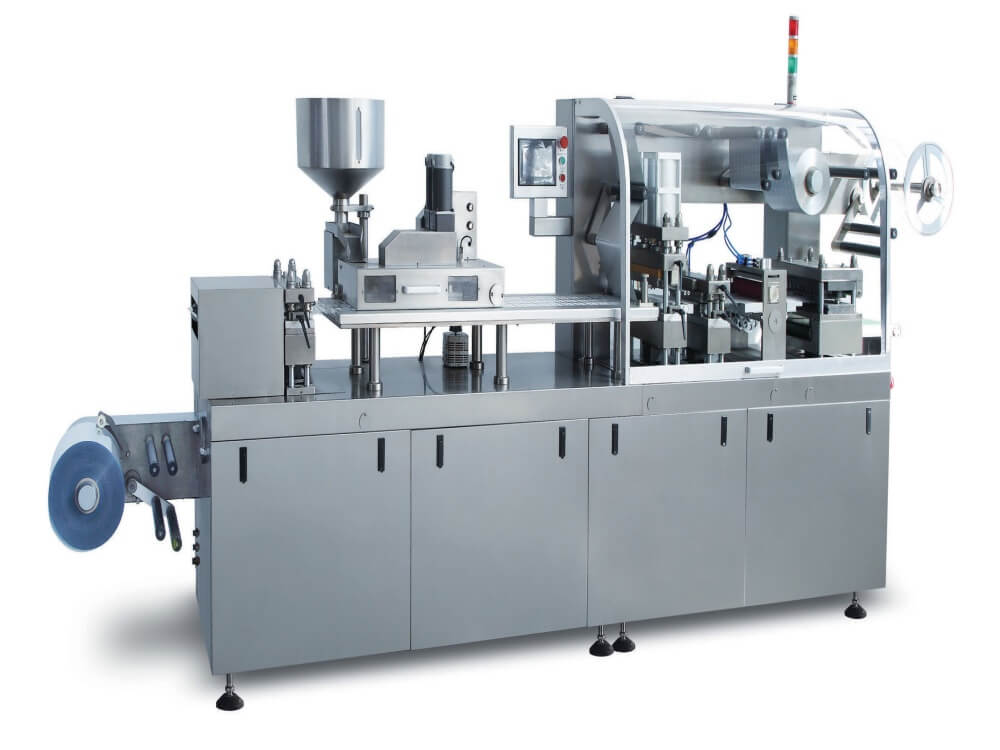

A capsule blister packing machine is a pharmaceutical packaging machine used to seal capsules into individual blister pockets made from materials like PVC, PVDC, PET, or aluminum foil.

This capsule blister packing machine is a new type of international packaging equipment developed by our company. The intelligent operation platform enables multi-variety production packaging technology. With the current technology, it can achieve coordinated, smooth, energy-saving and efficient operation at each workstation. This machine is suitable for sealing packaging of tablets, capsules, soft capsules, candies, large honey pills, injections and other items in the fields of pharmaceuticals, food, medical devices, cosmetics, health supplements and handicrafts. The equipment structure and packaging process fully comply with “GMP” requirements.

