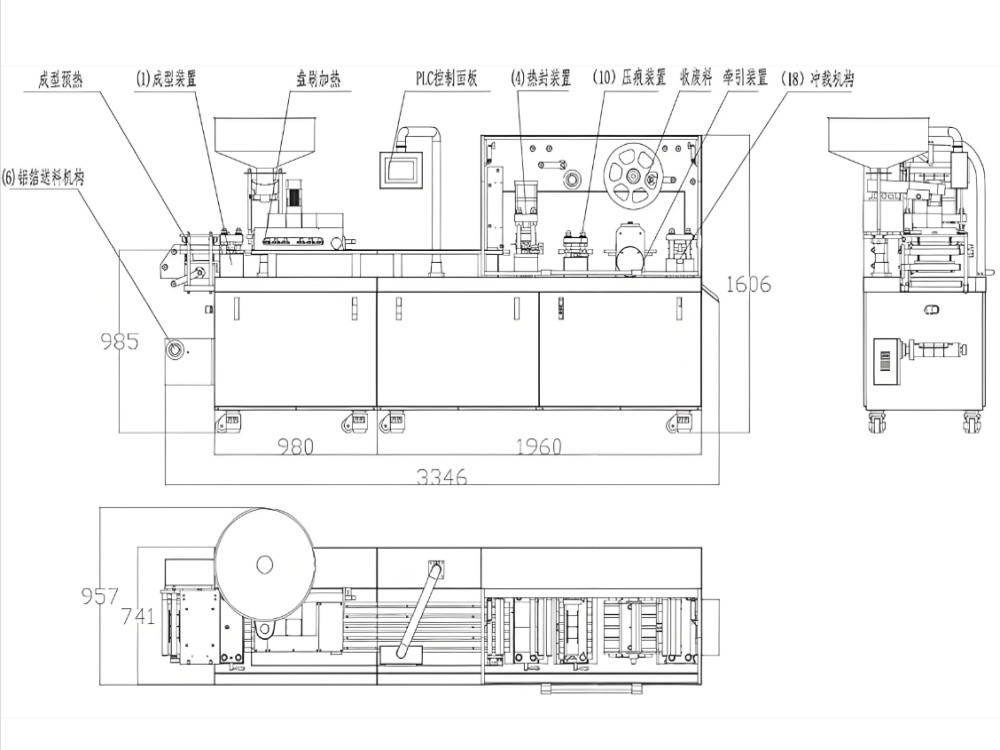

The Blister packing equipment is a high-speed, servo-driven fully automatic blister pack solution engineered for pharmaceutical, healthcare, and consumer industries. Ideal for large-volume continuous production, it offers a wide forming area, precise motion control, stable sealing performance, and fast changeover.

It is the ideal machine for tablets, capsules, softgels, ampoules, vials, syringes, medical devices, and various solid products that require safe and hygienic blister packaging.

