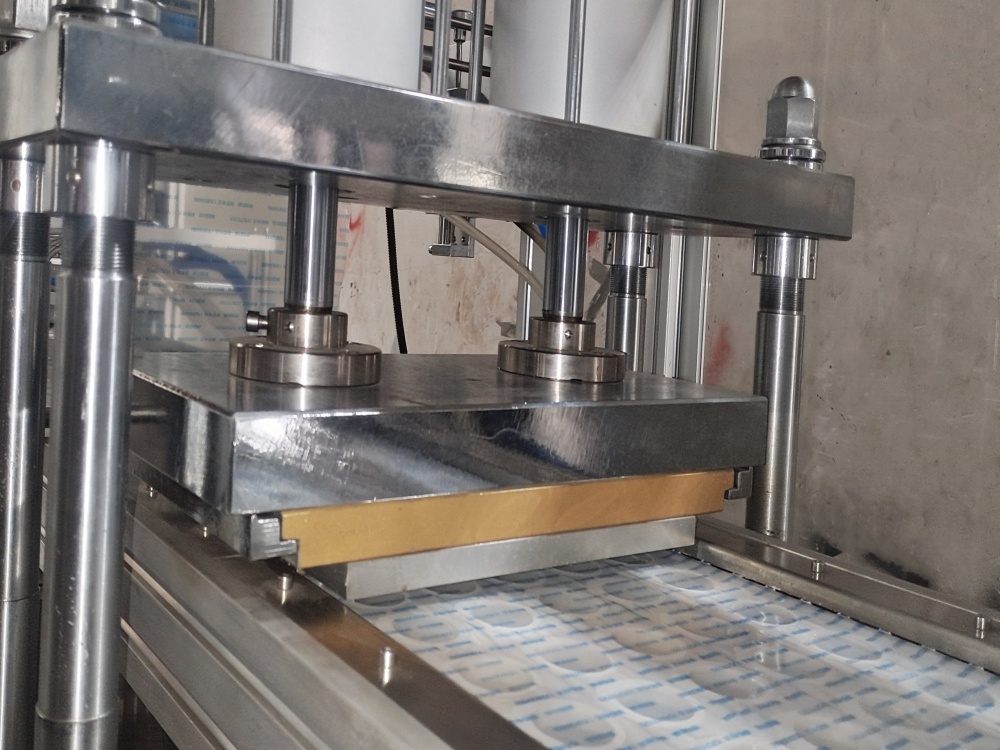

The upper and lower heating furnaces are used to heat the sheet material, ensuring a more uniform heating effect

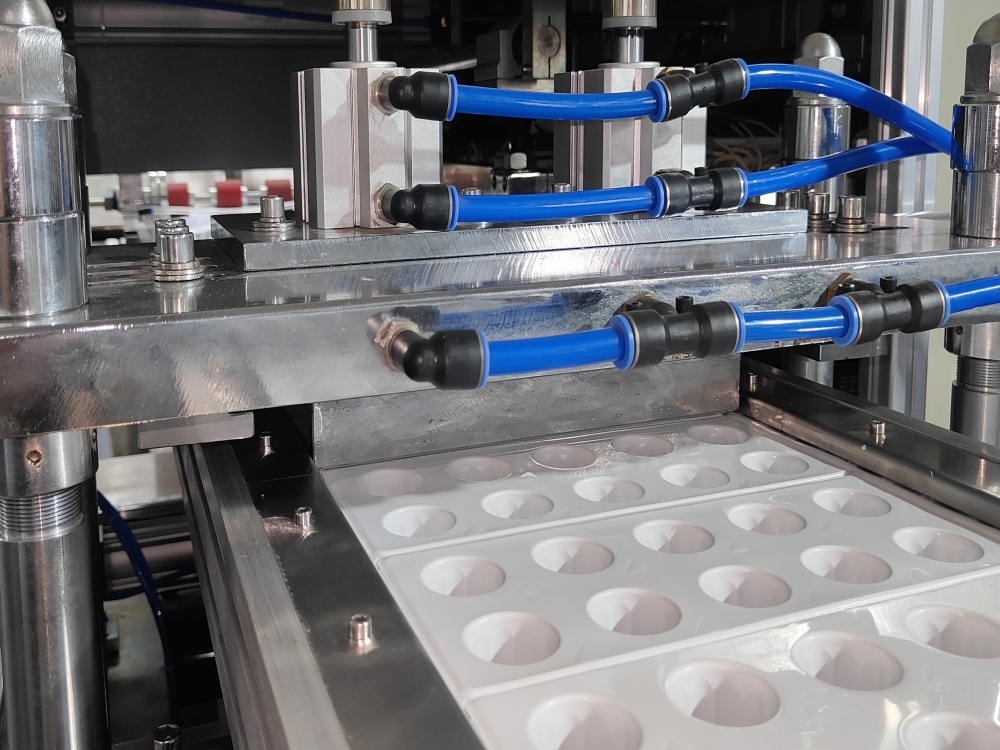

The mold forming is diverse; it can be customized, allowing for free design of products with any shape, and meeting user needs.

Wide range of filling capabilities, such as liquids, sauces, yogurt, creams, lotions, small particle hot sauces, etc

Using a servo motor for traction, the travel is more stable, and the dimensions of the four sides of the plate are basically the same.

The cutting is done using a metal knife, resulting in a smooth and flat cut surface. To facilitate opening and for ease of access at the opening area, the knife can be cut along the line.

The discharge port is equipped with a conveyor belt, and the finished products automatically come out.

Customized mold according to customer requirements, to meet the needs of customers for different shapes of product packaging. Blister molding, filling, film capping, heat sealing, punching, flow in one step, suitable for large batch of products packaging production, greatly reduce labor costs.

The cover material of the whole machine is food grade 304 stainless steel and aluminum alloy and is assembled. It is tall and durable in appearance.

On electric components, we adopt imported brands with Siemens, SMC, Omron high-end components.

We have in-house mold R&D department to design the molds according to the customers blister samples or drawings.

As 18+ years of PP blister forming machine manufacturing experience, we sold the machines all over the world and offer online and offline technology guidance.

You can get a price of this model or send us any question to get any information you would like to know, we will reply to you soonest.