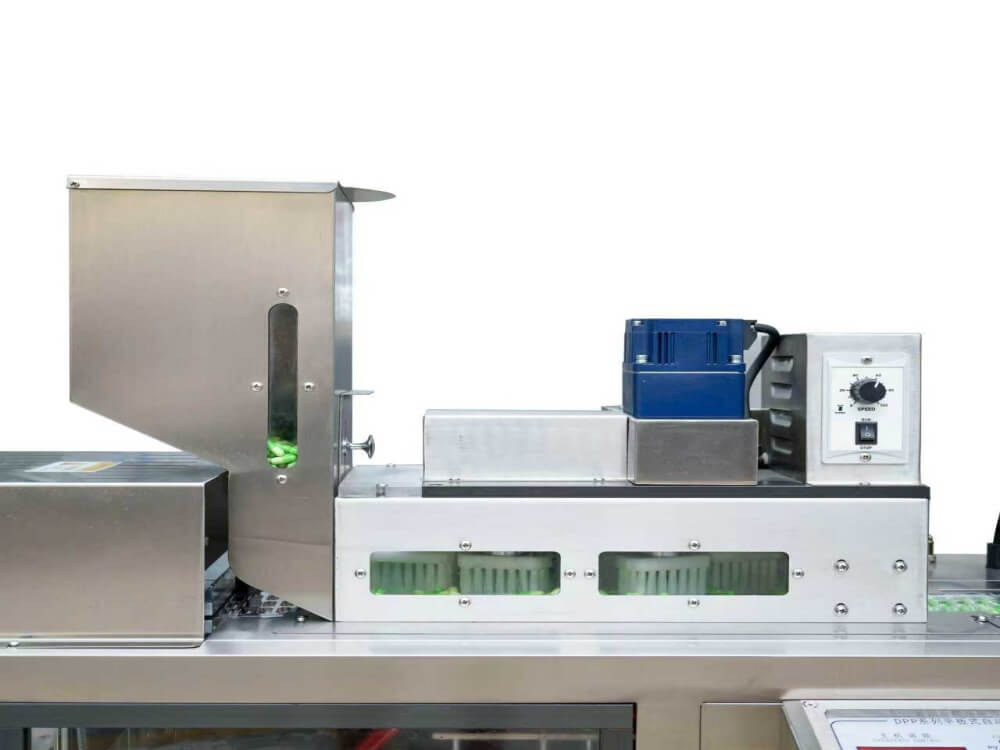

DPP 80 Blister Packing Machine is a small size Blister Packing Machine for very small production or sample production using in dosage room of hospital, middle or small pharmaceutical and nutrition products factory.