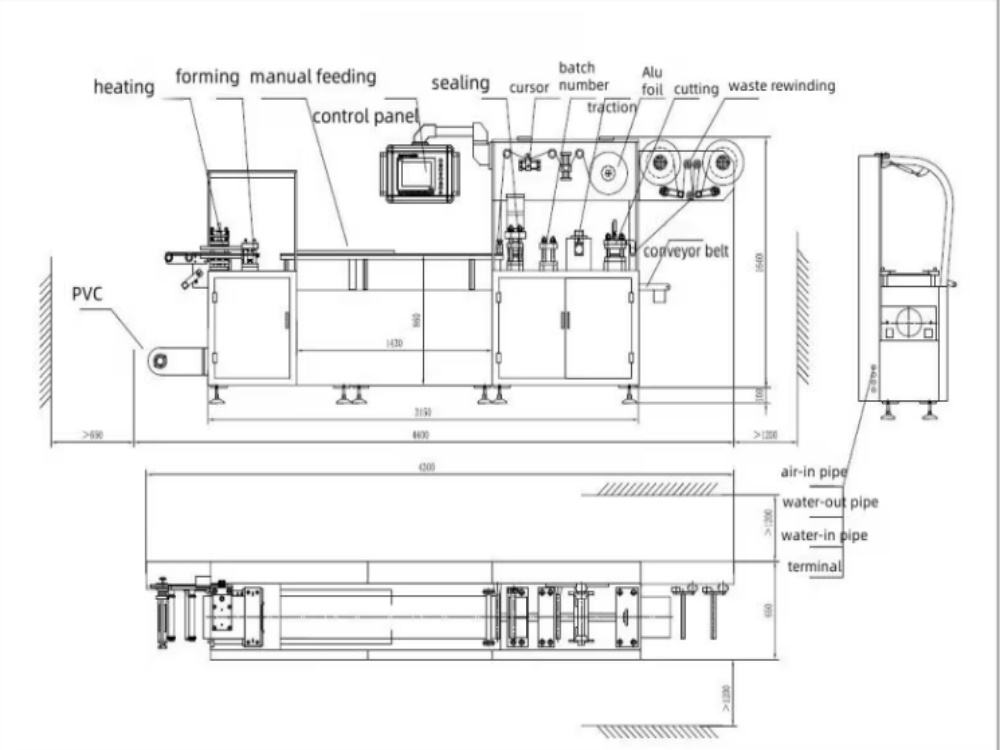

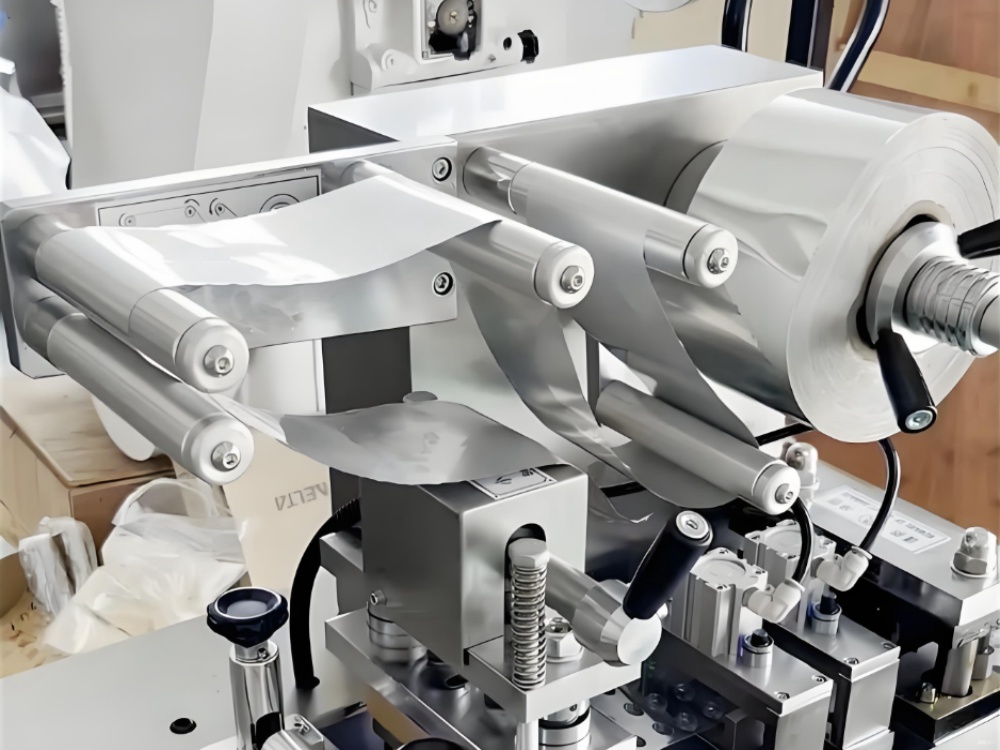

The blister packaging machine integrates the entire process from film feeding (such as PVC, PET, PE, etc.) to heating, forming, feeding, heat sealing, batch number printing, embossing, and cutting, all in one stop. Fast speed, suitable for large-scale product production in pharmaceutical factories, food factories and irregular products to save labor cost much.

The blistering pack equipment is a new type of international packaging equipment developed by our company. The intelligent operation platform enables multi-variety production packaging technology. With the current technology, it can achieve coordinated, smooth, energy-saving and efficient operation at each workstation. The equipment structure and packaging process fully comply with “GMP” requirements.

The main body of the whole machine is made of 304 stainless steel, complying with the requirements of GMP standard. This stainless steel has sufficient durability to enable DPP 350 blister packaging equipment is robust and durable, to ensure long-term production stability, not easily damaged.

Our high speed DPP model 350 blister packing equipment can produce a variety of shapes and sizes of mold according to customer requirements.

Depending on your production needs, you have the flexibility to switch to produce different products.

