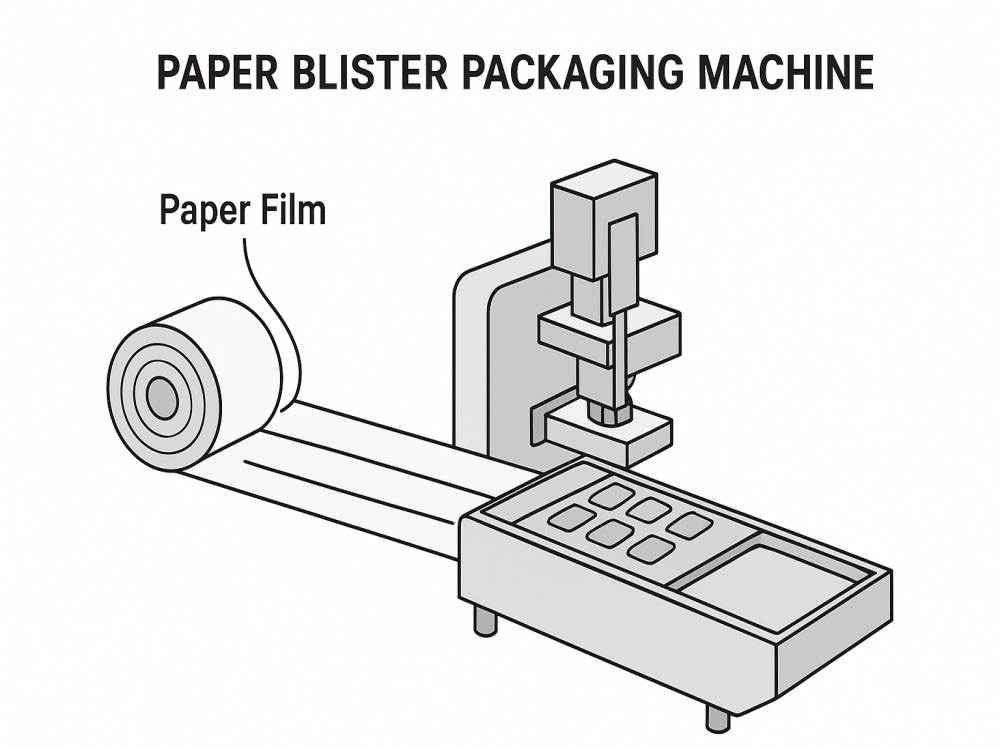

The paper-plastic packaging machine is specially designed for brands making the transition to eco-friendly blister packaging.

