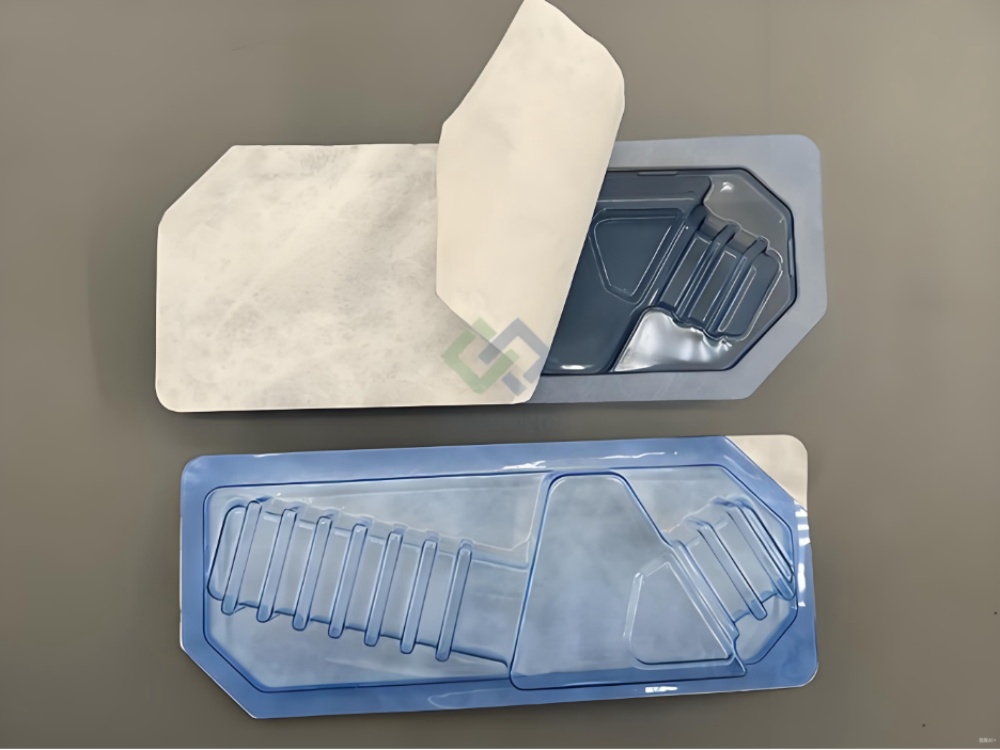

The fully automatic blister packaging machine is a dedicated equipment for aluminum-plastic composite sealing packaging. It combines product and packaging personalization, and can customize molds according to the shapes desired by customers, reflecting product diversity and meeting the shape requirements of packaging products for different customers. The available material range includes PVS, PET, HIPS, GPPS, and other plastics.

Blister packaging machines are widely used in pharmaceutical, food and medical equipment industries, tablets, snacks, syringes and other products. They have the advantages of moisture-proof, aseptic environment and preservation. They match GMP certified standards and support for custom packaging to meet multiple industry requirements for seal protection and portability.

It is used for the packaging of tablets, capsules, suppositories and ointments in pharmaceutical factories, health care companies and pharmaceutical preparation rooms of medical institutions. Moisture-proof, pollution-proof and accurate dosage, in accordance with GMP certification.

Used for food processing plants, snack brands, e-commerce food sellers, candy, chocolate, nuts, freeze-dried food preservation, providing anti-oxidation packaging, easy to carry.

Used for sealing packaging of products such as wet wipes, cotton swabs, cosmetic samples, toothpaste strips, etc. for daily care brands, beauty companies, and baby care product factories. It is leak-proof, disposable, and suitable for travel.

It is used for blister packaging of electronic component factories, home appliance manufacturers, and accessory suppliers for products such as resistors, capacitors, chips, and connectors, serving the functions of anti-static, shock-proof and precise positioning storage.

The blister packaging machine speed according to the size of the product, shape to customize the mold and equipped with the appropriate feeder. The bigger the product, the slowest feeding speed, on the contrary, the smaller the product, the faster. The automatic feeding speed is faster than that of products requiring manual feeding, such as medical devices, irregular articles, etc.

About 1,500pcs/hour

About 1,200pcs/hour

About 1,000pcs/hour

It is suitable for blister packaging, sealing and coding of products such as food, medicine, mouthwash, injections, stationery, hardware, electronics, auto and motorcycle parts, daily necessities, cosmetics, health care products and so on.

The PET film protects heavy and sharp products (such as hardware and medical devices), and can resist tearing and puncturing to protect the inner products. It has high mechanical strength and is not prone to damage during transportation and storage.

High transparency, clearly presenting the product shape, with excellent visualization effect, enhancing the product’s recognizability. Suitable for blister packaging of food, toys, small hardware accessories, etc.

The low price of raw materials is conducive to cost control. The production cost is highly cost-effective, making it suitable for mid-to-low-end products and large-scale general blister packaging.