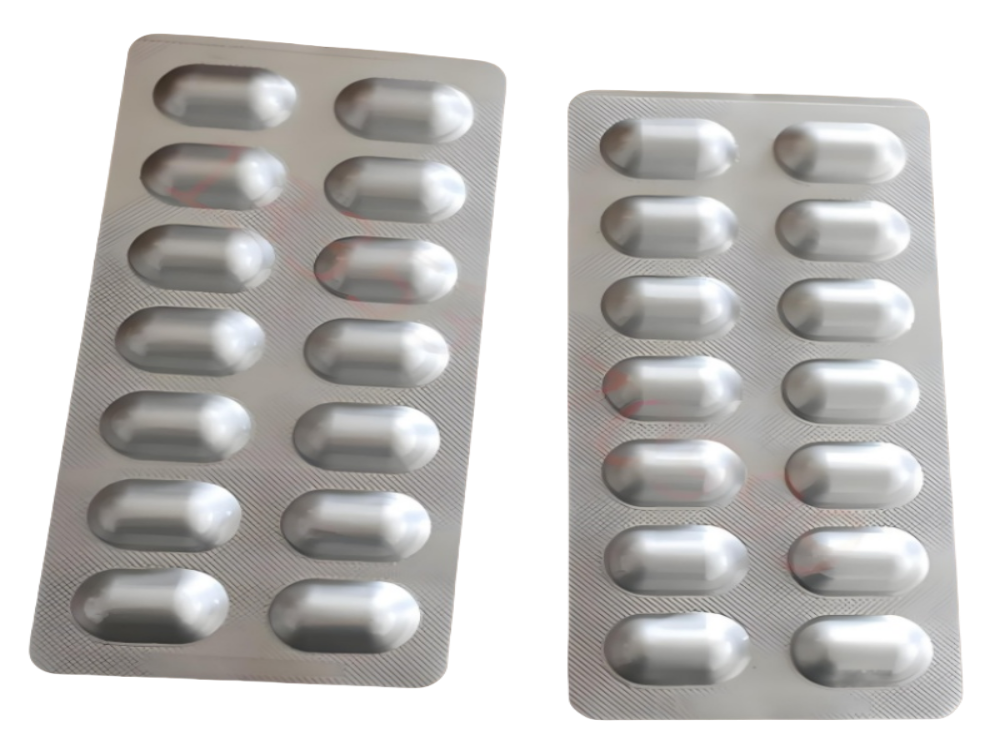

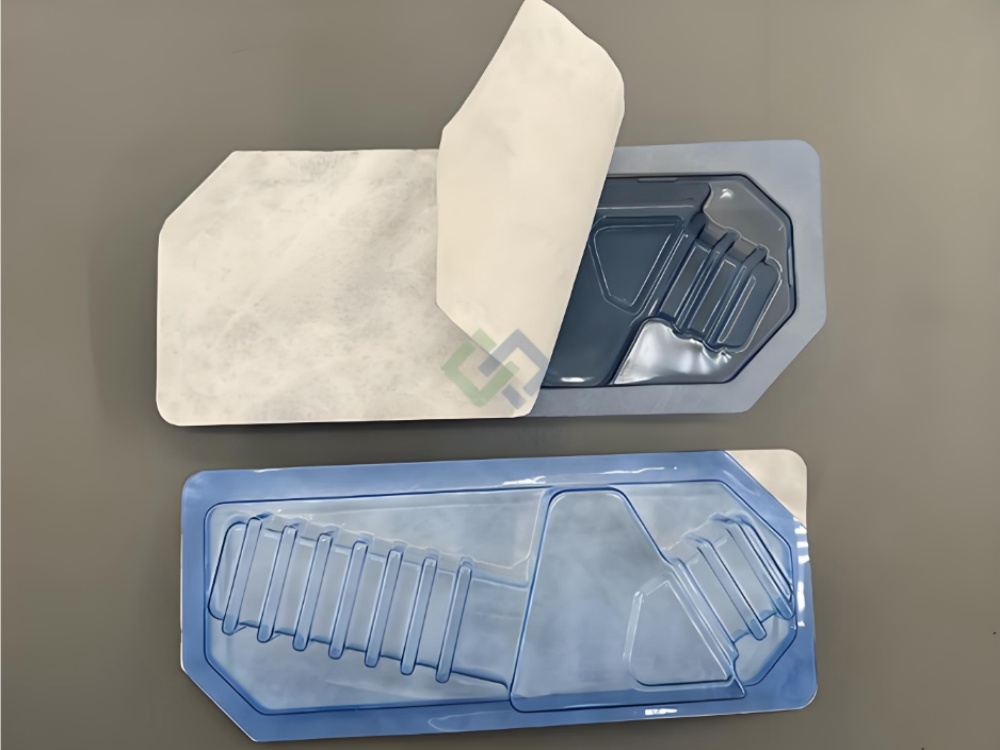

This machine can be used for both aluminum-plastic, aluminum-aluminum and plastic-paper production. Regular products (capsules, pills, candies, honey pills, tablets), irregular products (tools, gifts, medical device, toys), the machine can meet all.

High capacity automatic Blister Packing equipment with a wide range of applications, not only in many industries but also apply for different packaging material requirements. Different packaging industries require different materials, some need plastic-aluminum film, some need aluminum-aluminum film and some plastic-paper film. The DPP 350 Blister Packing equipment is a machine that can support almost all materials used in blister packaging on the market, including alu PTP, PVC, PET, PE, and PVDC materials.

