Blister packaging is widely used In the pharmaceutical industry, it can ensure the drug sealed sterile, accurate dosage; in the food industry, it can lock freshness, prevent pollution, extend the shelf life; in the electronics industry, it protects against static and electromagnetic damage; in the cosmetics industry, it protects skin care products and makeup from damage.

Its advantages include strong protection from external damage, customized grooves and anti-counterfeiting labels to prevent counterfeiting, transparent materials to facilitate display of products, but also to adapt to automated production lines, improve efficiency and reduce costs. It is an essential practical packaging option for many industries.

The blister packing machine’s main structure includes: forming system, filling system, heat sealing system, batch number/printing, punching system, and control system.

The blister packing machine classified by process includes thermoforming blister packing machines and cold forming blister packing machines.

VS

VS

Most flat plate forming blister packing machines are intermittent. Rotary drum vacuum forming is a continuous process.

Plastic film is heated and softened→. Mold negative pressure/positive pressure molding→ Form a bubble cavity.

| Parameter | Details | PVC | PET | Remarks |

| Heat Temperature | Upper forming mold | 120-150℃ | 160-180℃ | Excessive temperature can cause aging, while too low a temperature results in an incomplete shape. |

| Down forming mold | 60-110℃ | 80-120℃ | Auxiliary heating to prevent rapid crystallization due to excessive cooling | |

| Heat sealing temperature | 100-140℃ | 120-150℃ | Match the melting point of the aluminum foil adhesive layer, for leak-proof sealing / to prevent scorching | |

| Forming Pressure | Positive pressure forming | 0.3-0.5MPa | 0.4-0.6MPa | Uneven pressure can easily cause the blister to break / Uneven thickness can also lead to this problem. |

| Cooling Time | Cooling | 1-3second | 1.5-3.5second | Insufficient cooling causes the bubble cap to deform, and excessive length reduces efficiency. |

Product Filling Mechanism

Automatic Counting, Visual Inspection, Vibrating feeding, Manipulator.

In the heat-press sealing process of aluminum foil / composite film with PVC/PVDC base film, the sealing temperature must match the melting point of the film material.

The pressure should ensure the adhesion between the films, and the time should guarantee a complete bond. The three elements need to be precisely matched: if the temperature is too low, the pressure is insufficient, or the time is too short, the seal will be unstable.

If the temperature is too high or the time is too long, the film material may be damaged. Only when the three elements are balanced can a stable and reliable sealing strength be achieved.

Integrated design for die-cutting accuracy, waste material recovery, and finished product waste disposal.

| Model | Punch Frequency | Max. Forming Area | PVC Hard Film | PTP Aluminum Film | Dialysis Paper | Overall Dimension |

| DPP 80 | 10-33times/min | 105*70*≦12mm),

Max. Depth 25mm |

0.15-0.5*110mm | 0.02-0.035*110mm | 50-100g*110mm | 1840*590*1100 mm (L*W*H) |

| DPP 150 | 15-35times/min | 140*100*16mm | 0.25*150 mm | 0.02*150mm | 50-100g*150mm | 2450*570*1550mm (L*W*H) |

| DPP 250 | 25-60times/min | Depth Max. 20mm | 0.25-0.5*260 mm | 0.02-0.035*260mm | 50-100g*260mm | 4460*760*1620mm (L×W×H) |

| DPP 350 | 25-60times/min | Depth Max. 20mm | 0.25-0.5*350 mm | 0.02-0.035*350mm | 0.02-0.035*350mm | 4460*860*1620mm (L×W×H) |