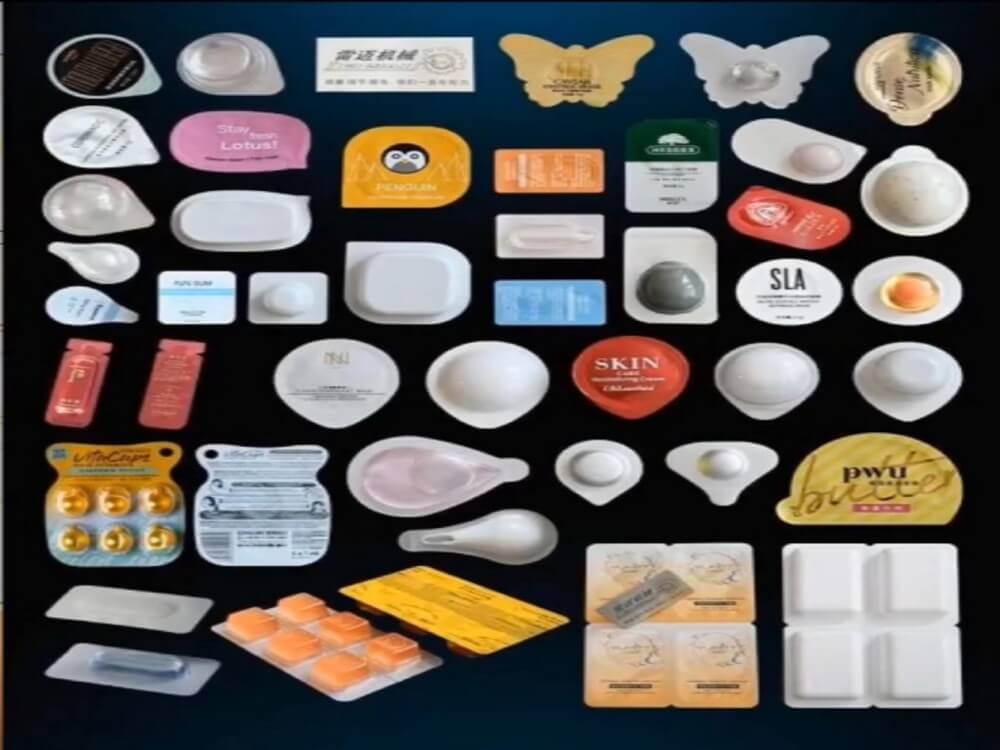

This mini Blister Packing Machine is widely applied in pharmaceutical, food, cosmetics, daily necessities, electronic, and medical device industries with Alu-plastic packing or Alu-Alu packaging, support almost all application and industry.

How is the working process of the DPP 80 Blister Packing Machine? It is an easy way to complete the blister packing, just a few steps for you to get the product packing completed.

Although the DPP 80 machine is small in size, but the function is absolute complete, and the effect is exactly same to the large packaging machine. The most important thing is save costs. It adopts the newest type high-power transmission mechanism to arrange the chain and drive the main driving shaft. The errors and noises of other gear wheel transmission can be avoided. Imported controlling system is adopted; also, it can be equipped with detecting and rejection function device for number of medicines according to the user’s requirement.

Whole machine body covered with 304 stainless steel, Compliant with GMP standards.

Stainless steel is durable enough to allow DPP 80 blister pack machine strong and durable, keep long-term production stability, not easy to damage.

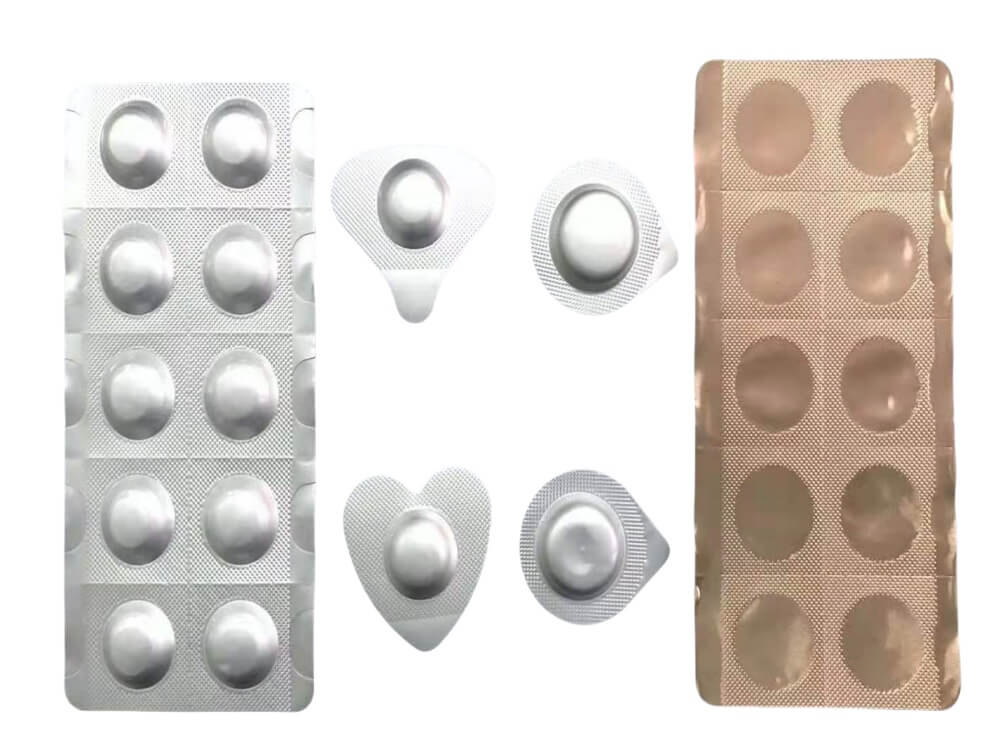

Our mini model DPP 80 blister packaging machine can produce varies of molds, such as capsule, pills.