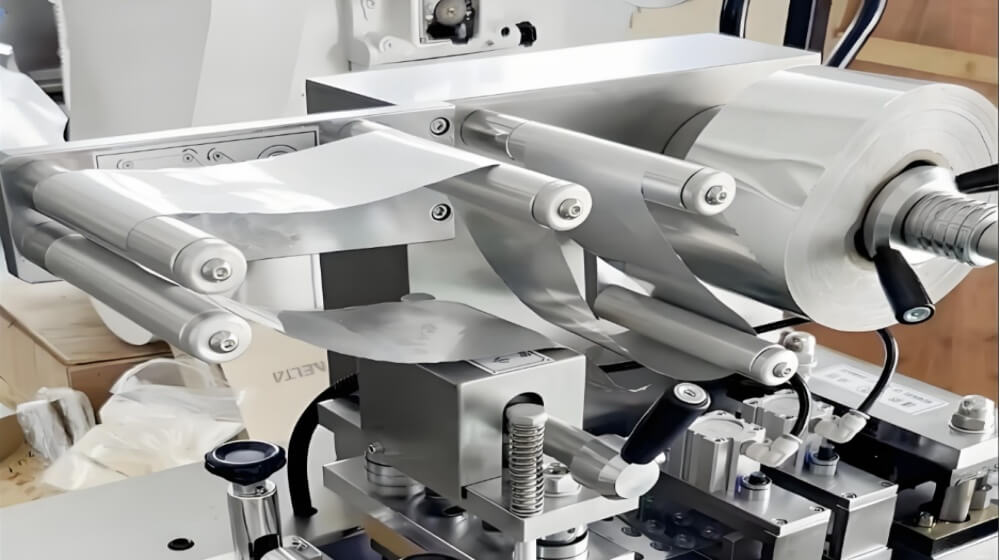

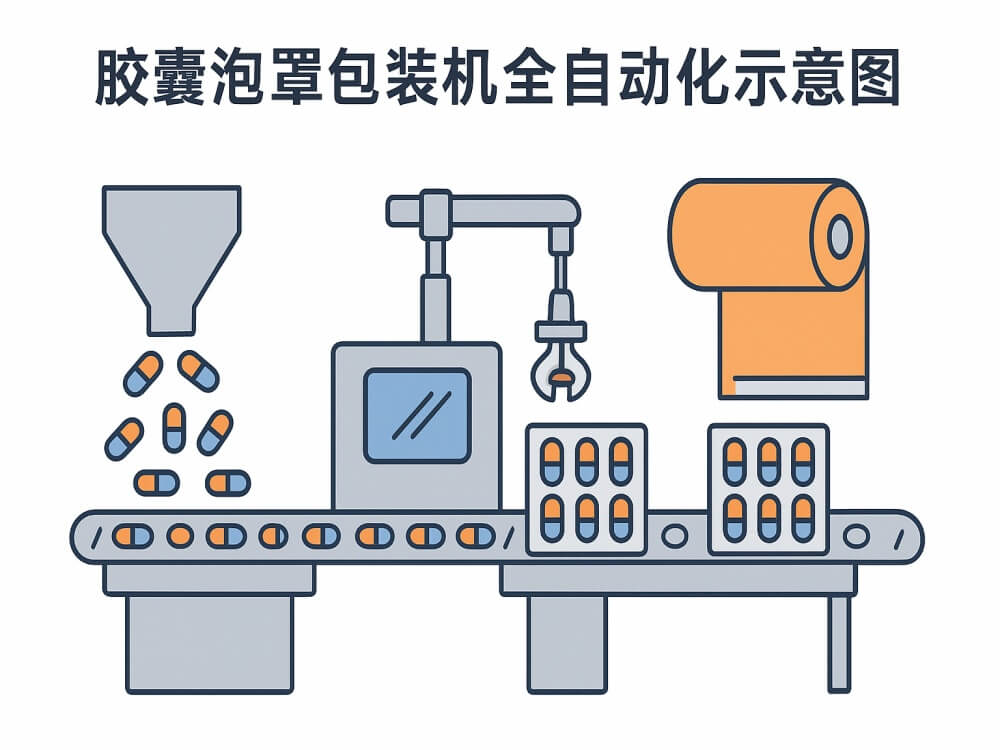

The capsule blister pack machine to fill capsules into cavities, include forming film loading station; forming working station; capsules feeding system; blister inspection system ; sealing station ; Perforation station and punching station.

If you are in this capsule blister packing business, please talk to us so we can tell you more about our machine.