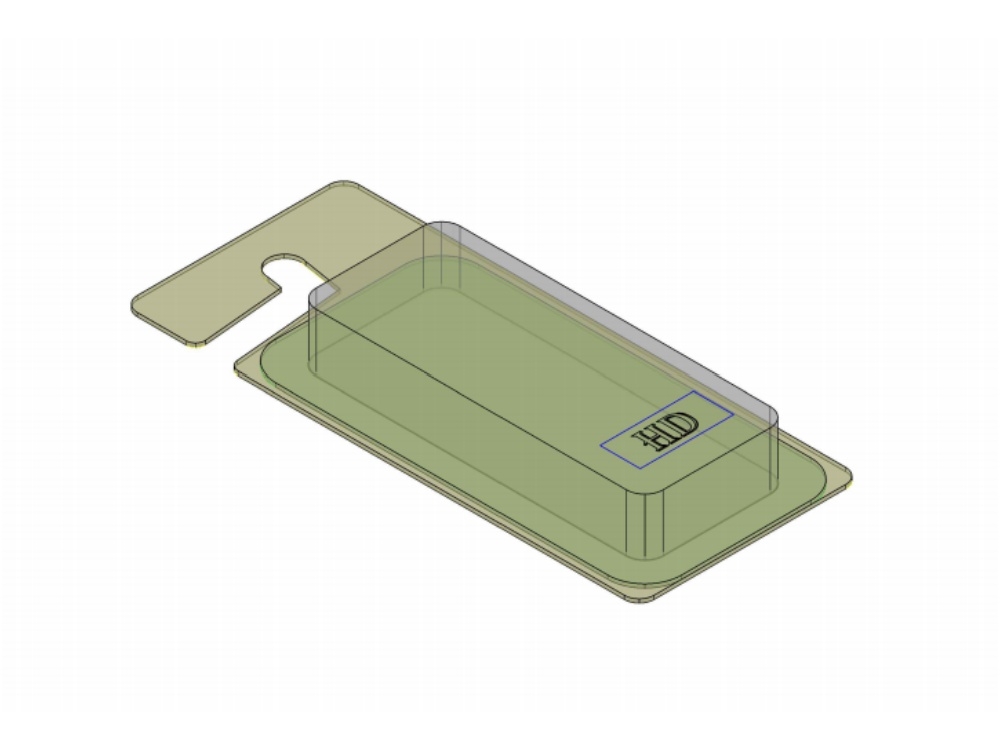

It can produce paper trays and seal them with recyclable or biodegradable plastic films, offering an elegant appearance, strong product protection, and significantly reduced plastic usage.

It is suitable for consumer goods, electronic products, personal care items, hardware tools, cosmetics, and product lines that emphasize environmental protection.

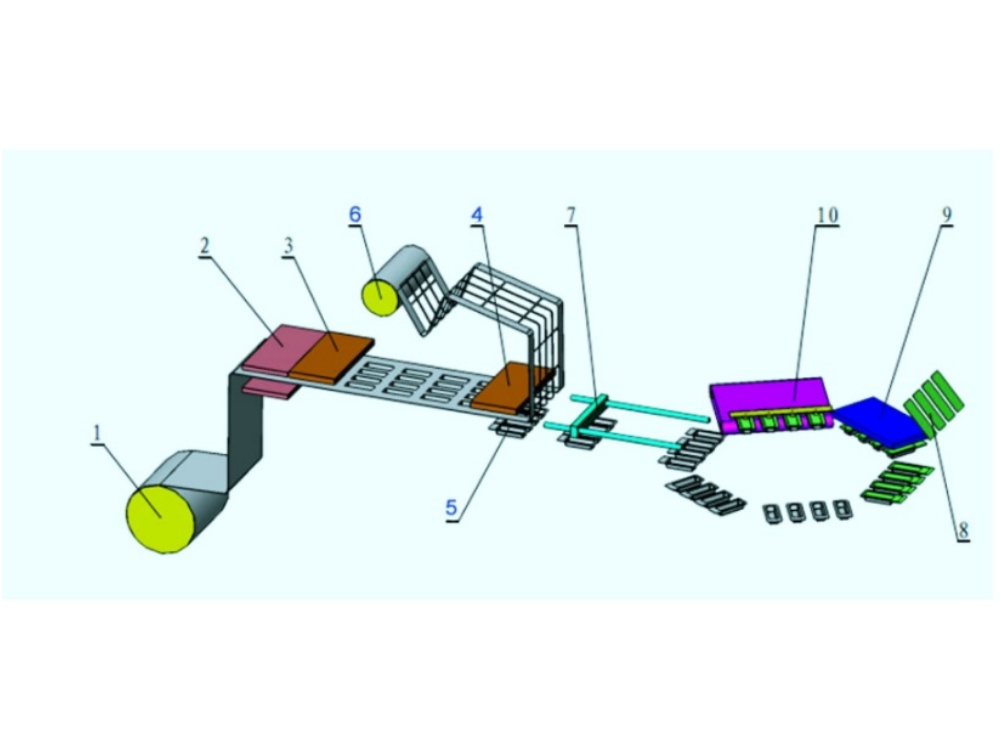

1.Plastic Material Release 2. Plastic Film Pre-heating 3. Blister Forming

4. Blister Cutting 5. Stripper 6. Edge Material Collecting 7.Tray conveying

8. Automatic Feeding Paper Card 9. Tray Paper Heat Sealing 10. Finished Products Output

The paper-plastic blister packaging machine is compatible with the paper-plastic composite film, with accurate molding and firm sealing, which can complete the product packaging efficiently. It has the advantages of dust-proof, moisture-proof and product integrity protection. Simple operation, low energy consumption, suitable for small and medium batch production in many industries, improve packaging standardization and product added value.

