The blister pack packaging machine model DPP 180 is a compact, efficient, and cost-effective solution for forming, sealing, and cutting blister packs for tablets, capsules, softgels, pills, and small medical devices.

Engineered for pharmaceutical, nutraceutical, and healthcare packaging, this machine delivers stable forming quality, fast changeovers, and low material waste—ideal for factories requiring mid-volume blister packaging with strict GMP compliance.

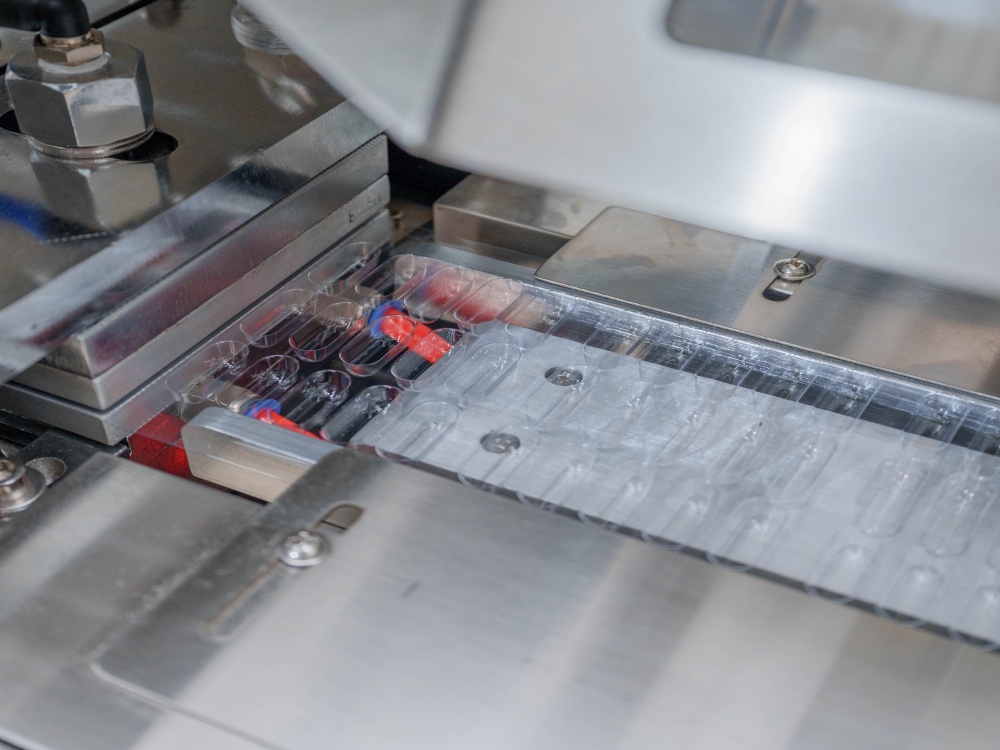

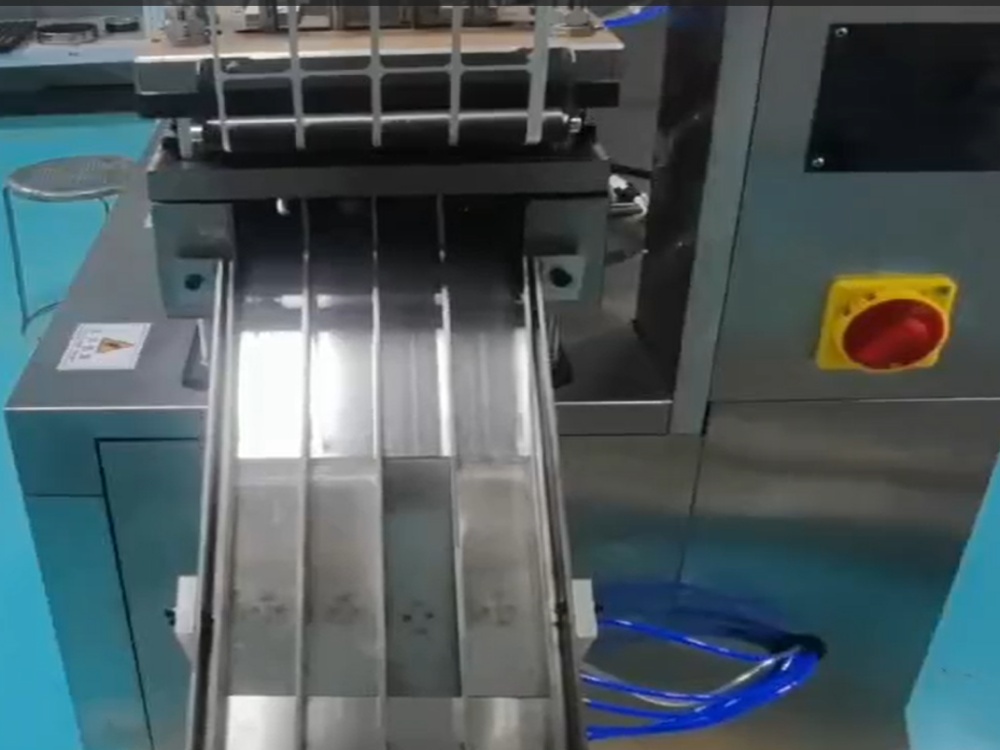

This video shows how the Alu alu blister pack machine works, from Alu film delivery, Alu forming, tablets feeding, heat sealing, servo traction, cutting, and punching. Alu PVC is also available.