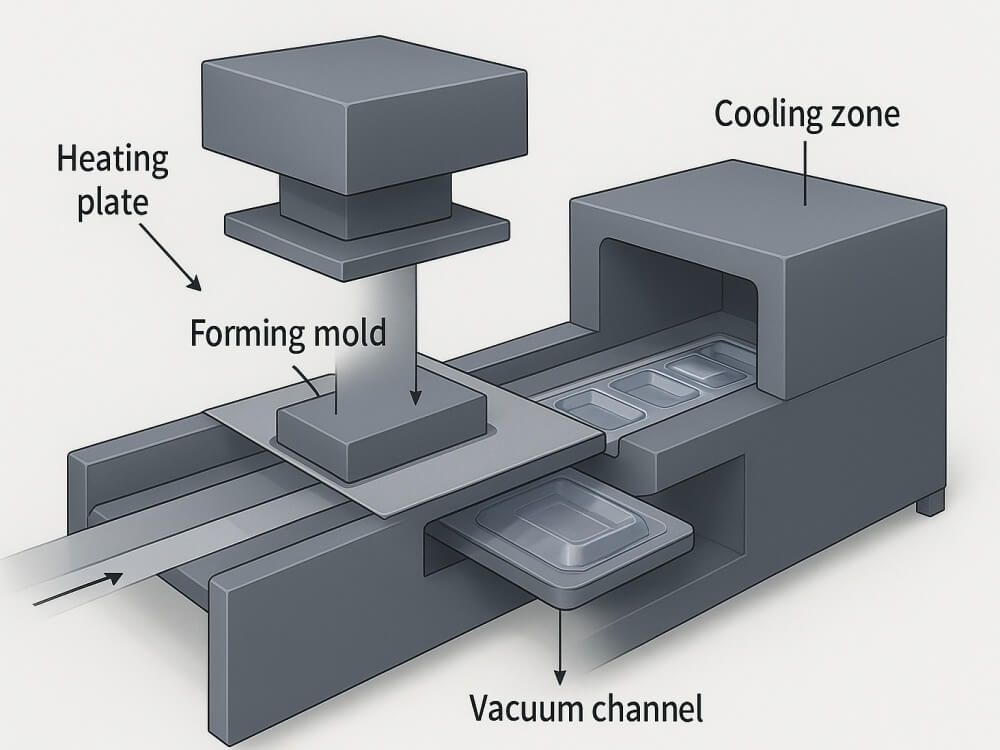

After heating the plastic sheet material (such as PVC/PET) to make it soft, individual blister cavities are formed, which are used to hold capsules.

The forming process of the blister machine mainly relies on the principle of heating and softening of thermoplastic materials → traction deformation → shaping and cooling.

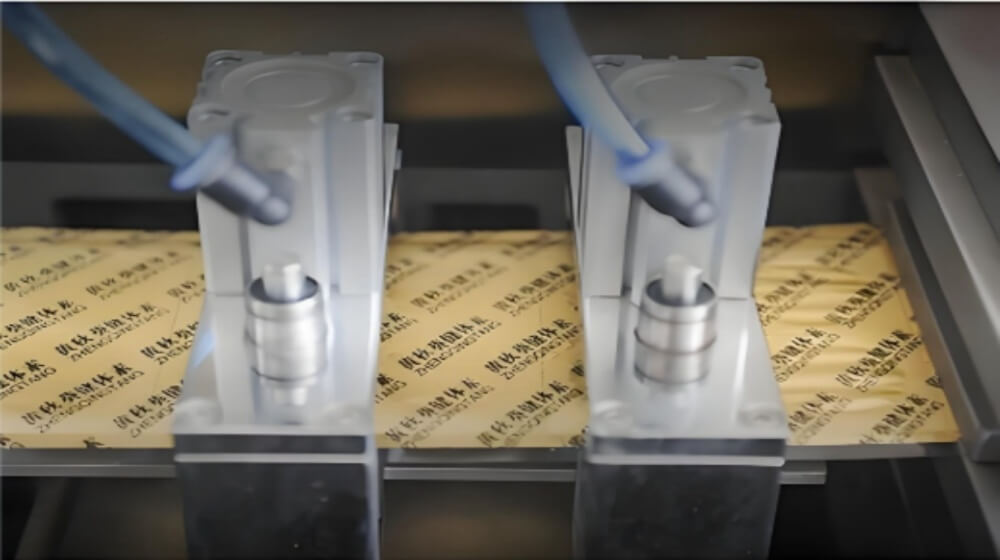

When feeding capsules into blisters, It is mainly realized by a special feeding system. Common capsule feeding methods in pharmaceutical blister packaging machine have following types: Rotary Brush Feeder, Guide Rail Feeder, Vibrating+ track combination.