Use recyclable paper cards + biodegradable plastic film to reduce plastic usage by 70–90%. Perfect for companies adopting green, recyclable, biodegradable packaging and preparing for EU/US plastic reduction regulations. Suitable for sustainable product lines.

Servo-driven forming station ensures: clean cavity edges, high stiffness paper trays, uniform pressure distribution, stable forming of thick paper (up to 1.5 mm depending on model). Great for premium packaging such as electronics, cosmetics and retail products.

Compatible with a wide range of sustainable packaging materials:

• Laminated paper boards / kraft paper / coated paper

• PET / PLA / PE,recyclable transparent films

Thanks to servo control + PLC + touchscreen interface, BH-350F offers:

Servo-driven forming, sealing, punching, and stacking ensure precise alignment and consistent sealing quality.

Suitable for packaging with paper and plastic in the industries of hardware ,medical equipment , toys , batteries , electronic products, auto parts, commodity ,cosmetic , rubber products , kitchen ware etc. multi-cavity mold options. quick-change mold design.

It can be applied to the various kinds of packaging for products-stationery, industrial paperboard, plastic blister package widget, medical equipment, toys, battery, electronic product, automobile, motorcycle accessories, commodity, cosmetics, rubber products, tableware and cooker. For example: Medical injection, injection syringe, toy car, electronic torch, sparking plug, toothbrush, lipstick, mask, chopstick, shaver, scissor, hook, cleaning ball, bottle opener, correction fluid, ball-point pen, pencil, pencil sharpener, etc.

It’s especially suitable for companies with low production capacity that has various products and acquires changing molds frequently.

Eco blister packs for earphones, chargers, cables, accessories, small gadgets.

Toothbrush, razor, comb, facial tools, beauty tools, sponges, applicators, skincare accessories.

Blister cards for screws, blades, tools, batteries, accessories.

Cutting Frequency | Paper/Plastic (75mm*100mm*4) 10-25 times/min | |

Production Capacity (uph) | Paper/Plastic3000 Strips/h | |

Adjustable Travel Range | 35-160mm | |

Max. Forming Area | 340*160mm | |

Max. Forming Depth | Paper/Plastic 38mm(Special machine50mm) | |

Forming and Heating Power (up and down) | 1.8KW(X2) | |

Heat Sealing And Heating Power | 3.5KW | |

Total Power | 380V 50HZ (480V 50HZ) 10Kw | |

Main Motor Power | 1.5KW | |

Air Pump Volume Flow | ≥0.6m3/min | |

Packing Materials | Roll | ≤400(diameter)x350(width)x0.2-0.5mm(thickness) |

Paperboard | ≤350x200x0.5mm (L*W*H) | |

Wooden case size | 3650*2500*1850mm (L*W*H) | |

Total Weight | 1800Kg | |

Paper with low cost, flexible molding, suitable for multiple product specifications, easy to process and replace, clean and environmentally friendly without scratching packaging materials.

