We- Yabo Machinery is a trusted blister packaging machines manufacturer in the packaging industry since 2007. We focus on reliable, efficient, and cost-effective packaging solutions for pharmaceuticals, nutraceuticals, cosmetics, food, and industrial products.

As a professional manufacturer, we know your real production demands. So we develop different models from mini DPP 80 to high speed DPP 350 to meet your various capacity demands, and the machines are can be customized according to your products sizes, mold shapes, materials, capacities and packages requirements.

Every machine is designed, assembled, and tested in-house to ensure long-term durability and performance. Today, our equipment is working in 20+ countries, helping brands and factories improve productivity and reduce production costs.

To compared with European and American brands of the same level, our blister packaging machines offer higher cost-effectiveness. To compared with domestic other companies, our machine are more stable and durable.

We believe great machines bring great value — and we build every machine with that belief.

Our core expertise is strategically focused on providing turnkey solutions for critical industries. For the exacting standards of the pharmaceutical sector, we deliver blister packaging machines that adhere to stringent GMP norms, ensuring product sterility, precision dosing, and complete traceability. In the food industry, our packaging solutions prioritize hygiene and preservation, utilizing materials and technologies that extend shelf life and maintain freshness.

For cosmetics and hardware, we engineer machines that masterfully combine high-speed output with exceptional versatility, capable of handling a diverse range of product sizes, shapes, and packaging materials to create visually stunning and highly protective final packages. This specialized focus is supported by our dedicated R&D center, which continuously pioneers advancements in automation, smart control systems, and sustainable packaging processes.

Our commitment to sustainability extends beyond our machines; we have established long-term, trusted partnerships with hundreds of domestic brands, collaborating to optimize packaging lines for reduced material waste and lower energy consumption, thereby contributing to our clients’ environmental and economic goals. At YABO, we don’t just sell machines; we deliver reliable, forward-thinking packaging solutions that empower your business for the future.

Engineering Excellence, Industrial Solutions

A team of professional engineers is always available to answer technical questions and provide professional advice.

Provide high-quality, high-performance machinery and equipment to meet the production needs of a variety of companies.

Provide perfect matching solutions for the main equipment to ensure the overall effect of the production line.

Design for your unique request, we can make a custom machine service for you

Customized complete production line solutions according to customer needs.

Provide timely and professional after-sales support, including regular maintenance and emergency troubleshooting.

Professional Working Processing Steps

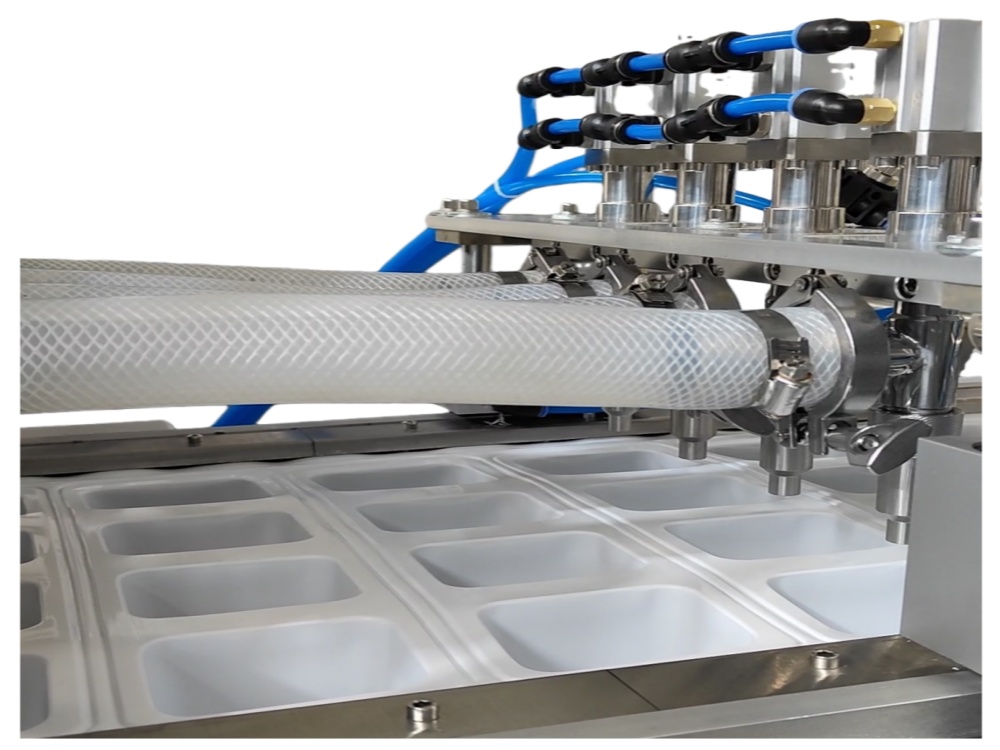

Plastic (e.g. PVC, PET, PVDC) sheets are processed into a blister structure through the action of heat and forming moulds, providing precise space for subsequent filling.

Support various materials: PVC, ALU, PET, PP, PVDC, etc.

Precision moulds ensure uniformity and no stretching and creasing of the blisters.

Suitable for different depths, sizes and zoning structures.

Thermoforming/cold forming support (e.g. ALU-ALU packaging)

Encapsulated base for tablets, capsules, syringes

Jelly and flavouring packet bases for food products.

Cosmetic eye masks, trial set shaping blisters

Hardware small accessories positioning structure (multi-compartment moulding)

Precise placement of the product into the moulded blister compartment, usually in conjunction with vibratory discharging, mechanical gripping, and visual identification systems.

High-precision feeding system to reduce waste and misloading.

Support automatic material management, material separation, visual positioning and other functions.

Adaptable to different shapes, specifications and dosage forms.

Linkage with traceability system, support code scanning and binding.

Automatic discharging of tablets, capsules and softgels in the pharmaceutical industry

Automatic placement of eye patches, ampoules and reagents in cosmetics

Jelly, candy quantitative filling in the food industry

Automatic packing of hardware and electronic components into blister compartments.

Heat-seal the top cover material (aluminium foil, composite film, etc.) onto the blister to form an airtight package to prevent moisture and pollution.

Constant temperature control to ensure sealing strength and integrity

Support printing film/aluminium foil/easy to tear film and other capping materials

Pattern alignment, hot press coding and other operations can be achieved

Good sealing effect, anti-seepage and anti-oxygen, meeting the requirements of pharmaceutical/food products.

Pharmaceutical blister sealing (PVC/ALU, ALU/ALU, ALU/PVC/ALU)

Mask, eye mask, colour cosmetics single dose product sealing

Food air-conditioned freshness sealing (MAP)

Hardware packaging blister sealing (moisture-proof and dust-proof)

Heat-seal the top cover material (aluminium foil, composite film, etc.) onto the blister to form an airtight package to prevent moisture and pollution.

High-precision die-cutting, neat edges, support for shaped punching

Optional structure such as continuous discharge, single piece discharge, punching hook, etc.

Adapt to multi-specification cutter module, quick changeover.

Support product batch number / 2D code synchronous punching and coding.

Cutting veneer for pharmaceutical blisters (whole plate/single piece).

Punching and cutting of hanging holes for retail products (e.g. hardware, batteries)

Individual strip cutting for food products (e.g. flavoured powders)

Precise slitting of cosmetic sample packs

You can get a price of this model or send us any question to get any information you would like to know, we will reply to you soonest.