According to your production requirements, you can flexibly switch different molds to be used for the production of different products.

DPP 80 small model blister machine suits to alu-pvc blisters pack, alu-alu blisters pack.

DPP 80 Mini Blister Packing Machines with a wide range of applications, not only in various industries but also suit for many different material requirements.

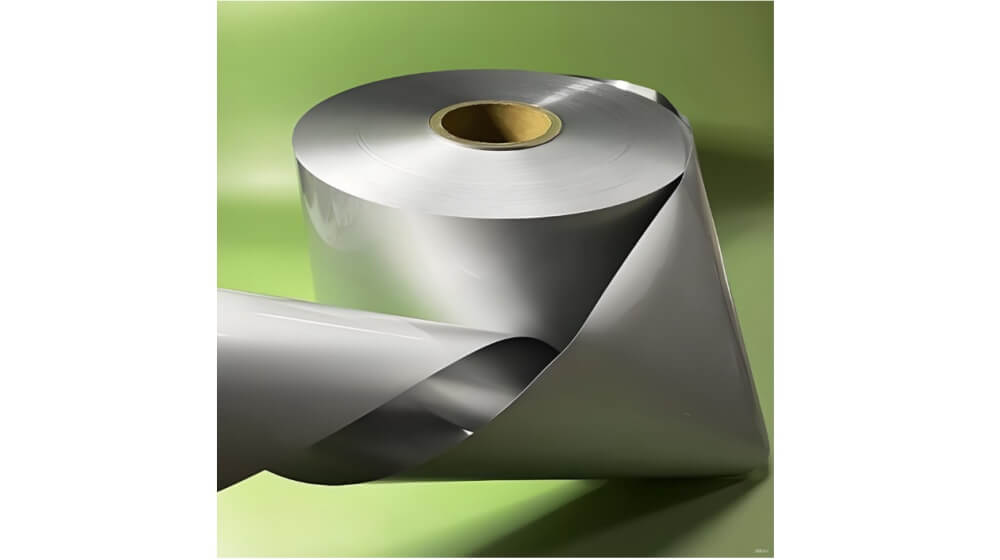

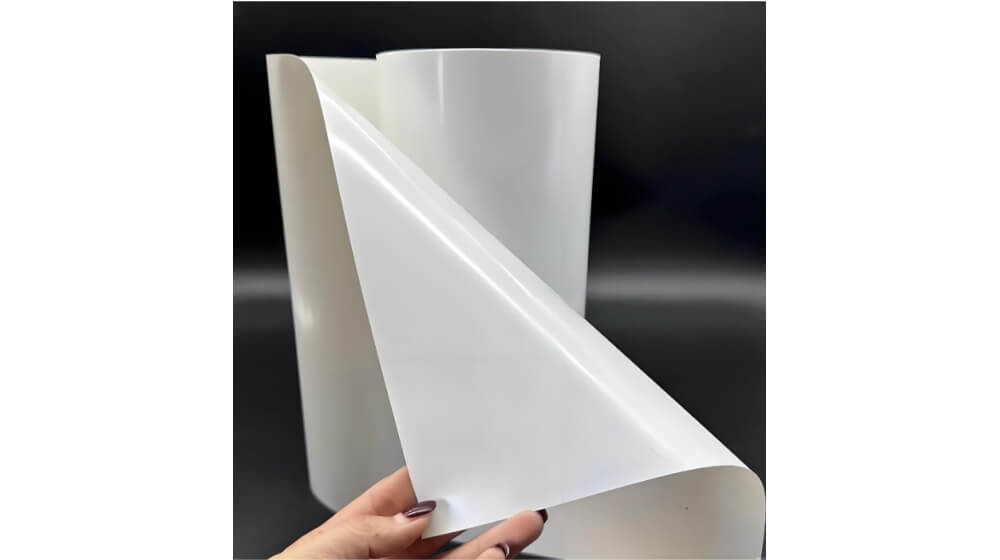

Different products such as tablets and food packaging all require different materials. The DPP 80 Blister Packing Machine can support almost all materials used in blister packaging on the market, including alu PTP, PVC, PET, PE, and PVDC materials.