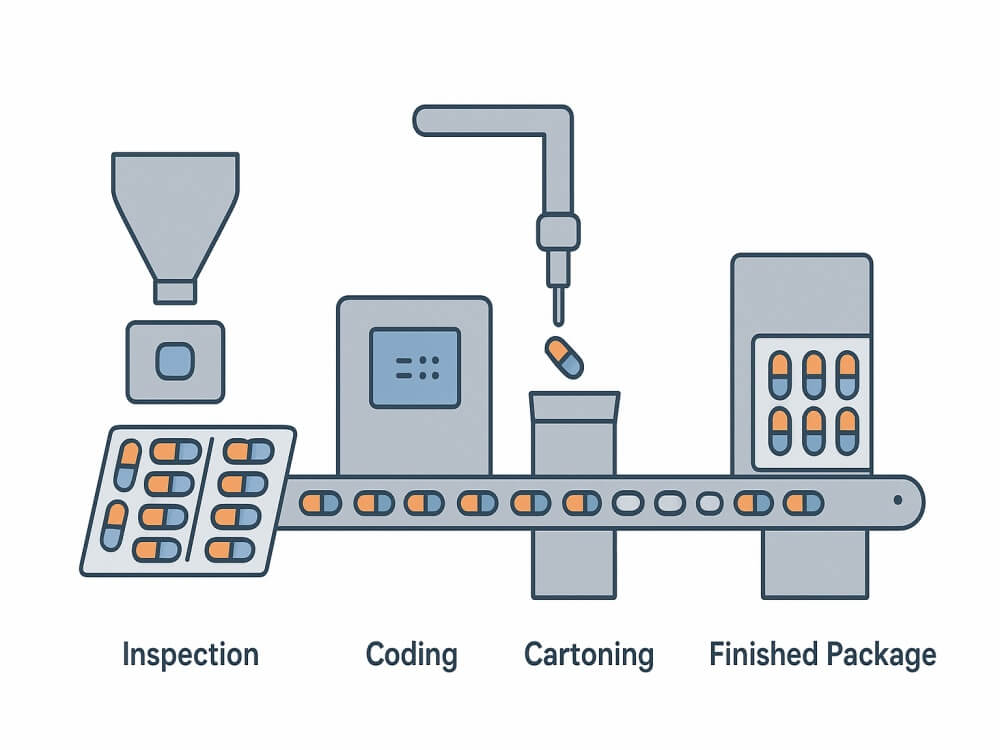

The Blister Inspection System is a vision-based quality control module that checks the quantity, location, shape, color and integrity of the product within each blister cavity for compliance with standards. The system uses industrial cameras and image analysis techniques to detect missing, broken or wrong capsules and automatically reject defective ones.