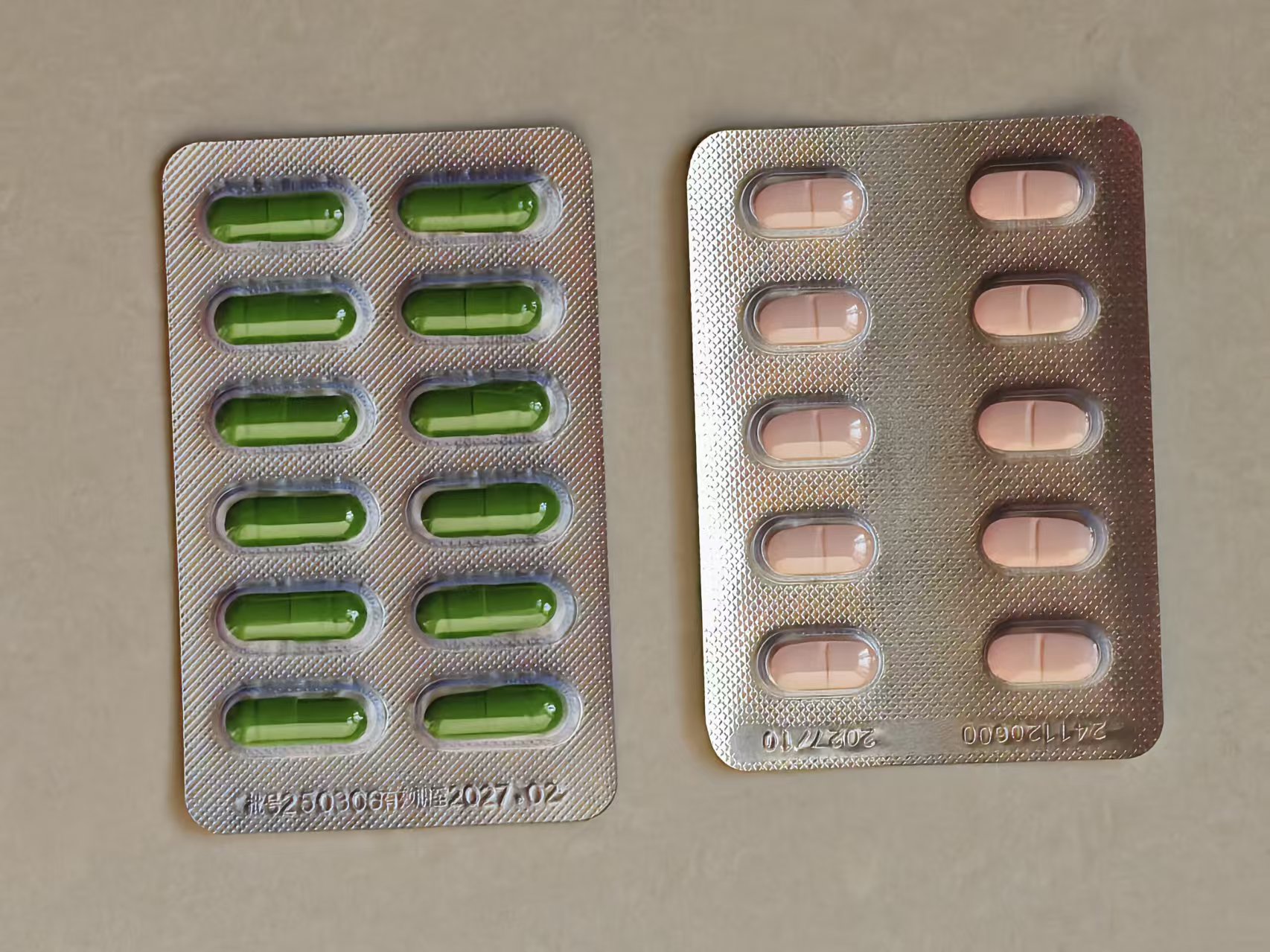

Single-dose packaging for tablets and capsules, in compliance with ISO/CE regulations

Moisture-proof and preservation measures for candies, chewing gum, and snacks.

Anti-static blister packaging for IC chips, resistors, and capacitors.

Intelligentize: PLC+HMI control, remote monitoring, fault self-diagnosis

Green and environmentally friendly: Degradable materials compatibility, energy-saving heating system.

High-speed and high-precision: Servo drive, high-speed visual inspection, AI quality inspection

Modular design: Quick mold change, flexible production, suitable for multiple SKUs

Select based on the product’s characteristics (shape, size, sensitivity)

Consider the production capacity requirements and future scalability

The significance of after-sales service, spare parts supply, and local technical support

Common faults frequently occur in blister packaging production: Poor sealing can lead to loose seals and leakage of liquid or gas. Uneven shaping can cause the blister shape to deform. Material jamming will directly halt the production line. All these problems will affect product quality and production efficiency.

The daily maintenance of the blister packaging machine is of vital importance: Regularly cleaning the molds to prevent residues from affecting the molding process, calibrating the heating plates to ensure precise temperature, and inspecting the air path to guarantee stable air pressure can effectively reduce malfunctions and extend the equipment’s lifespan.

Note: The key to extending the blister packing machine’s lifetime: Operating procedures

The blister packaging machine is the core player in intelligent manufacturing and sustainable packaging! It is compatible with automated production lines, improves efficiency and reduces consumption through intelligent control, and is compatible with degradable film materials and allowing precise control of material usage to reduce waste.

It not only meets the demand of efficient production of modern industry, but also conforms to the trend of environmental protection, helping enterprises balance production capacity and green responsibility. It is a key driving force for the upgrading and transformation of multiple industries.

This bubble packaging machine is the core product in the field of intelligent manufacturing and sustainable packaging! It is compatible with automated production lines, increases efficiency and reduces consumption through intelligent control, and is compatible with degradable film materials, allowing precise control of material usage to reduce waste.

It not only meets the demand of efficient production of modern industry, but also conforms to the trend of environmental protection, and helps enterprises balance production capacity and green responsibility. It is a key driver in the evolution of multiple industries.

We are the best manufacturer of Blister Packing and Forming Machine. We can provide professional solutions for you. Please feel free to contact us for a quick quote now!

You can get a price of this model or send us any question to get any information you would like to know, we will reply to you soonest.