PVC/ALU materials are the most commonly used in the industry, with high cost performance and good forming adaptability, which can meet the requirements of multi-scene packaging.

DPP 80 Blister Packing Machine can be used in the production of small batch material blister products.

Aluminum foil is used for products requiring high barrier, high sealing, safe and non-toxic packaging, including pharmaceuticals, food, medical devices and electronic components.

PVC is a widely used synthetic material. Its core advantages are low cost, strong processability and adjustable performance. It is widely used in pharmaceutical Industry, food Industry, medical device industry, daily necessities/cosmetics industry and electronic industry.

Except PVC, ALU materials, PE, PET, and PVDC are also the core auxiliary/composite material of Blister Packing Machine. PE mainly focus on cost performance and heat sealing, PET strong in physical strength, PVDC high blocking of focus.

PVC/PVDC film unwinding→ Heating → Forming → Product feeding (brush feeder / guide rail → Vision check → Heat sealing with aluminum foil → Batch coding / printing→ Perforation → Punching → Finished blister output

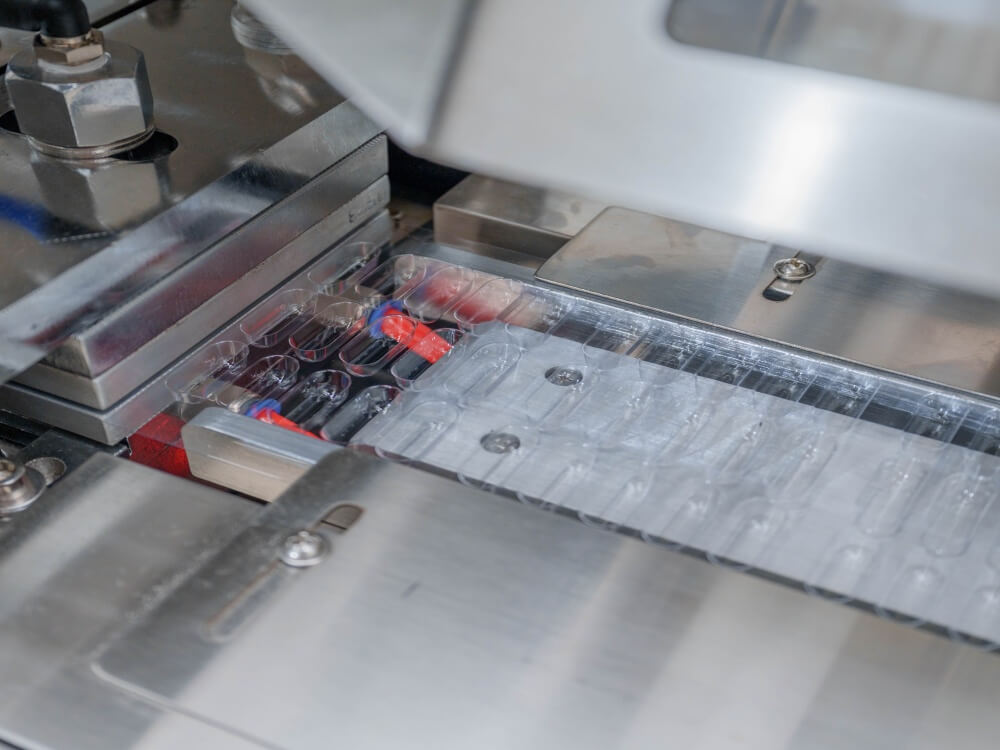

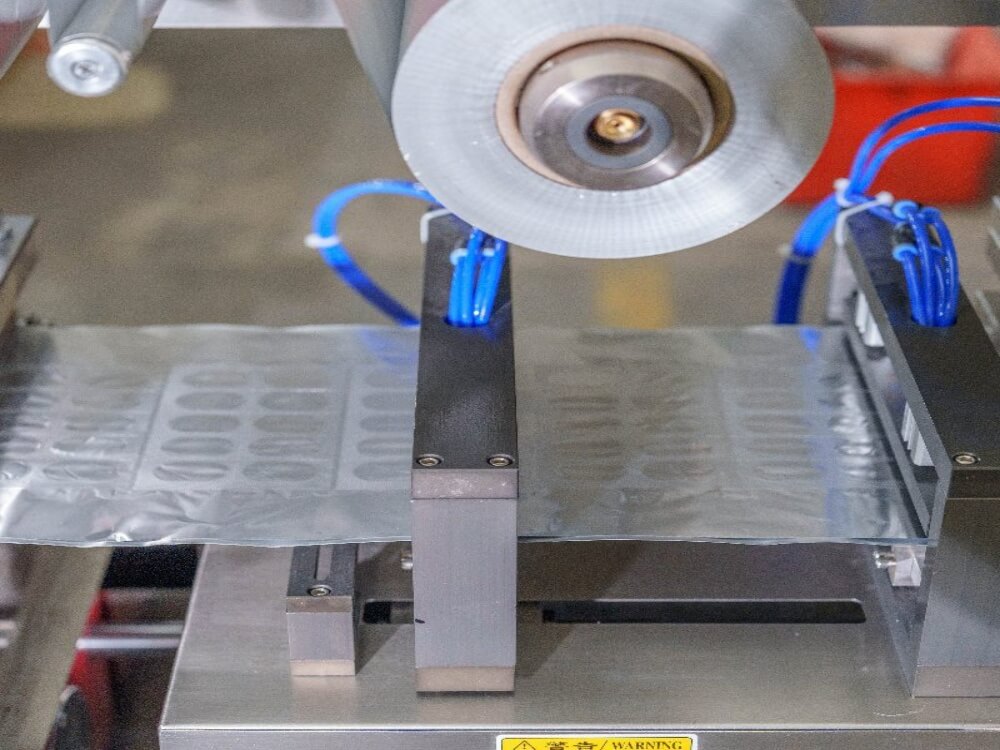

After heating the plastic sheet material (such as PVC/PET) to make it soft, individual blister cavities are formed, which are used to hold capsules.

The forming process of the blister machine mainly relies on the principle of heating and softening of thermoplastic materials → traction deformation → shaping and cooling.

Feeding Types: Manual or automatic (capsule/tablet feeder optional)