Aluminum and aluminum cold press forming is a kind of forming process without preheating. This forming process does not affect the heat-sensitive drug. It is suitable for non-standard deep cavities and special shaped pills and ensures that the shape of each cavity remains the same.

PVC has high transparency and can clearly display the appearance of products such as capsules, soft capsules, tablets, chocolate beans. PVC is sensitive to heat and softens quickly after heating, which is favorable for high-speed continuous forming and improves the production capacity.

PS is cheaper than PVC. It is suitable for packaging non-pharmaceutical items such as toys, hardware tools and electronic components. During thermoform process, PS can soften evenly and form a deeper bubble cavity, so be suitable for irregular shaped products. With strong strength not easy to deform.

Plastic film unwinding→ Heating → Forming → Product feeding (brush feeder / guide rail/ manual → Vision check → Heat sealing with aluminum foil → Batch coding / printing→ Perforation → Punching → Finished blister output

This machine is suitable for sealing packaging of tablets, capsules, soft capsules, candies, large honey pills, injections and other items in the fields of pharmaceuticals, food, medical devices, cosmetics, health supplements and handicrafts. The equipment structure and packaging process fully comply with “GMP” requirements.

This blister packing equipment is highly suitable for large-scale pharmaceutical mass production. If you need blister pack equipment to pack your medicines or tablets, contact us and customize the molds you need.

High-speed blister packing equipment can be used for packaging solid foods such as biscuits and snacks, as well as single-dose liquid syrup, olive oil, honey, and other liquid or semi-fluid foods. Custom designs according to the characteristics of the food and packaging needs.

The blister pack equipment with waterproof, anti-pollution, portable advantage, suitable for various forms of nutritional supplements, especially suitable for products with small doses and long-term storage requirements. Such as vitamins, calcium tablets, DHA gel candies, etc.

Blister packing equipment for various electronic components and hardware products, such as resistors, capacitors, chips, sensors, micro batteries, etc. Custom mold designs according to the size and shape of products to ensure not damaged during transportation.

Blister packaging equipment can be used to pack some small medical devices, such as disposable syringes, acupuncture needles, etc. It can provide excellent sealing, effectively block bacteria, dust, and moisture, and meet the standards for medical device packaging.

Blister packaging equipment is designed for large pharmaceutical or health product manufacturing plants. The machine runs at 25 to 60 times per minute. Production rates vary depending on packaging materials and product specifications. In short, balances precision, efficiency, and flexibility, making it ideal for large-scale blister packaging needs.

PVC/Alu thermoforming: approx. 2,500-3,600 blisters/hour.

Alu/Alu cold forming: approx. 2,000–3,000 blisters/hour.

Feeding by hands: approx. 1,500-2,000 blisters/hour.

Punches Frequency | 25-60times/min |

Production capacity | 6000-14000pcs/hour |

Max. Forming depth | 20mm, customized |

Stroke travel range | 30-120mm, 140mm customized |

Total power supply | 380V 50Hz 8.5kw |

PVC hard film | 0.25-0.5×350 mm |

Dialysis paper | 50-100g×350mm |

PTP Aluminum film | 0.02-0.035×350mm |

Mould cooling | Tap water or recycling water |

Overall dimension | 4460*860*1620mm |

Weight | 2150kg |

Blister packing equipment can be customized for you with so many advantages. The main unit has overload protection, PVC and PTP packaging material level detection, automatic fault diagnosis, and automatic shutdown protection functions. The safety performance is high.

The flat plate structure can package products with special shapes, such as round, square, and triangular regular products. Liquid, paste, and syringe with a liquid feeder and irregular products feeding by hand. The entire feeding, forming, heat sealing, batch number and cutting process can be completed automatically and continuously.

The PLC programmable control and touch screen from Omron, along with Panasonic brand servo motors for traction, allow for the adjustment of the traction length within the technical parameters range through the touch screen program. This reduces packaging materials and time consumption.

Vibrating type feeder , ensuring the stability and uniformity of the vibration, which guarantees the safety and integrity of the items. The discharge and material level detection and control of the hopper, as well as the reduction of long-term friction of the material, ensure the integrity of the material.

Adopts a quick-installation structure design, suitable for multi-variety production. The replacement of molds is more convenient and effective (it only takes 30 minutes to change the molds and start adding materials for production).

Special processing and assembly techniques are used to ensure the balanced operation of the aluminum foil without deviation or shaking, promoting more accurate and stable image alignment.

It has an automatic waste collection system, which collects waste materials evenly, outputs finished products orderly, equip a conveying belt on output port , providing necessary conditions for following equipment and production.

This machine can be used for both aluminum-plastic and aluminum-aluminum production.The entire machine adopts a split connection design, easy transportation and entry into elevators and workshops.

You can get a price of this model or send us any question to get any information you would like to know, we will reply to you soonest.