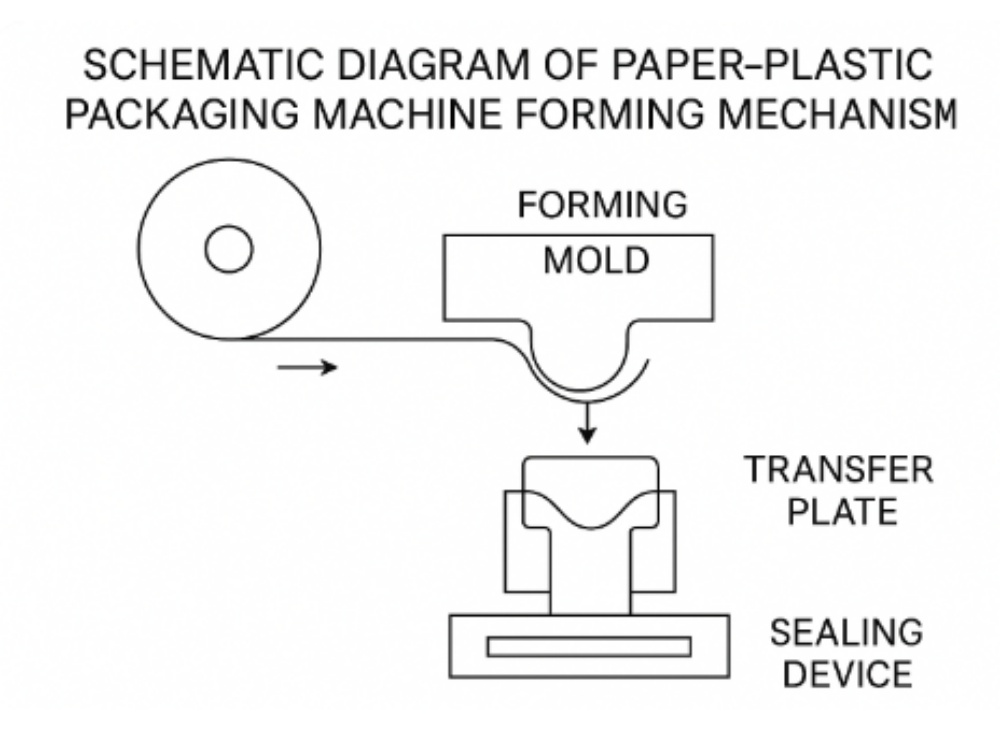

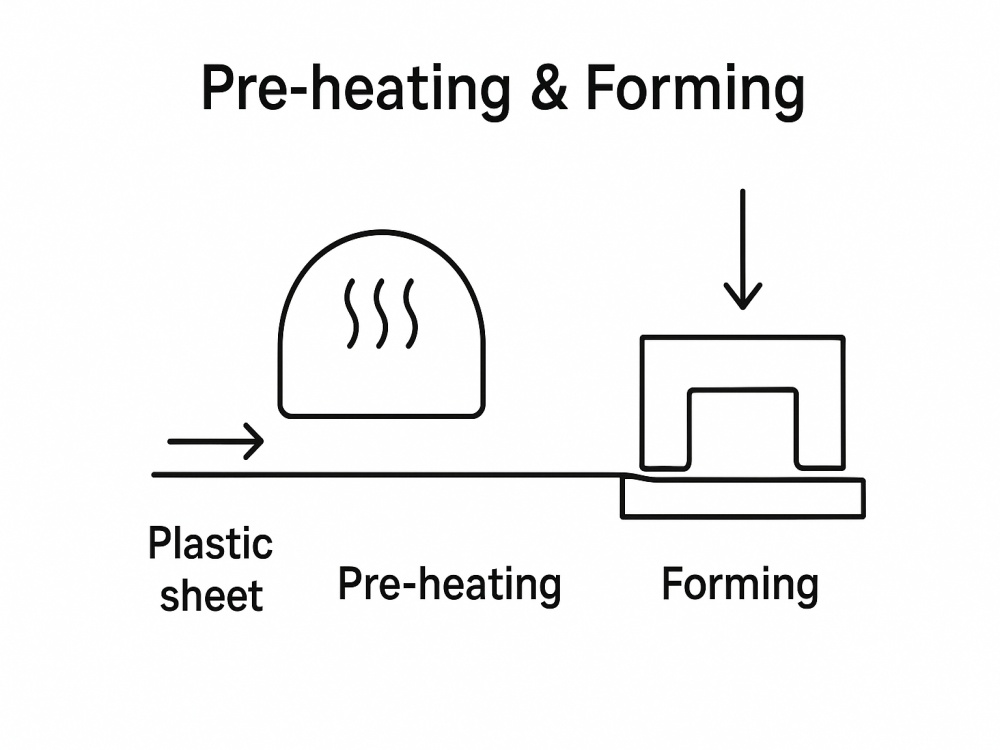

Preheat and soften the plastic film. The forming station then presses and shapes the film, laying a solid foundation for the subsequent product packaging.