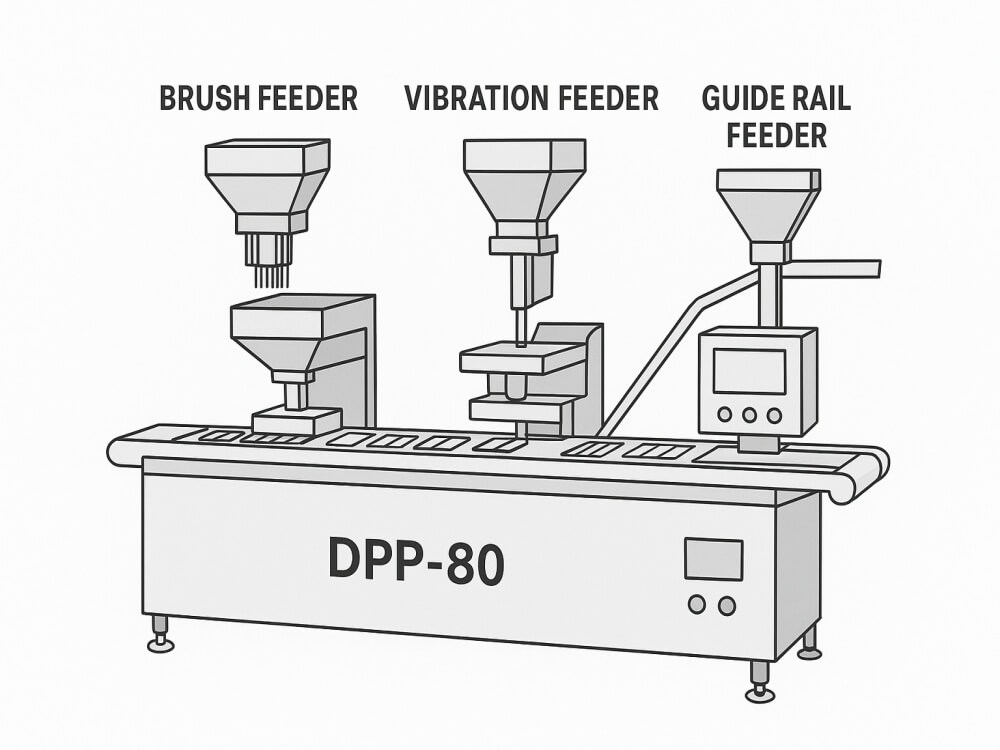

When feeding capsules into blisters, tt is mainly realized by a special feeding system. There are different feeders for different products blister packaging, such as universal feeder (Rotary Brush Feeder), guide rail feeder and vibrating+ track combination.

The formed plastic blister (made of PVC/PET/PVDE or Alu, etc.) is firmly sealed with aluminum foil or heat-sealing film to form a sealed packaging cavity, protecting the medicine from moisture, oxygen and contamination.

Punching is the process of cutting sealed blisters into individual blister packs using precision stamping dies to ensure that the shape and dimensions of each package are consistent.

Whether you use it to package cosmetics or pills, our DPP 80 blister packing machine can precisely punch and shape without any shifting or other issues.

Deliver the already punched blister packs (such as the finished products capsules or tablets) orderly out of the machine. Ensure that the blister plates are not squeezed or scratched, and keep the appearance intact.

DPP 80 blister packing machine equipped with automatic discharge system, can ensure that your products come out in good condition

DPP 80 Small Blister Packing Machine is compact, easy to operate, customization and so on. The DPP 80 mini blister packaging machine, although small in size, can package a wide variety of products. Tablets, capsules, granules; Candies, chocolates, nuts, freeze-dried food. Disposable syringes, medical dressings, minimally invasive instruments. Small size skin care products, cosmetics samples, toothpaste strips. Small components, chips, sensors and so on. Widely used in pharmaceutical, food, cosmetics, electronics and other fields.

This DPP 80 blister packaging machine is highly suitable for pharmaceutical research laboratories, clinical trial institutions, as well as drug production and packaging departments. It can meet the needs of small-scale drug production, stability studies, sample preparation, etc.

If you need DPP 80 blister packing machine pack your medicines or tablets, contact us and customize the molds you need.