The Blister Pack Packaging Machine balances speed, precision, and cost, making it one of the most reliable and economical blister machines in the global packaging market. Ideal for pharmaceutical factories, health supplement brands, R&D pilot lines, and contract packaging companies seeking reliable blister packaging performance at an affordable cost.

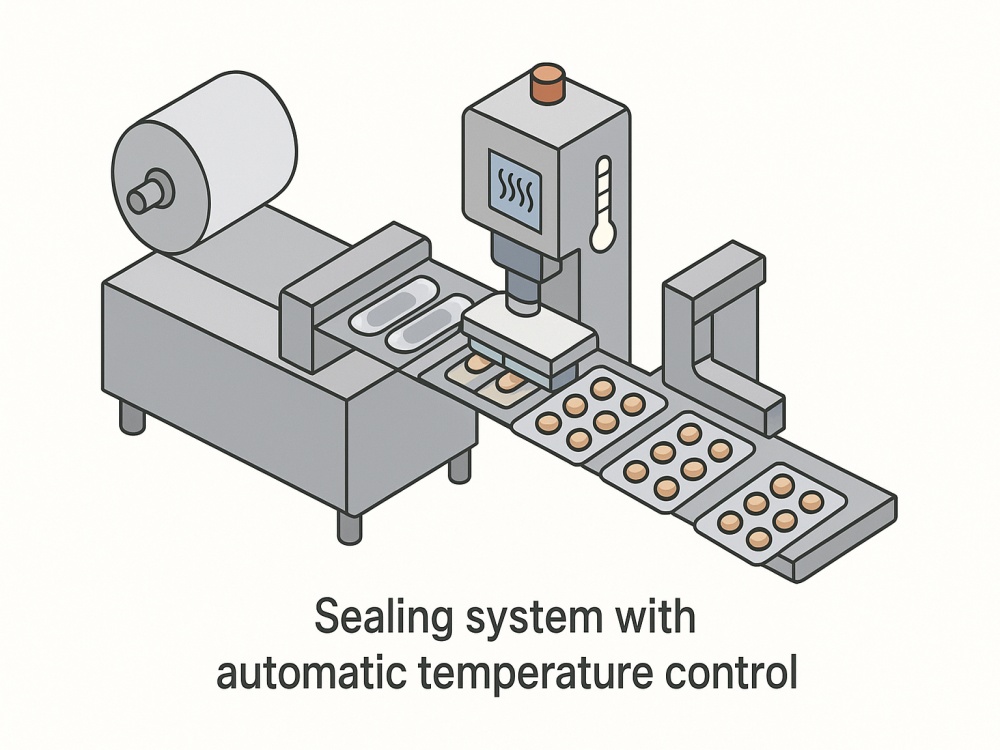

Pharmaceutical and nutraceutical companies increasingly require flexible DPP 180 blister pack packaging machine that supports frequent product changes, lower batch sizes, and higher material efficiency. The DPP 180 is designed to solve these problems by offering:

Even for deep cavities, it is suitable for pharmaceutical grade blister packaging, such as tablet blister packaging, capsule blister packaging, pill blister packaging. Uniform heating and shaping ensures consistent shape of blister cavity to protect fragile tablets.