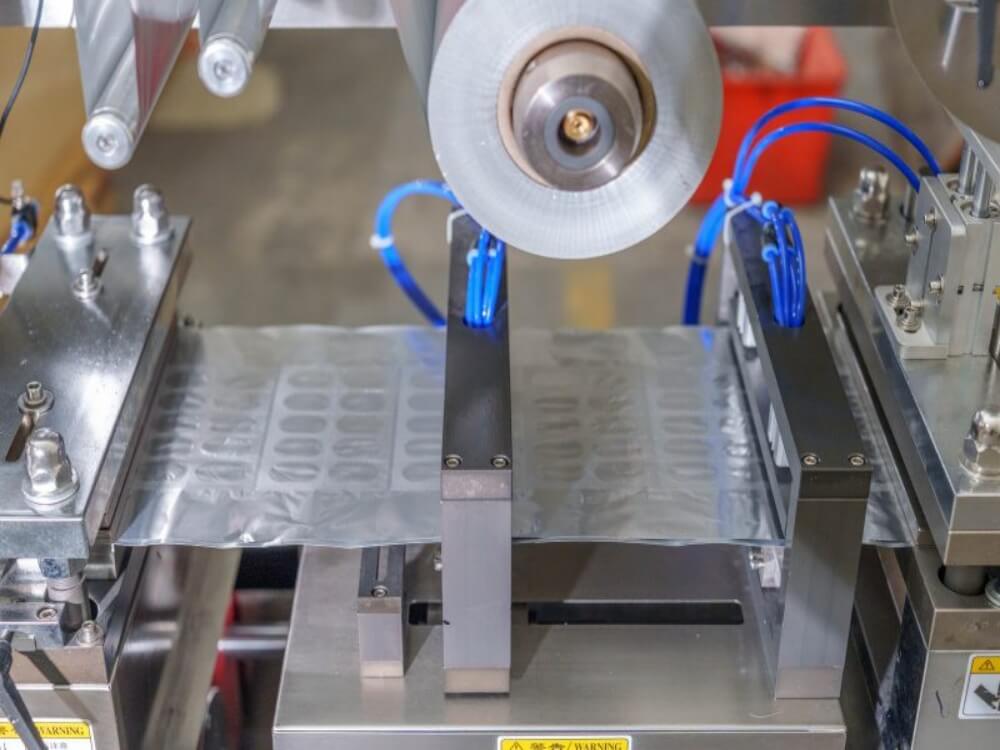

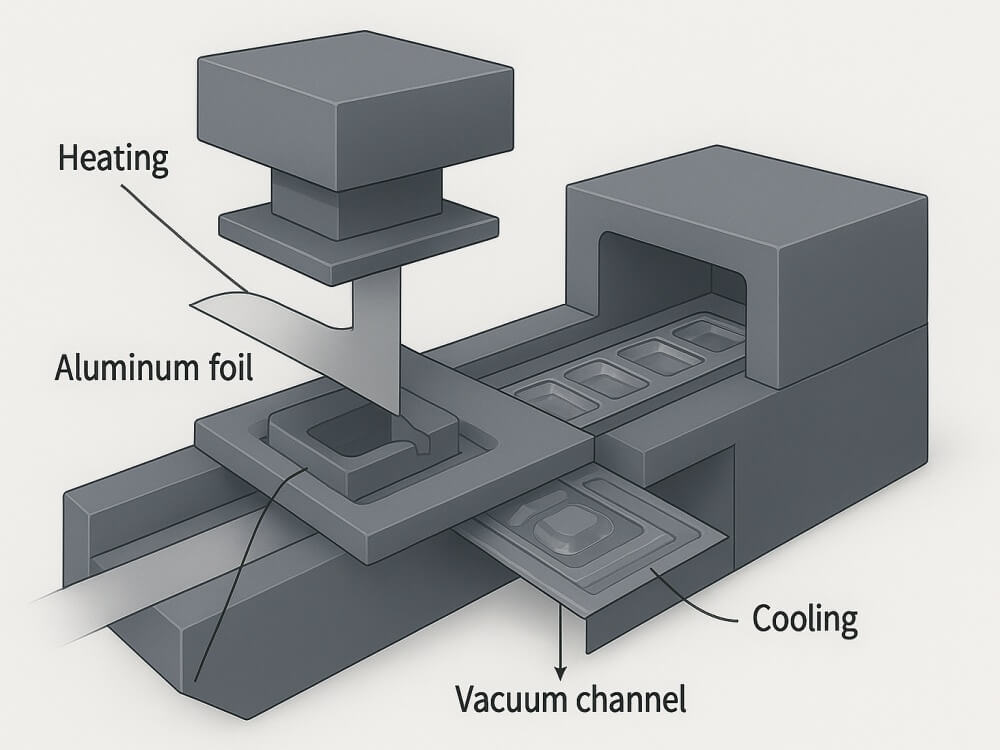

The formed plastic blister (made of PVC/PET/PVDE or Alu, etc.) is firmly sealed with aluminum foil or heat-sealing film to form a sealed packaging cavity, protecting the medicine from moisture, oxygen and contamination.