Main function | PET, PVC, HIPS, GPPS and other plastic bubble cover products automatic forming ,heat sealing, spraying ,punching |

Scope of application | Widely used in PET /PVC/HIPS and other plastic blister,food/hardware/daily use/medicine/electronic components/health care products and similar materials for blister sealing packaging |

Punches Frequency | 12-25cycle/min |

Material | PVC PET HIPS PLA |

Max. Forming are | 330*240mm (L*W) |

Max. Forming depth | 46mm |

Air consumption | >0.3m3/min |

Total power | 4kw |

Mould cooling | Tap water or recycling water, 60L/H |

Overall dimension | 4750*900*1800mm(L×W×H) |

Weight | 2500kg |

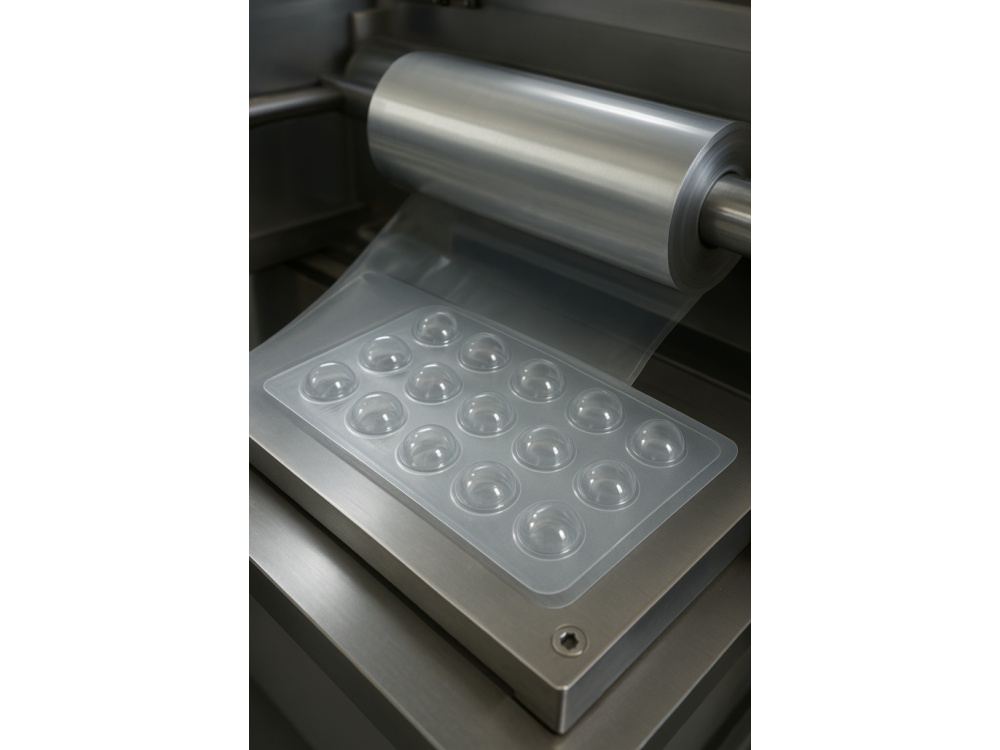

→Film Unrolling → Plastic molding → Adding materials → Heat sealing → Ink-jet marking → Product cutting → Finished product output → Waste material winding

Unique design ensures more stable feeding. Need feeding structure detail information, get touch now!

The blister forming process uses a combination of mechanical stretching driven by a cylinder and positive pressure blowing to ensure a uniform thickness, stronger and more attractive cavity.

Using servo motors for traction ensures a more stable movement. The dimensions of the four sides of the plate are basically the same.

Servo motor is used traction, the movement process is more stable, and the dimensions of the four sides of the plate are basically the same.

This hardware knife is made of a special die steel that has been hardened. It is accurately machined by the machining center to ensure the durability of the cutting edge.

The waste collection device of the blister machine can automatically collect the remaining material of the film, thereby reducing material waste and preventing the equipment from sticking.

BH-350A blister packaging machine is reasonable, with the characteristics of high automation, simple operation and simple design. It runs smoothly, has low noise, compact structure, saves space and is easy to maintain. It is suitable for automatic feeding products such as medicine and food, as well as manual feeding of irregular parts. It has good sealing and moisture-proof performance, conforms to GMP requirements n. It supports mold replacement and linkage production, high efficiency, material saving, but also can detect and eliminate unqualified products to meet the needs of multi-batch production.

Electrical control system: All major electrical components are of imported brands. PLC computer control system, variable frequency speed regulation, reduce noise, improve machine operation stability.

Optimize the mold structure to be suitable for large-scale production and reduce the machine adjustment time. Design the number and arrangement of the cavities as needed to reduce material waste. Customize unique blister shapes to achieve brand differentiation.

After-sales service is available both online and offline. Cooperate in guiding the factory for on-site installation and commissioning. Provide the necessary spare parts on time.

You can get a price of this model or send us any question to get any information you would like to know, we will reply to you soonest.