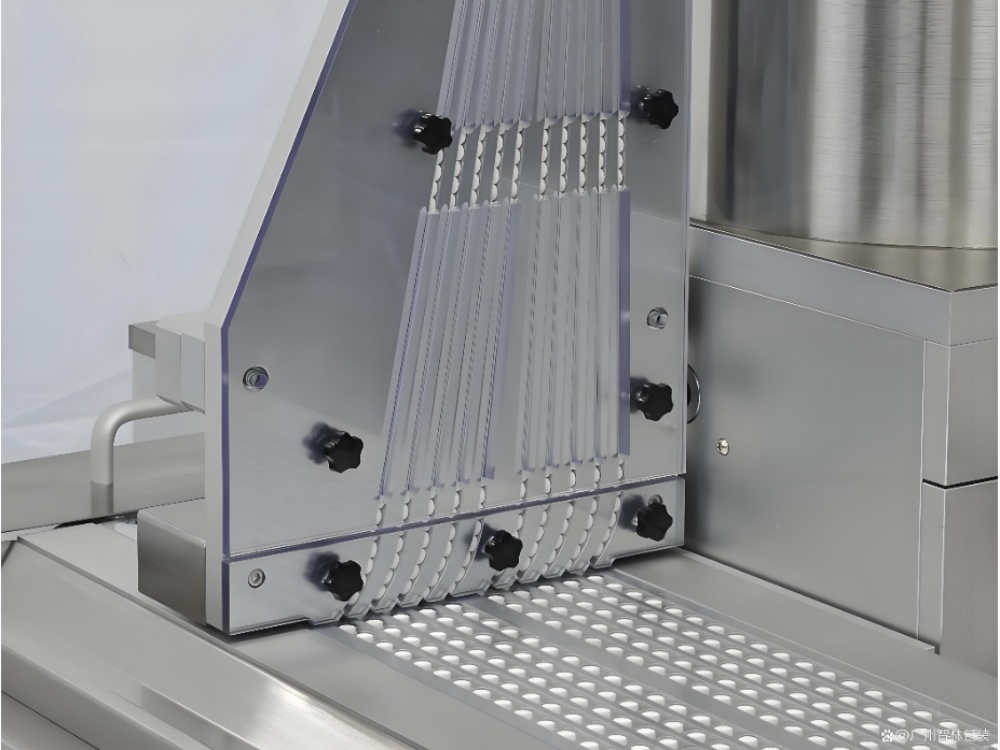

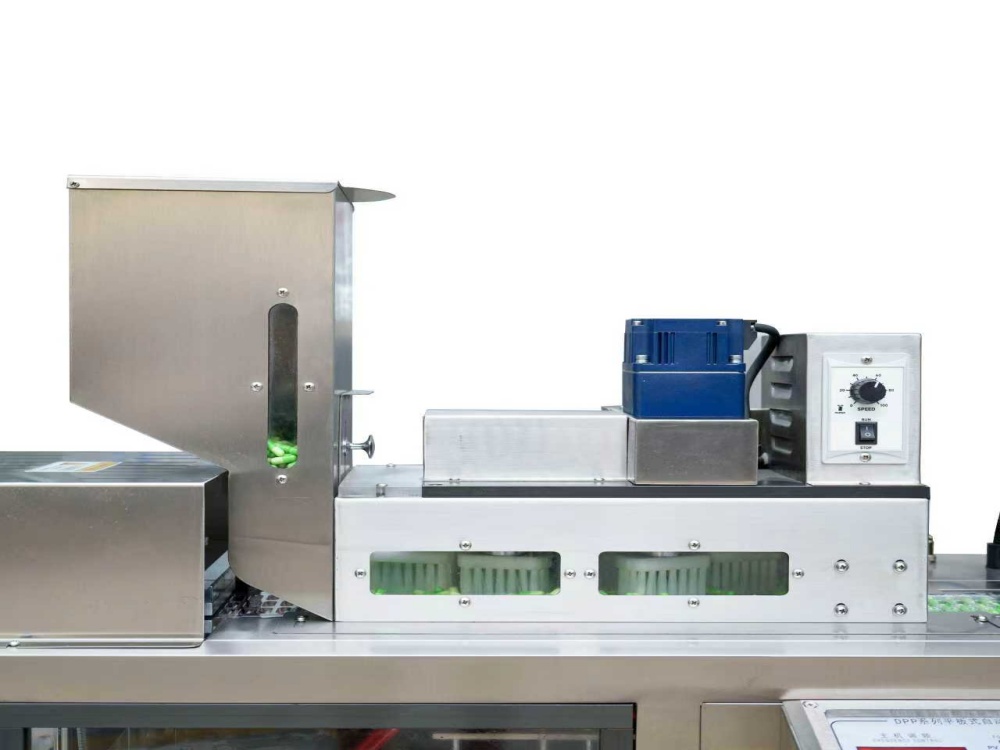

According to different products, corresponding feeding systems: tablet feeder, capsule feeder, brush feeding, vibratory feeder, and medical tray feeders are available equipped to ensure precise feeding for each product.