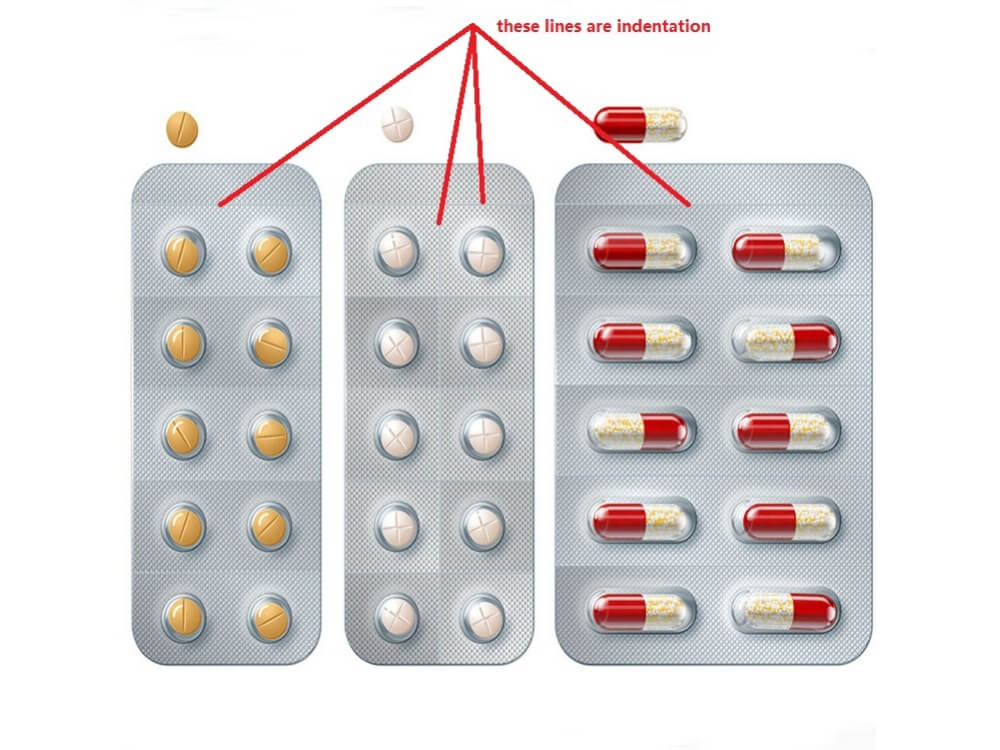

Perforation is used to create tear lines on blister packs, allowing easy separation into individual doses and improving convenience and product presentation.

Punching is the process of cutting sealed blisters into individual blister packs using precision stamping dies to ensure that the shape and dimensions of each package are consistent

According to capsules size: 0#,1#,2#, 3#, 4#, 5#, there have model DPP-80, DPP-180 & DPP-260 for your choose. If your capacity require 25-50times/min, model DPP-180 is the best choice. So as per yours to choose the models.

DPP-80 Punch frequency: 10-30 times/min.

DPP-180 Punch frequency: 25-50times/min.

DPP-260 Punch frequency: 25-60times/min.

