As a professional DPP 150 Automatic Blister Packaging Machine manufacturer, we offer high precision thermoformed blister solutions for tablets, capsules, soft capsules, candy tablets and small consumer products.

Our DPP 150 is compact in size, stable in performance and flexible in die changing-ideal for laboratory, small scale production and small batch packaging lines. If you are looking for a reliable supplier of dpp150 blister packaging machine, pharmaceutical blister packaging manufacturer or automatic small blister packaging machine, you are welcome to consult us and we will provide detailed solutions.

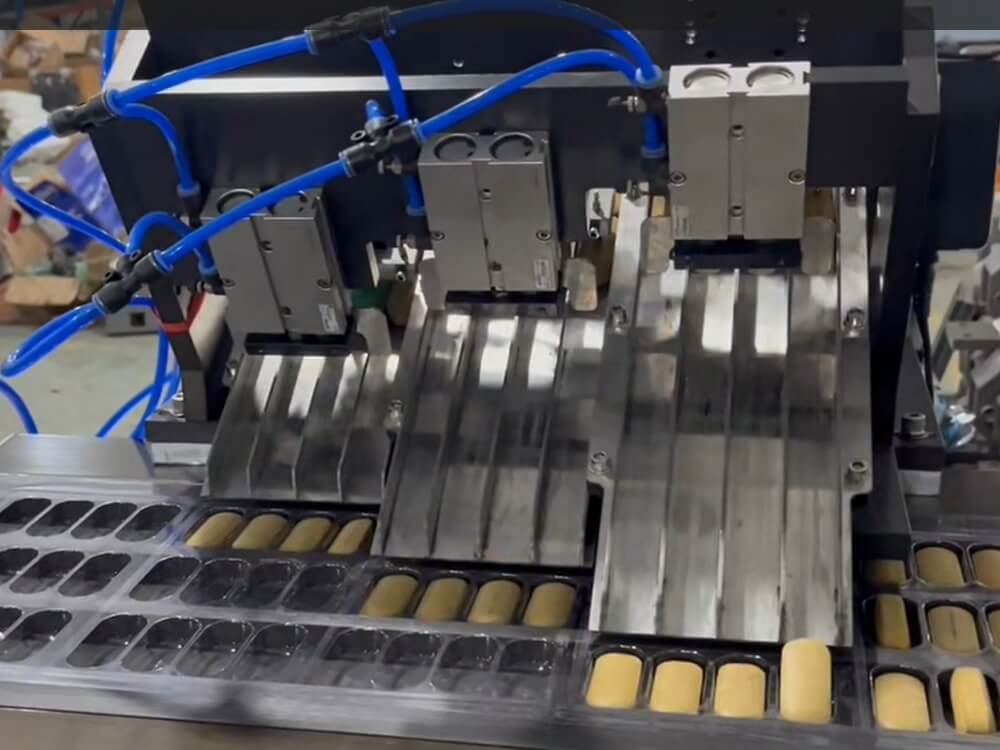

This machine running video show you the producing process, from film forming, feeding, how is the feeder working, sealing, servo traction, waste rewinding, cutting and finished products output whole line.

The DPP 150 is a compact thermoforming blister packing machine designed for PVC/Alu, PET/Alu, Paper-Plastic and other forming materials. It offers: low noise operation, fast format change, accurate PVC forming, stable aluminum foil sealing, and consistent blister cutting.

It is widely used as a lab blister packing machine, small tablet blister machine, and capsule blister packing equipment for R&D centers, pharmaceutical factories, nutritional supplement brands, and contract packaging companies.

The DPP150 blister packaging machine is compatible with a wide range of materials, and is suitable for packaging in various fields such as medicine and food. It complies with GMP requirements. The common materials and their characteristics are as follows:

The price of PVC raw materials is relatively low, and no complex additives are needed during the processing. it suitable for large-scale industrial production.

PE (polyethylene) has a strong inert property and does not undergo chemical reactions with most medicines, foods, etc. It can prevent contamination of the contents and ensure the safety of the product.

The aluminum foil is opaque and can completely block the passage of light, preventing the products from deteriorating due to exposure to light. At the same time, it can protect the privacy of the products.