The heating, forming, sealing and punching stations ensure consistent blister quality, uniform blister shape and accurate sealing temperature control. In order to prevent sealing weakness, ensure sealing stability, avoid “sealing leakage” and sealing defects.

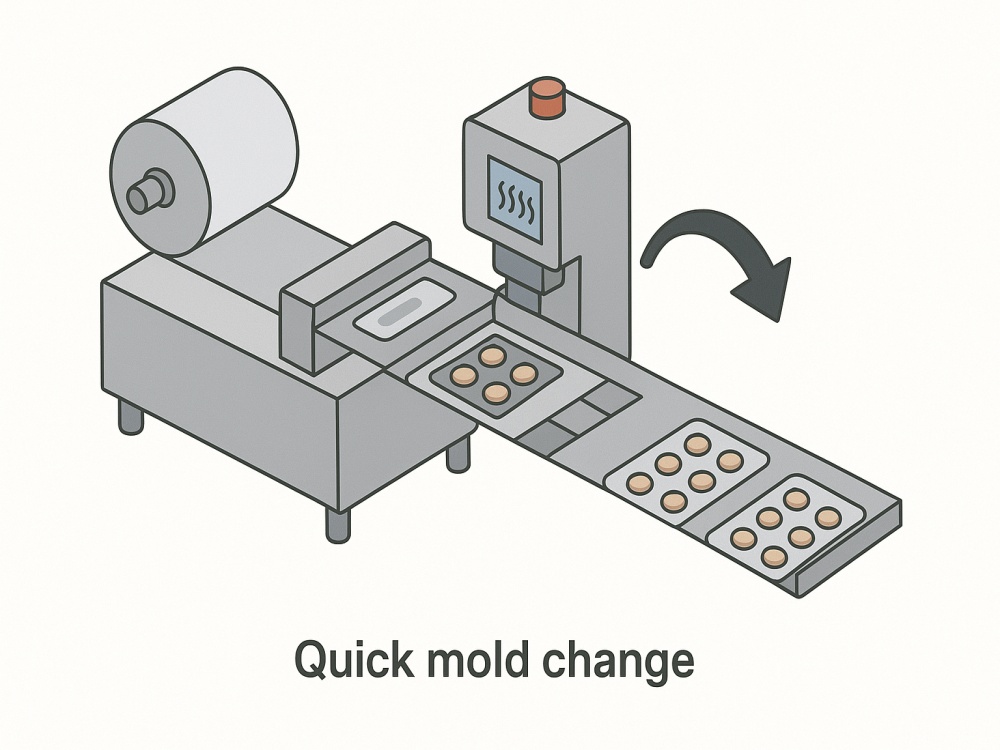

Tooling changes can be completed in minutes, ensuring fast product switching and minimal downtime—ideal for multi-product production. Tooling replacement can be completed within minutes—useful for nutraceutical brands with many formulas.