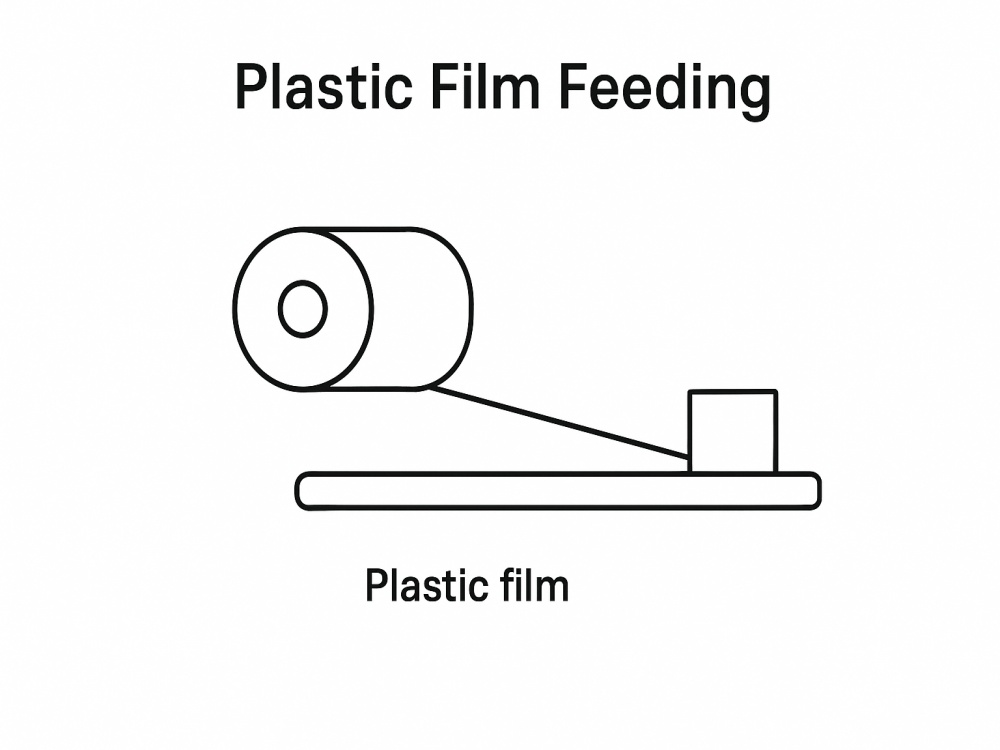

The film delivery is stable and precise, with controllable tension and no deviation. It is compatible with various plastic films and can efficiently adapt to continuous packaging production.