The DPP 150 blister machine working process as following:

PVC/Alu/PE film Loading→ Heating → Forming → feeding → Aluminum foil Heat sealing → Punching → Finished blisters output.

It adopts photoelectrical controlling system to make PVC, PET, Aluminum/Aluminum material to be automatically fed.

Adopts plate-type mould, positive-pressure forming. The PVC heating and forming station designed for stable thermoforming and consistent blister cavity shape.

Automatic feeder for accurate filling of products into blister cavities.The feeder is fitted with dust exhaust joint so can overcome the dust problem during feeding.

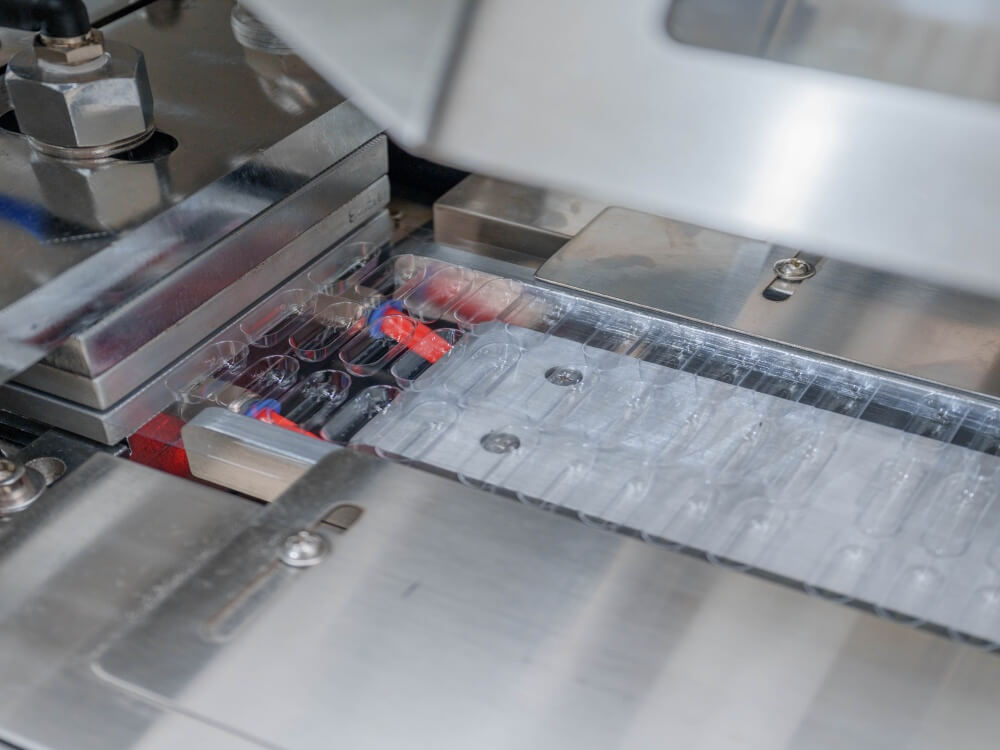

High-precision sealing station that ensures strong bonding between PVC blister and aluminum lidding foil.

Punching and cutting unit for clean blister edges and stable cutting performance. With frequency stepless speed regulating, the punching frequency reaches 15-35times per minute

The core role is to efficiently collect and dispose the corner waste after blister molding to ensure continuous production and clean environment.