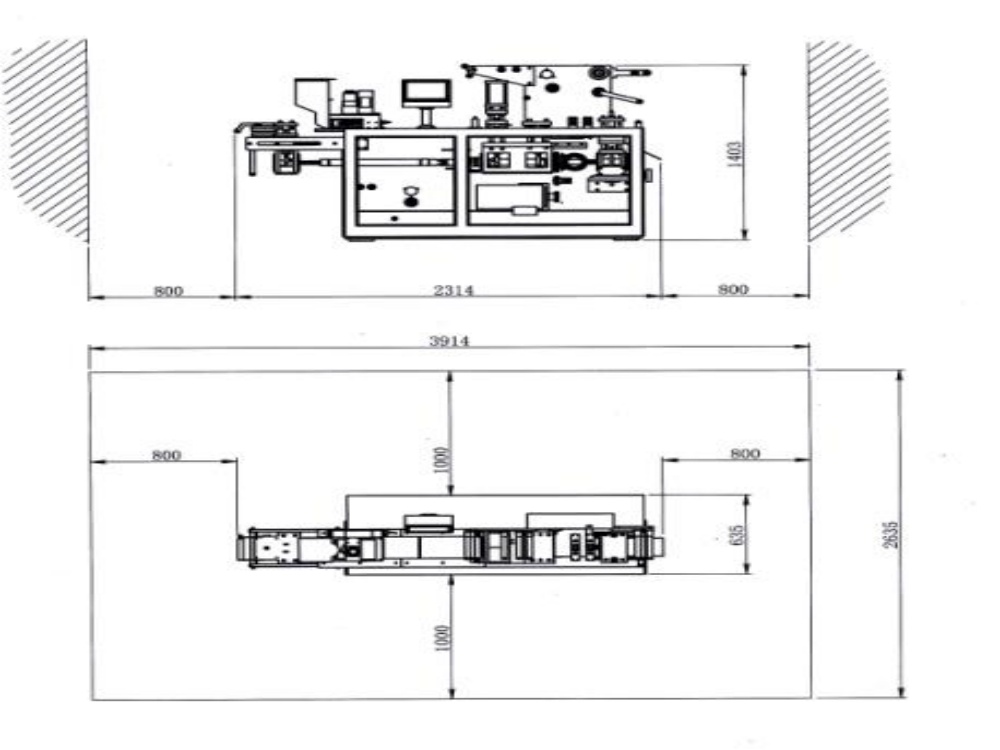

DPP 180 is engineered with a small footprint, low noise, low energy consumption & long-term durability making it suitable for small & medium factories cleanrooms, and pilot production environments. Perfect for small workshops or facilities with space limitations.

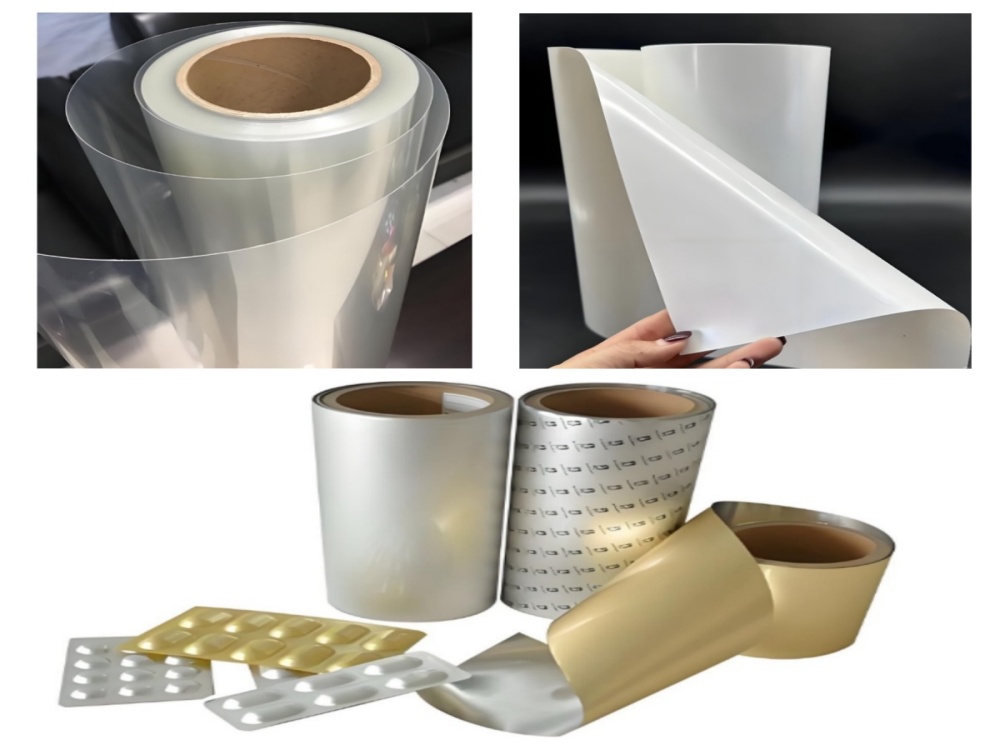

Compatible with PVC, PVDC, PET, PE, and Alu-Alu forming materials, supporting various pharmaceutical packaging requirements. PVC, PVDC, PET, Alu-Alu cold forming—covering all high-barrier packaging needs.