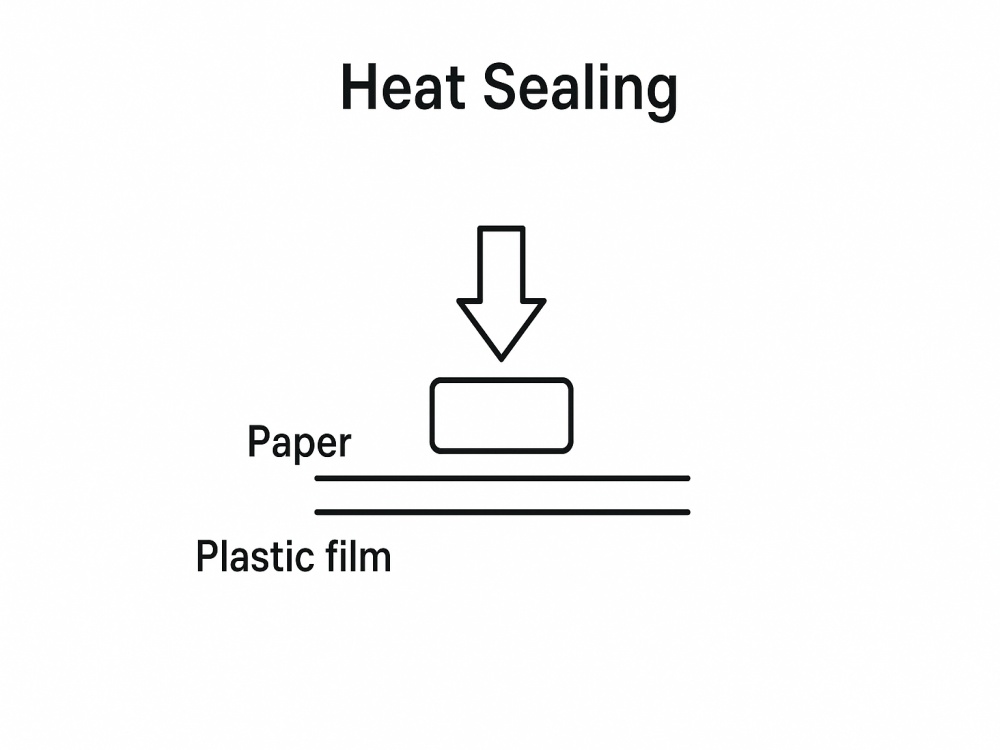

Precise heating and pressurization ensures that the plastic blister fits and seals tightly with the cardboard, preventing leakage and moisture absorption to ensuring the sealing performance.

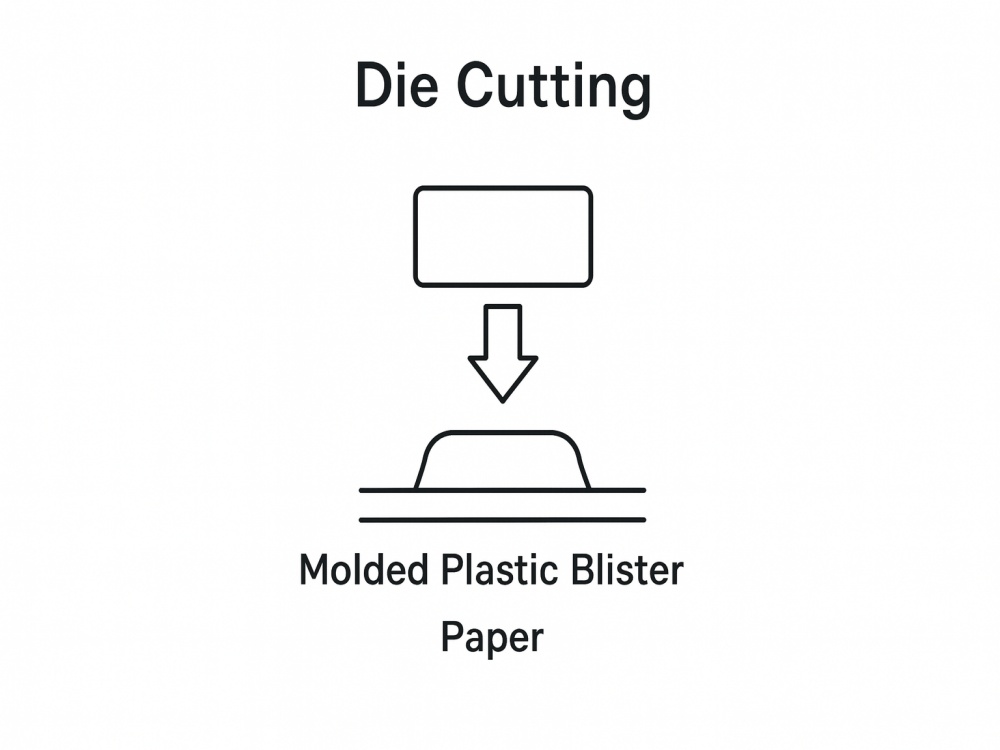

According to the preset specifications, precisely punch and shape the packaging pieces, separate the waste materials, and obtain neat finished products, which are suitable for storage.

Product code traceability, visual defect detection and label application to ensure quality compliance and information verifiability, and improve product identification and market competitiveness.

1. Can your machine work with 100% biodegradable films like PLA?

Yes. The machine supports PLA, PET, PE, and other recyclable films.

2. How do you design the blister mold?

You provide a product sample or 3D drawing → we design → confirm → produce.

3. What is the lead time for the machine?

Typically, 25–35 working days, depending on customization.

4. Can I produce fully paper blister packs?

Yes, with optional upgrades, full-paper “no plastic” packaging is available.

5. How difficult is mold change?

The quick-change system allows depending on the molds.

You can get a price of this model or send us any question to get any information you would like to know, we will reply to you soonest.