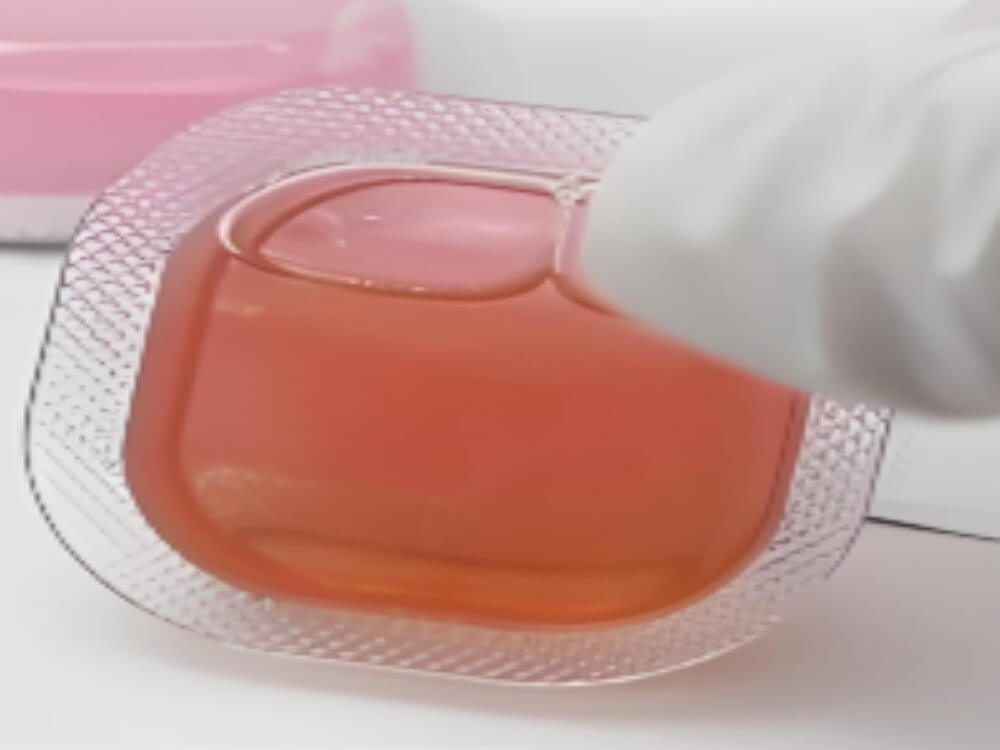

DPP small blister packing machine can be used for packaging solid foods such as biscuits and snacks as well as single dose liquid syrup, olive oil, honey and other liquid or semi-fluid food. Customized designs can be made according to the characteristics of the food and packaging requirements to ensure the quality and shelf life of the food.

DPP Mini Blister Packing Machine can be used for cosmetics packaging, such as emulsion, eye shadow, lipstick etc. For some small-sized, high- value cosmetic samples or single products, the equipment can provide exquisite packaging to protect the cosmetics from external environmental influences, while improving the beauty and quality of products.

DPP 80 Mini Blister packing Machine for various electronic components and hardware products, such as resistors, capacitors, chips, sensors, micro batteries, etc. Customized mold designs according to the size and shape of electronic components to ensure that electronic components are not damaged during transportation and storage

DPP 80 blister packing machine can be used for packaging some small medical devices, such as disposable syringes, acupuncture needles, etc. It can provide excellent sealing and sterile environment, effectively block bacteria, dust and moisture, and meeting the standards and requirements for medical device packaging.

The DPP 80 Blister Packing Machine is the mini model is specially designed for small-batch and customized small production. It is ideal for laboratories, R&D centers, and small-scale pharmaceutical or health supplement manufacturers. The DPP-80 operates at a speed of 10–33blisters per minute (depending on blister size, forming material, and product type). Production speed varies depending on packaging materials and product specifications. In short, the DPP-80 balances precision, efficiency, and flexibility, making it a perfect choice for small-scale blister packaging needs.

PVC/Alu blister: approx. 1200-1980 blisters/hour.

Alu/Alu cold forming: approx. 900–1200 blisters/hour.