Punches Frequency | 25-50times/min |

Max. Forming area | 160*100mm |

Max. Forming depth | 20mm, customized |

Stroke travel range | 30-110mm |

Main power supply | 1.5kw |

PVC hard film | 0.25-0.5×180 mm |

Dialysis paper | 50-100g×180mm |

PTP Aluminum film | 0.02-0.035×180mm |

Mould cooling | Tap water or recycling water |

Overall dimension | 3050×590×1550 mm(L×W×H) |

Weight | 780kg |

Our blister pack machine design speed is 25-50times/min. The actual speed depends on the actual product and packaging material. If the products can be automatically filled by feeders, such as tablets, capsules, pills, softgels, and candies, the speed can reach 50times/min. If the product is liquid or semi-liquid, like butter, honey, or oil, the speed is 30times/min. Other irregular products feeding need manual like medical devices, small electronic components, the speed is about 25times/min. as per manual speed.

Automatic products feeding, 50times/min.

Automatic liquid filling, 30times/min.

Irregular products manual feeding, 25times/min.

The blister pack packaging machine is mainly used for the sealed packaging of small-dose products such as medicines, health supplements, food items, daily care products, and small hardware accessories. The equipment can thermoform PVC, PET, aluminum foil, and other materials into blisters, and complete automatic feeding, sealing, and cutting processes.

It provides an integrated packaging solution for moisture-proof, anti-pollution, and portable display of capsules, tablets, soft capsules, candies, and other granular and sheet-like products. It is suitable for batch production and multi-specification customization.

Blister packaging machine for tablets

Blister packaging solution for capsules

Multi-cavity blister forming for softgels

Pill blister packaging for OTC products

Disposable medical device blister packaging

Syringe component blister sealing

Surgical consumables blister forming

Vitamin tablets

Herbal capsules

Fish oil softgels

Functional gummy tablets

Hardware blister packaging

Electronic components blister packs

Battery blister packs

Pharmaceutical and nutraceutical companies increasingly require flexible blister packaging equipment that supports frequent product changes, lower batch sizes, and higher material efficiency. The DPP 180 is designed to solve these problems by offering:

The aluminum-plastic packaging form is the most commonly used method by blister machines, both practicality and economy. It is cost-effective and also achieves the effects of safety and hygiene.

Aluminum Aluminum packaging is more elegant and offers stronger protection. However, its cost is slightly higher compared to aluminum-plastic packaging. It is especially suitable for acidic, oily or products containing volatile components.

These three layers of protection combine protection and process compatibility. The outer layer has excellent barrier, The middle plastic layer helps improve molding performance and toughness, and the inner layer aluminum foil enhances sealing and chemical stability.

Customized mold design. Whether your company is in the pharmaceutical industry, the food industry, or other fields such as cosmetics, personal daily items, or small electronic products, our machines can manufacture molds according to your requirements.

Dust-free tablet feeder controls dust pollution, accurate and quantitative feeding, protects tablet integrity, realize dust-free and efficient feeding in the tablet packaging process.

The capsule brush feeder provides precise separation and positioning to ensure the integrity of the capsule. The design is simple and the turntable and brush are easy to remove and clean.

Detect product filling defects, troubleshoot packaging appearance defects, improve production quality control efficiency, screen out unqualified products, reduce labor cost.

The machine can be equipped with batch number printing to ensure full cycle traceability. Apply to the pharma and health care industries to meet the requirements of clearly expiration date and other information on products.

Alu-alu composite material is formed by cold punching to make a deep-cavity blister which is completely protected from light and has high barrier property to provide moisture-proof, oxidation-proof and light-shielding protection for the products.

Reject unqualified blister products quickly and accurately to prevent defective products from flowing into subsequent processes. Record data to assist in production optimization and ensure the efficiency and compliance of the production line.

YABO Machinery is a professional manufacturer of blister pack packaging machine, with more than 18 years of industry experience. If you are looking for a reliable DPP 180 blister pack packaging machine, YABO is your best partner.

Precision Machining Ensures Stable Blister Quality.

Fast Lead Time & Customization Capability.

OEM/ODM Customization.

Global Technical Support and Remote Service.

Complete Blister Machine Production Line Integration.

You can get a price of this model or send us any question to get any information you would like to know, we will reply to you soonest.