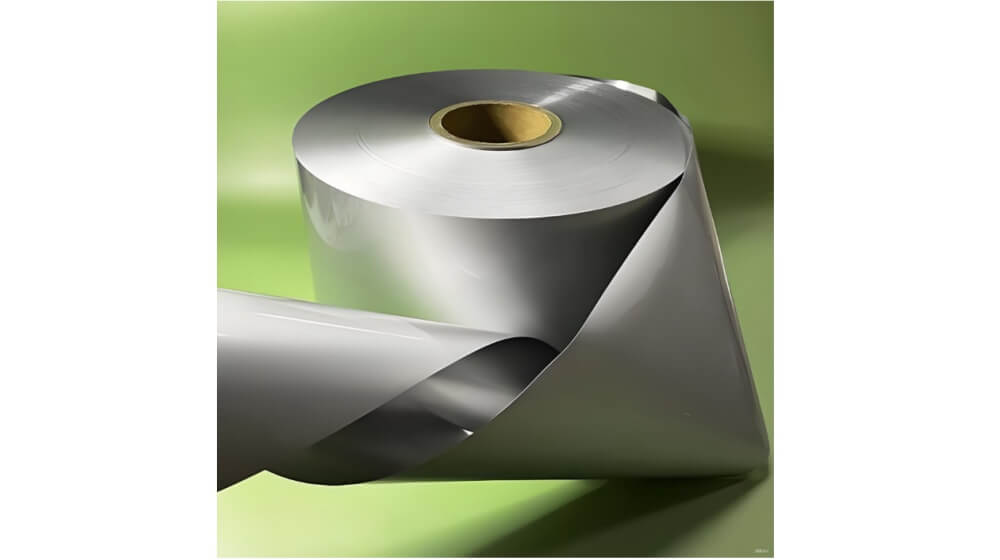

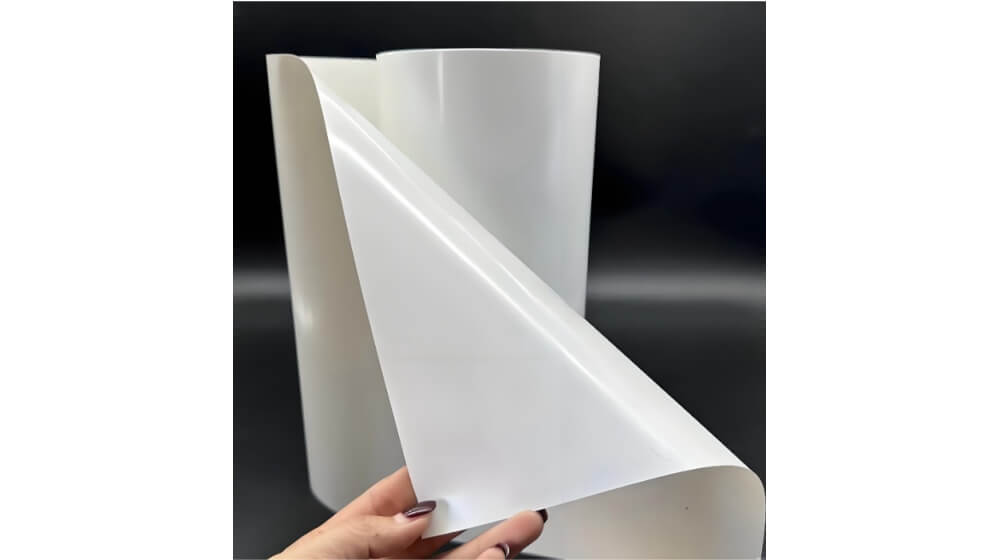

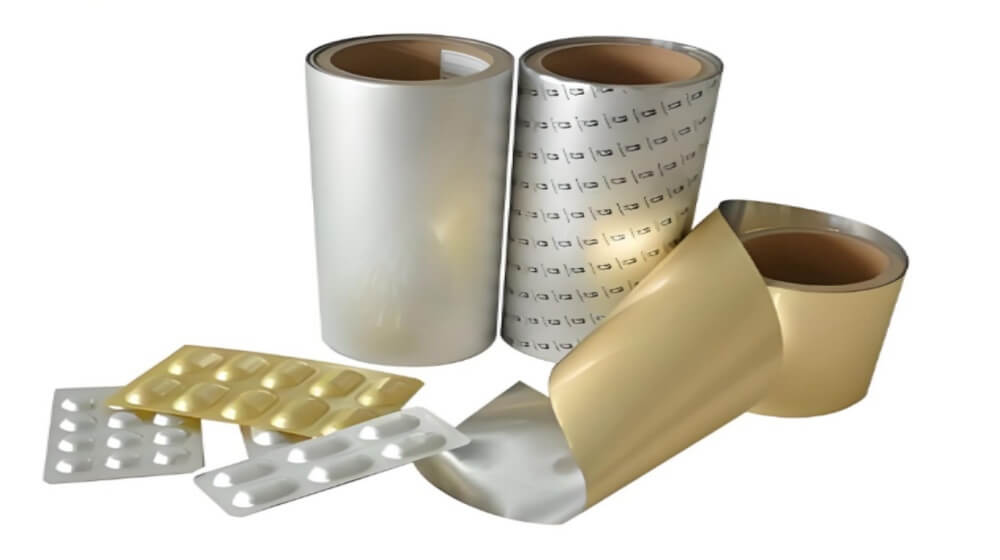

The commonly used materials for capsule blister packaging machines are mainly divided into two categories: forming film and lidding material. Different medicines choose different materials to meet the requirements of moisture-proofing, oxygen-proofing and light-shielding.

Forming film material such as PVC, PE, PET, PVDC formed to blister cavities by heating.

The sealing material is the upper layer material used for sealing the cavity in a blister packaging machine. It is usually aluminum foil or an aluminum-based composite film, ensuring the stability and safe use of the medicine, and also facilitating the easy opening and taking of the medicine.

The forming methods for plastic or aluminum. PVC, PVDC, ALU-ALU, PE, PET, different materials correspond to different heating/molding systems.

Thermoforming mode suits to plastic film, like PVC, PE, PVDC, PET. Different plastic film need different forming temperatures. Such as common PVC need 100-150℃. PVC/PVDC need 140-180℃ because of coating layer. For capsules packing, factories usually adopt PVC, the common thickness is 250–500μm.

Cold forming is applied to Alu Alu blister packing machine when forming film is aluminium foil, not heated; instead, it is formed by cold drawing with a die mold and is used for sealing.

We, as professional supplier to help customers select based on their budget and automation requirements. Fully automatic working machine.

If you are in this capsule packing business, please talk to us so we can tell you more about our machine.

For capsule packing , you can see this machine all steps automatically. “Can be integrated with cartoner for full packaging line”.