Model | DPP-80 |

Punch frequency | 10-33times/min |

Production capacity | 2400plates/hour |

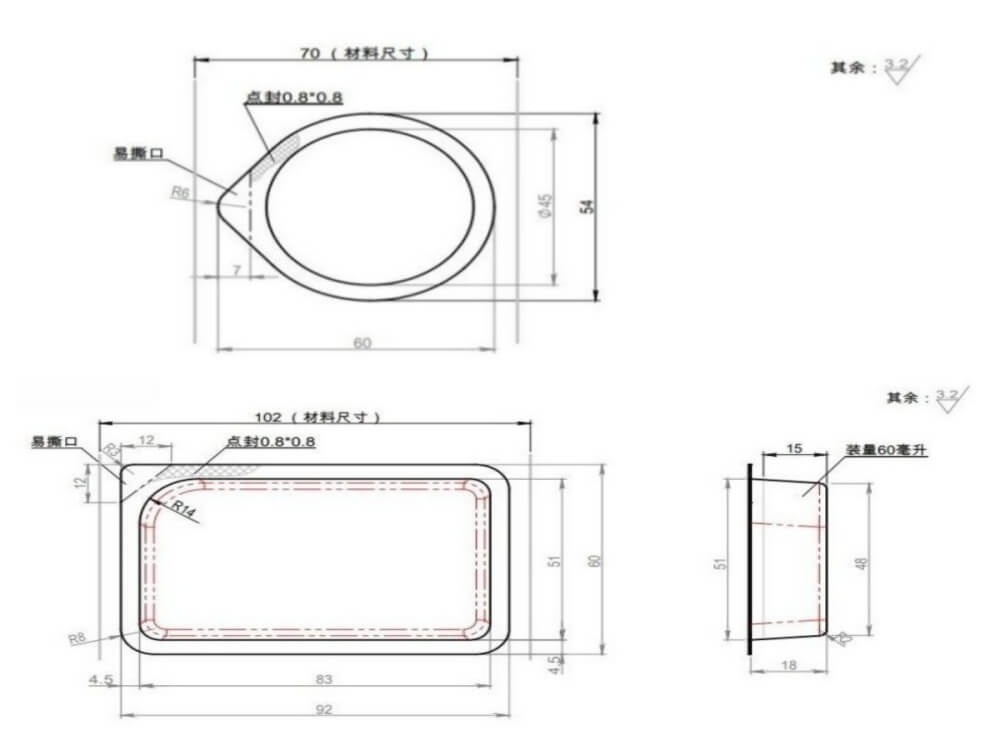

Max. Forming area & Depth | 105*70(standard depth ≦12mm), Max. Depth 25mm (As adjusted) |

Standard Stroke range | 30-80mm (can be designed as per user’s required) |

Standard plate size | 80*70mm (can be designed as per user’s required) |

Air pressure | 0.4-0.6Mpa |

Compressed air required | Air compressor≥0.3m3/min |

Total power supply | 380V/220V 50Hz 2.8Kw |

Main motor | 0.75Kw |

PVC hard Film | 0.15-0.5*110 (mm) |

PTP Aluminum film | 0.02-0.035*110 (mm) |

Dialysis Paper | 50-100g*110(mm) |

Mould cooling | Tap water or Recycling water |

Overall Dimension | 1840*590*1100 mm (L*W*H) |

Weight | Net 450kg Gross weight: 520kg |

Noise index | <75dBA |

DPP 80 Small Blister Packing Machine as be customized for you with many advantages.

The machine uses a manipulator traction device and has an adjustable range of movement, suitable for blister packaging of various sizes. The flat plate structure can package products with special shapes, such as oval, square, triangle, liquid, paste and syringe, etc. The entire feeding, forming, heat sealing, stamping, lot number printing and cutting process can be completed automatically and continuously.

According to the shape, size and quantity of the customer can design different cavity number and layout of the blister mold.

The customer can customize the blister depth, seal shape, cutting method (flat, round corners, easy-tear, etc.)

Choose different feeding systems according to the product type such as Brush feeder, vibrating feeder, manual feeding platform.

Compact structure, equipped with frequency converter, easy to operate and clean. Compact body and occupies a small area (about 1.8㎡), easy to put in a laboratory or small workshop.

The electrical appliances adopted imported control system, suitable for frequent changeovers. Touch screen PLC control system can be equipped to achieve temperature, speed, vacuum degree and other digital control.

Ideal for trial production, stability tests, or small customized orders.It takes only 15-20 minutes to change the mold, which is ideal for multi-product switching

As a professional source manufacturer of blister packaging machines, YABO Machinery specializes in designing and producing high quality equipment for the pharmaceutical, healthcare and laboratory industries. Our DPP 80 Blister Packing Machine represents YABO’s commitment to precision engineering, customization and reliability. With its compact structure, flexible mold design and intelligent control system, DPP 80 For small volume production, clinical trials and R & D packaging projects.

Each machine is built and tested in-house to ensure consistent performance, stable seal quality and long service life.Choosing Yabo means working with direct manufacturers for better technical support, competitive pricing and full customization service from design to delivery.

You can get a price of this model or send us any question to get any information you would like to know, we will reply to you soonest.