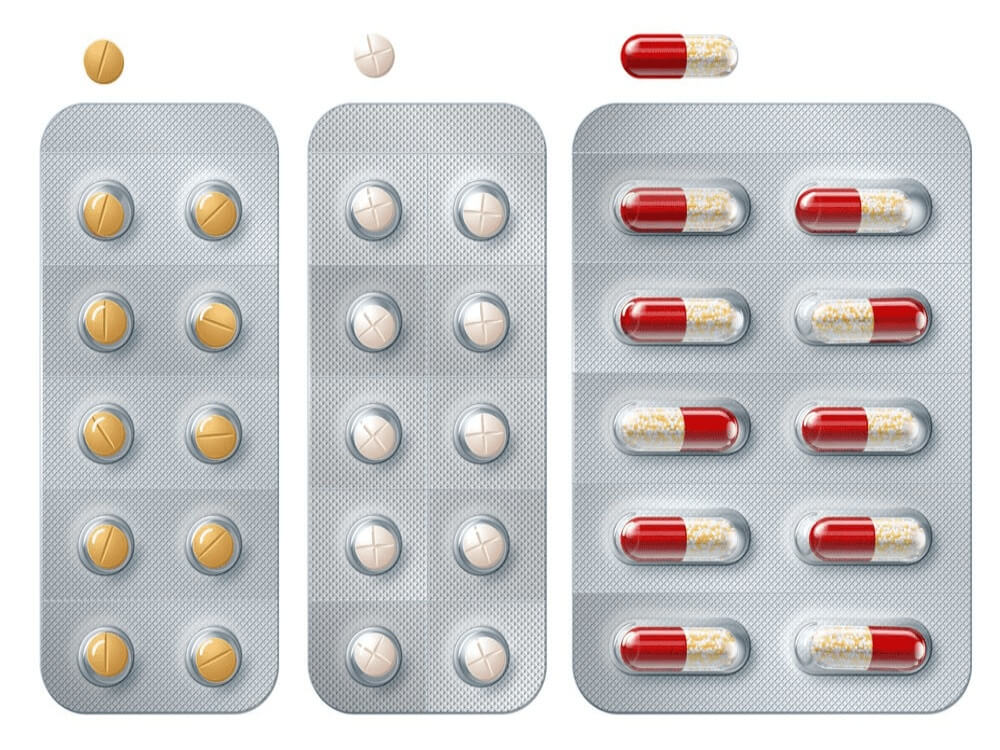

Finished blister packs for tablets, capsules and others produced by the DPP 150 machine.

Compact Design for Limited Space, light weight, cramped structure, easy operation and maintenance.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Consistent blister cavity forming, ideal for tablet blister packaging and capsule blister sealing. Supports high-barrier materials and custom cavity shapes.

Automatic feeding system. Capsule brush blister feeder, tablet blister vibratory feeder, customized feeding for irregular products.

Adopts registering matching heating so that can reduce the heat energy loss of heater to the least, and the required temperature will be greatly reduced.