Functions Options: Encoder,Inspection, Rejection, Batch Numbers, Cartoning machine assembly connection

User-friendly HMI with multi-language interface, PLC (brand SIEMENS or OMRON) control system, servo drive.

Capsule blister packing machines designed for different user groups, such as Pharmaceutical Industry, Nutraceutical / Health Supplements, Cosmetic Industry etc.

The blister packaging machine is widely used in the pharmaceutical, nutritional, medical device, food, cosmetic and electronic industries. It is suitable for moisture-proof, sealing and display packaging of single pieces, single doses and small items.

The blister packaging machine is mainly used for the unit-dose packaging of solid preparations, ensuring the stability, safety and traceability of the drugs during storage, transportation and use.

For hard capsules, softgel, soft capsules, liquid capsules, Capsule Blister Line, blistering machine in pharmaceutical industry.

Soft capsules and liquid preparations, vtamin soft capsules, oil capsules, resistant to damage and oxidation

Precise drug delivery, convenience of drug protection and stability, anti-counterfeiting and tracking, in line with the GMP control standards of pharmaceutical factories

The blister packaging machine is mainly used in the health supplement industry for single-dose packaging of solid-form health supplements, such as capsules. It achieves product moisture-proofing, oxygen-proofing, and pollution-proofing through efficient and automated packaging, and is also convenient for consumers to take the products according to the dosage.

Blister packaging is one of the mainstream packaging forms in the health supplement industry, and it is particularly suitable for fish oil, lecithin, other oil-based capsules, softgel, vitamins Soft capsules.

Cosmetic Samples: capsule essence,Cosmetic Sample Blister Machine.

The blister packaging machine is mainly used in the cosmetics industry for the sealed and quantified packaging of small-dose, easily contaminated, and high-value-added products. It achieves product unitization, hygiene protection, and exquisite display through transparent or aluminum-plastic blister packaging.

It is rapidly expanding from the pharmaceutical industry into the beauty and personal care sectors, and is particularly suitable for:

High-end skin care products; Single-dose beauty essence; Facial Essential Oil Capsules; Travel-sized & trial-sized packaging.

The blister packaging machine is not only a core equipment in the pharmaceutical industry, but is also widely used in the food industry. Blister Packing Machine are also used in Food industry, for such as candy packing, chewing gum packing, mint blister packing, etc. As They are critical for packing as it will need to avoid air, also some of them need to packed separately, individually. For example, candies, because these need to be kept tightly sealed and easy to eat one by one, they are very suitable for our blister packaging machine.

We are capsule blister packing machines manufacture, there are many types of machines as per capacity you required to choose suitable one. Different machines but blister standard plate size is ALU-PVC: 80x57mm; ALU-ALU: 90x70mm. Single-capsule, double-capsule. Single-row, double-row.

Our machine has a flat plate structure with a horizontal layout. The material is transported horizontally and the blister is fed from the side. This is the mainstream product of pharmaceutical industry, high stability. Use proper sealing. If used in large-scale production line, installation and transportation are very convenient.

The machine can be designed as a split structure, the forming area and the sealing area are independent of each other for easy maintenance and cleaning.

If you are in this capsule blister packing business, please talk to us so we can tell you more about our machine.

One model capsule blister packing machine meets different products to change the molds. Suits to different specification & blister shape (round, square, irregular shape or heart). Also different forming film material PVC, PE, Alu.The machine equip with Quick-change tooling system for you to easy change the mold.

We have developed mini model machine DPP-80, standard model DPP-180, DPP-260 and large DPP-350 for you. As per your factory space and capacity required, you can choose a appropriate one.

As a professional source manufacturer of capsule blister packaging machines, YABO Machinery specializes in designing and producing high quality machines for the pharmaceutical, healthcare and cosmetic industries and so on. Our Capsule Blister Packing Machine represents YABO’s commitment to precision engineering, customization and reliability. With its customized designs, flexible molds and intelligent control system, not only for small volume production, clinical trials and R & D packaging projects but also for the mass productions.

Each machine is built and tested in-house to ensure consistent performance, stable seal quality and long service life.Choosing Yabo means working with direct manufacturers for better technical support, competitive pricing and full customization service from design to delivery.

You can get a price of this model or send us any question to get any information you would like to know, we will reply to you soonest.