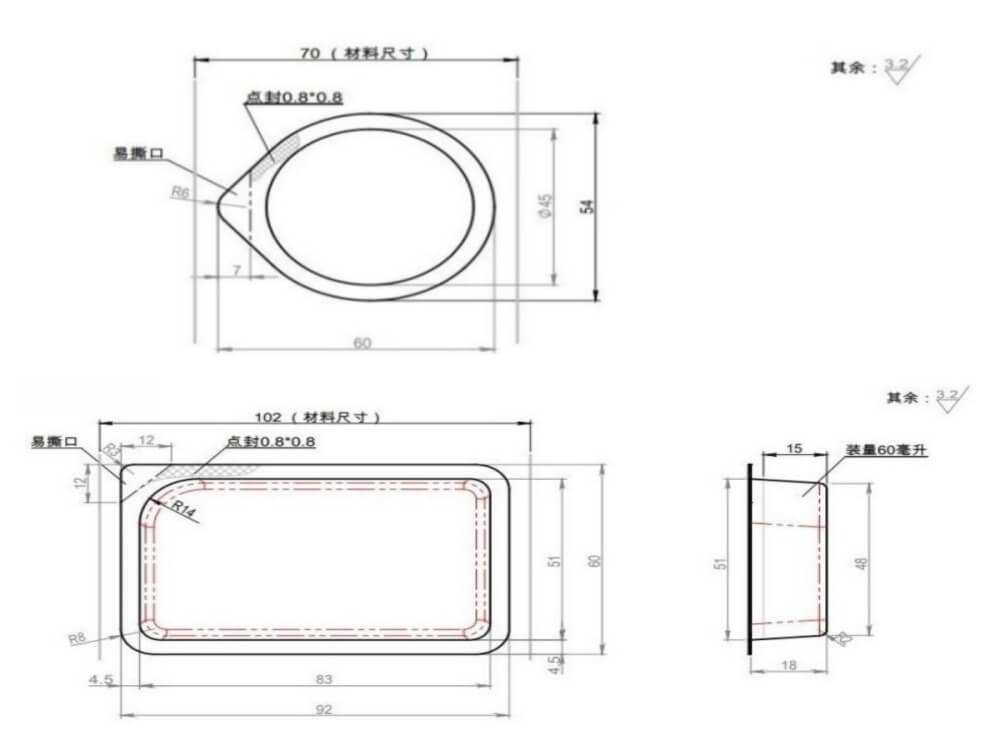

Tool-free format change. Custom blister mold manufacturer, easy setup for different blister sizes. Perfect for small batch blister production.

The DPP 150 blister machine is a medium capacity intermittent flat-plate blister packaging machine, the core is applied to the blister packaging of medium and small batches, multi-specification solid preparations and small products.

It is suitable for conventional solid dosage forms such as tablets, capsules, granules and pills, and can also be used for the individual packaging of small-dose traditional Chinese medicine decoction pieces and external patches.

Standardized blister packaging for vitamin tablets, probiotic capsules, dietary supplements, softgel and other products, meeting food-grade packaging requirements.

With the characteristics of low-dose packaging and the ability to accommodate various forms of materials and packaging materials, it is mainly used in the cosmetics industry for one-time samples and portable packaging.

This kind of small packaging not only meets the needs of consumers to taste fresh and portable food, but also helps brands expand sales scenarios such as tasting clothes and hand gifts.

It can package small beauty tools, electronic components, small hardware accessories, disposable consumables, etc., and achieve single or multiple item combination packaging.

Punches Frequency | 15-35times/min |

Max. Forming area | 140×100mm |

Max. Forming depth | 16mm |

Stroke travel range | 40-120mm, adjustable |

Main power supply | 1.5kw |

Upper Heating power | 0.8kw |

Lower Heating Power | 0.8kw |

Heating Power for Heat Sealing | 0.7kw |

Air Pump Volume Flow | ≥0.2m3/min |

Air Pressure | 0.4-0.6Mpa |

PVC hard film | 0.25×150 mm |

Aluminum foil | 0.02×150mm |

Mould cooling | Tap water or recycling water |

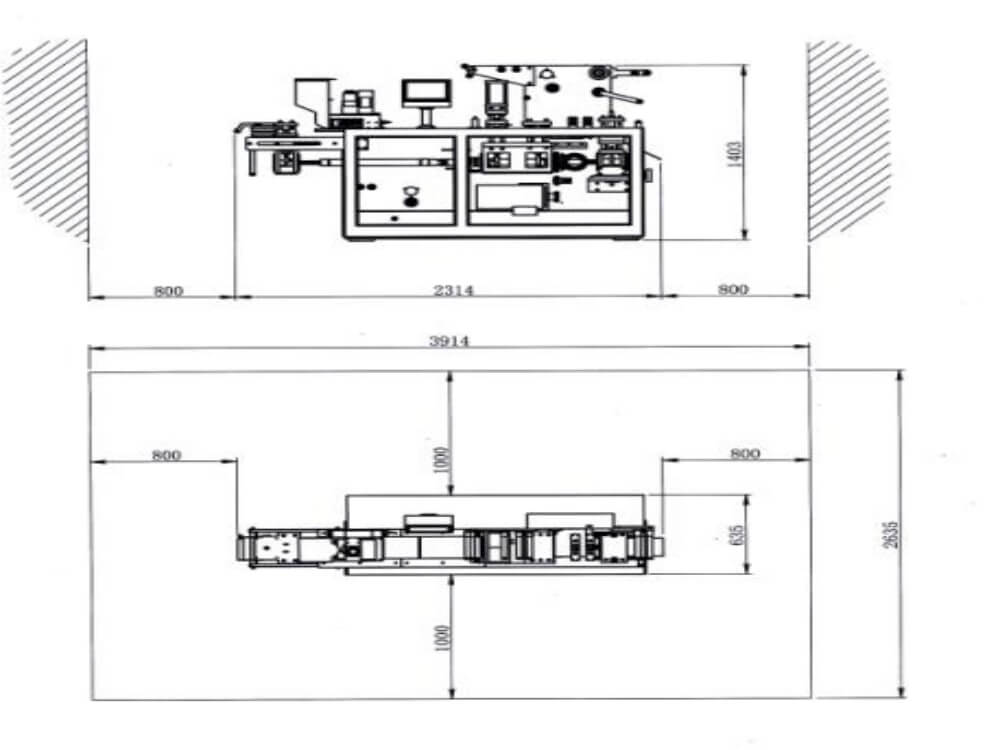

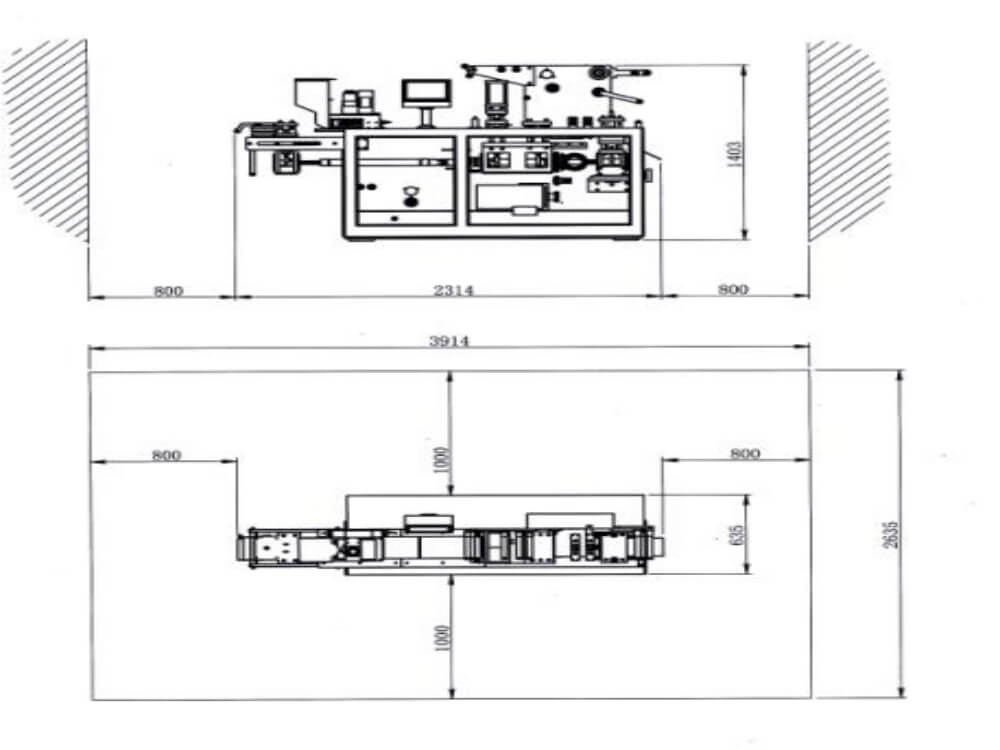

Overall dimension | 2450×570×1550(L×W×H) |

Weight | 620kg |

With automatic control, flexible production replacement, and stable compliance, the DPP 150 blistering machine can meet the needs of small and medium batch production in multiple industries, while giving consideration to the convenience of operation and cost economy.

We are a direct blister machine manufacturer, producing every DPP 150 in-house.

Custom blister molds for tablets, capsules, candy, hardware, cosmetics and other regular or irregular products.

Professional online training & installation support, video training, spare parts supply, long-term technical support.

Fast delivery and long-term spare parts supply, we supply DPP 150 units to Europe, Southeast Asia, Middle East, Africa, and South America.

Pricing depends on mold size, feeding method, and material type. Contact us for a detailed DPP150 blister machine price quote.

PVC/Alu, PET/Alu, Paper-Plastic, and high-barrier materials like PVDC.

Yes, we are a blister mold manufacturer and support full customization.

It is designed specifically for small batch blister packaging, R&D centers, and pilot production.

Yes—Online installation guidance, video training, and operation manuals are included.

You can get a price of this model or send us any question to get any information you would like to know, we will reply to you soonest.